In essence, furnace brazing is used to manufacture a vast range of components where strength, precision, and cleanliness are paramount. Its applications span from critical aerospace and automotive parts like heat exchangers and hydraulic fittings to delicate medical and scientific equipment, industrial turbine components, and complex machined assemblies. The process is chosen for its ability to create strong, leak-proof joints in a highly repeatable and cost-effective manner.

Furnace brazing is not just a joining method; it is a strategic manufacturing process. Its value lies in its unique ability to produce strong, complex, and distortion-free assemblies at scale, often joining materials that cannot be welded.

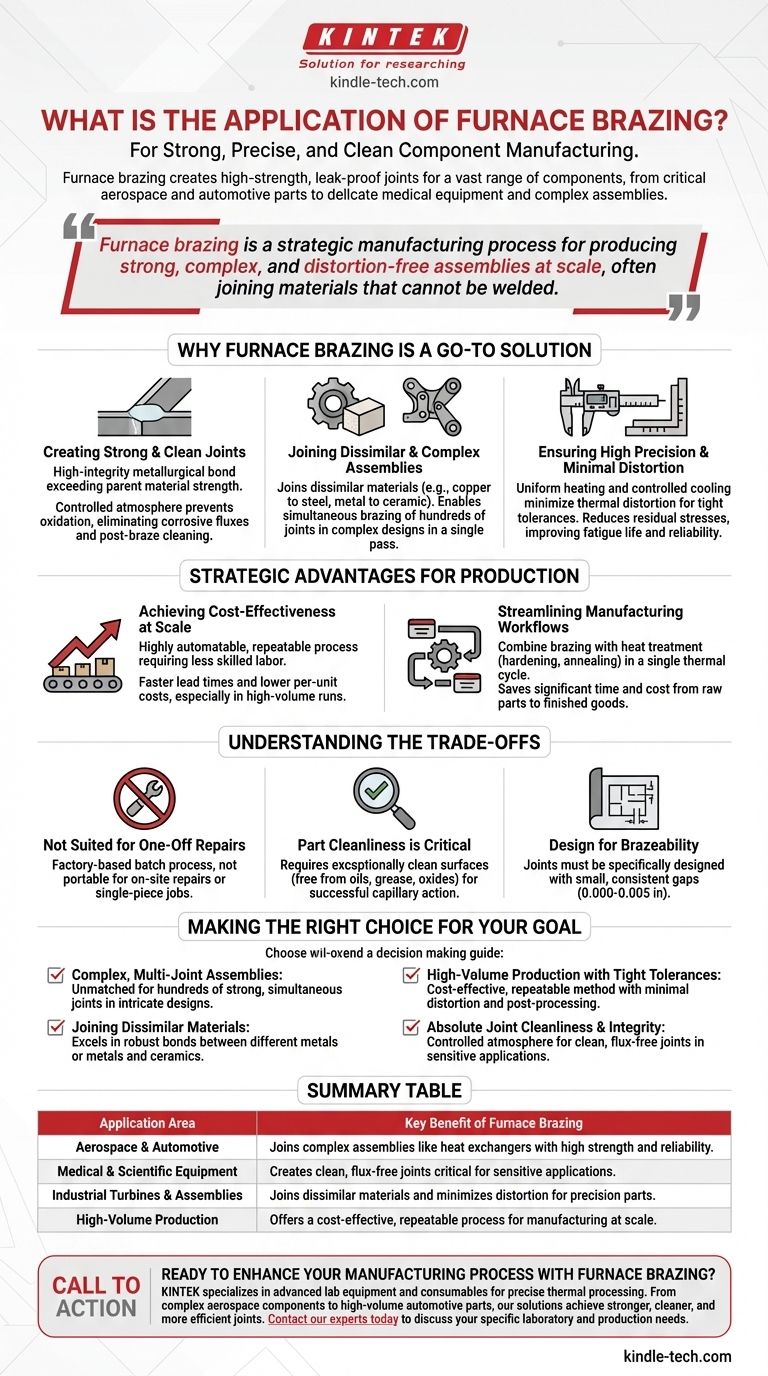

Why Furnace Brazing is a Go-To Solution

The widespread application of furnace brazing stems from a set of distinct technical advantages that solve common manufacturing challenges. It excels where other joining methods fall short, particularly in terms of joint quality and component complexity.

Creating Strong and Clean Joints

Furnace brazing produces a high-integrity metallurgical bond. The resulting joint strength can even exceed that of the parent materials being joined.

The process typically occurs in a controlled atmosphere furnace (like a vacuum or hydrogen environment). This prevents oxidation, eliminating the need for corrosive fluxes and the subsequent post-braze cleaning steps required by other methods.

Joining Dissimilar and Complex Assemblies

One of the most powerful features of furnace brazing is its ability to join dissimilar materials, such as copper to steel or even non-metals like ceramics to metals.

It also allows engineers to design incredibly complex assemblies. A single pass through the furnace can create hundreds or even thousands of joints simultaneously, a feat impossible with traditional welding.

Ensuring High Precision and Minimal Distortion

Because the entire assembly is heated and cooled uniformly, thermal distortion is minimized. This makes furnace brazing ideal for high-precision components with tight dimensional tolerances.

The slow, controlled cooling cycle also reduces residual stresses within the assembly, improving the component's fatigue life and overall reliability.

The Strategic Advantages for Production

Beyond the technical quality of the joint, furnace brazing offers significant operational benefits that make it a cost-effective and efficient choice for series production.

Achieving Cost-Effectiveness at Scale

While the initial equipment investment is high, the process is highly automatable and repeatable, requiring less skilled labor than manual welding.

The ability to braze multiple assemblies at once and the lack of post-processing lead to faster lead times and lower per-unit costs, especially in high-volume production runs.

Streamlining Manufacturing Workflows

Furnace brazing can be uniquely combined with heat treatment processes. An assembly can be brazed and simultaneously hardened or annealed in a single thermal cycle.

This consolidation of manufacturing steps saves significant time and cost, streamlining the entire production workflow from raw parts to finished goods.

Understanding the Trade-offs

While powerful, furnace brazing is not a universal solution. Understanding its operational context is key to leveraging it correctly.

Not Suited for One-Off Repairs

The process relies on a furnace, making it a factory-based batch process. It is not portable and cannot be used for on-site repairs or single-piece jobs where setup costs would be prohibitive.

Part Cleanliness is Critical

The success of furnace brazing depends on capillary action, where the molten filler metal is drawn into a tight-fitting joint. This requires the component surfaces to be exceptionally clean, free from oils, grease, and oxides before entering the furnace.

Design for Brazeability

Joints must be designed specifically for brazing, with consistent, small gaps (typically 0.000 to 0.005 inches) to allow capillary action to work effectively. This requires consideration early in the component design phase.

Making the Right Choice for Your Goal

To determine if furnace brazing is the correct process for your project, consider your primary objective.

- If your primary focus is complex, multi-joint assemblies: Furnace brazing is unmatched for creating hundreds of strong, simultaneous joints in intricate designs that would otherwise be impossible to manufacture.

- If your primary focus is joining dissimilar materials: The process excels where traditional welding fails, enabling robust bonds between different metals or even between metals and ceramics.

- If your primary focus is high-volume production with tight tolerances: Furnace brazing offers a cost-effective, highly repeatable method that minimizes distortion and reduces the need for costly post-processing.

- If your primary focus is absolute joint cleanliness and integrity: The controlled atmosphere ensures perfectly clean joints free from flux residue, which is critical for medical, hydraulic, and vacuum applications.

Ultimately, adopting furnace brazing allows you to manufacture higher-performing, more reliable, and more complex components efficiently and at scale.

Summary Table:

| Application Area | Key Benefit of Furnace Brazing |

|---|---|

| Aerospace & Automotive | Joins complex assemblies like heat exchangers with high strength and reliability. |

| Medical & Scientific Equipment | Creates clean, flux-free joints critical for sensitive applications. |

| Industrial Turbines & Assemblies | Joins dissimilar materials and minimizes distortion for precision parts. |

| High-Volume Production | Offers a cost-effective, repeatable process for manufacturing at scale. |

Ready to enhance your manufacturing process with furnace brazing?

KINTEK specializes in the advanced lab equipment and consumables needed for precise thermal processing. Whether you are developing complex aerospace components, reliable medical devices, or high-volume automotive parts, our solutions can help you achieve stronger, cleaner, and more efficient joints.

Contact our experts today to discuss how we can support your specific laboratory and production needs.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why would you braze instead of weld? Preserve Material Integrity and Join Dissimilar Metals

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- What is a braze repair process? A Low-Heat Solution for Strong, Seamless Metal Joining

- What are the advantages of brazing compared to welding? Achieve Clean, Low-Distortion Metal Joining