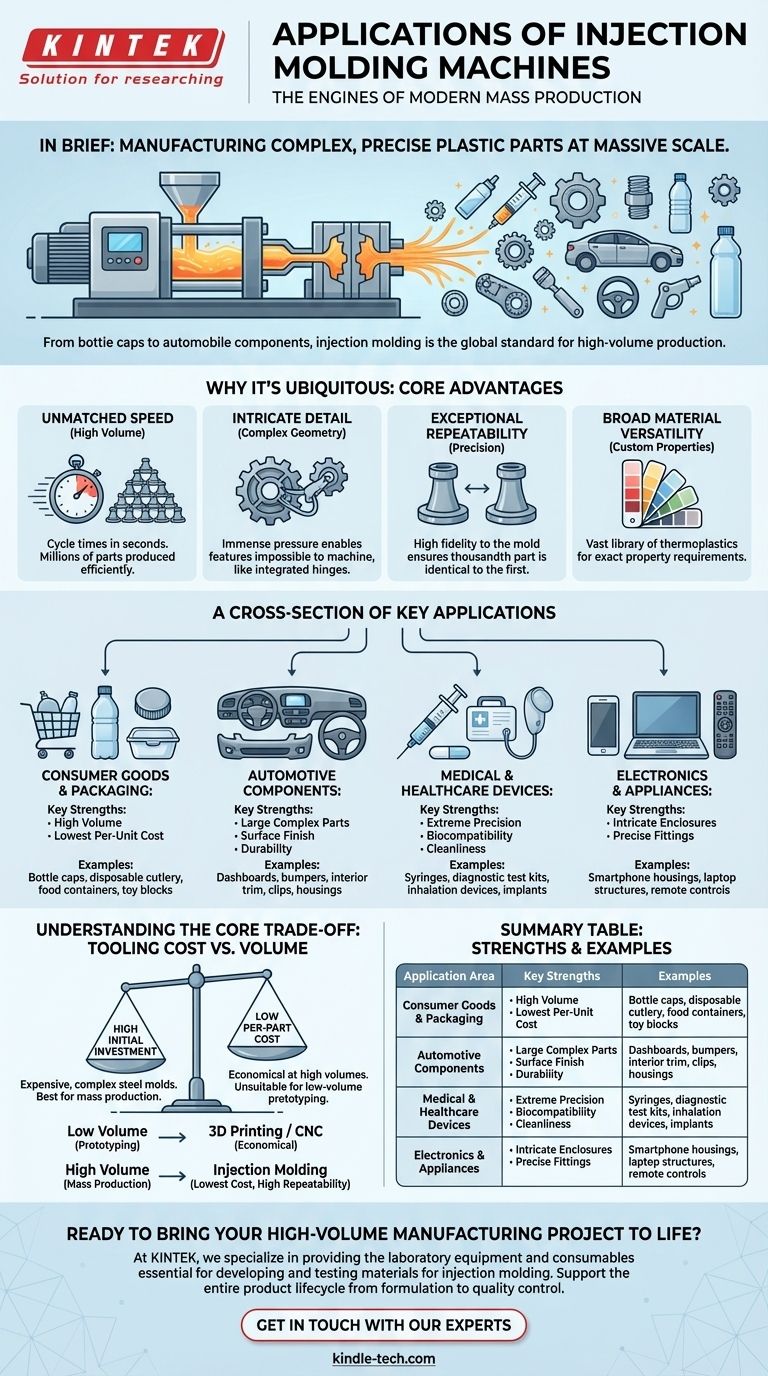

In short, injection molding machines are the engines of modern mass production. They are used to manufacture an enormous array of plastic parts by injecting molten material into a precisely engineered mold. This process is responsible for everything from simple bottle caps and children's toys to highly complex components used in automobiles, medical devices, and consumer electronics.

The true power of injection molding isn't just in the items it creates, but in its unique combination of capabilities. This process is the global standard for producing complex, highly precise plastic parts at a massive scale, making it the economic backbone of countless industries.

Why Injection Molding is So Ubiquitous

The dominance of injection molding stems from a few core advantages that are difficult to achieve with other manufacturing methods. These principles explain why it is chosen for such a diverse range of products.

Unmatched Speed for High Volume

Once the initial mold is created and the machine is set up, parts can be produced with cycle times measured in seconds. This incredible speed allows for the production of millions of identical parts efficiently.

Intricate Detail and Complex Geometry

The process forces molten plastic into a mold under immense pressure. This allows for the creation of incredibly detailed and complex shapes, including features like strengthening ribs, screw bosses, and integrated hinges, which would be costly or impossible to machine.

Exceptional Repeatability

An injection molding machine produces parts with extremely high fidelity to the original mold. This ensures that the thousandth or millionth part is virtually identical to the first, a critical requirement for components that must fit together perfectly.

Broad Material Versatility

A vast library of thermoplastic polymers can be used in injection molding. This allows engineers to select a material with the exact properties required, whether it be for strength, flexibility, optical clarity, chemical resistance, or color.

A Cross-Section of Key Applications

By grouping applications, we can see how the core strengths of injection molding are leveraged across different industries.

Consumer Goods and Packaging

This is the most visible application, including items like food containers, bottle caps, disposable cutlery, and toy building blocks. Here, the primary drivers are extremely high volume and the lowest possible per-unit cost.

Automotive Components

The automotive industry relies heavily on injection molding for parts like dashboards, bumpers, interior trim panels, and small functional components like clips and housings. The key benefits are the ability to create large, complex parts with a high-quality surface finish and excellent durability.

Medical and Healthcare Devices

Injection molding is critical for producing medical products such as syringes, diagnostic test kits, inhalation devices, and even some implantable components. The process is chosen for its extreme precision, cleanliness, and ability to work with specialized, biocompatible polymers in a sterile environment.

Electronics and Appliances

Nearly every electronic device you own has injection-molded parts, from the housing of your smartphone and TV remote to the internal structural components of a laptop. The process is essential for creating intricate enclosures with precise openings for buttons, screens, and connectors.

Understanding the Core Trade-off: Tooling Cost

Despite its advantages, injection molding is not the right choice for every situation. Its primary limitation is the significant upfront investment required.

The High Initial Investment

The "mold" or "tool" is a highly complex piece of machinery, typically machined from hardened steel. Creating this tool is a time-consuming and expensive process, with costs ranging from a few thousand dollars for a simple part to hundreds of thousands for a large, complex one.

The Break-Even Point

The high cost of the tool means injection molding only becomes economical at high production volumes. The initial investment is amortized over the total number of parts produced, which is why it excels for mass-market products but is unsuitable for one-off prototypes.

The Lack of Flexibility

Once a steel mold is manufactured, making design changes is difficult and expensive. The design must be finalized and thoroughly tested before committing to tooling, as modifications are often impractical. This is a stark contrast to more agile processes like 3D printing.

Making the Right Choice for Your Goal

To determine if injection molding is the correct process, you must weigh its high upfront costs against its low per-part cost at scale.

- If your primary focus is mass production (thousands to millions of units): Injection molding offers the lowest per-part cost and highest repeatability, making it the default choice.

- If your primary focus is prototyping or low-volume production (1 to hundreds of units): The high tooling cost makes injection molding unsuitable; processes like 3D printing or CNC machining are far more economical.

- If your primary focus is a complex part with high precision: Injection molding is an excellent technical choice, but only if you can justify the tooling cost with sufficient production volume.

Understanding this balance between volume and tooling cost is the key to leveraging the power of injection molding effectively.

Summary Table:

| Application Area | Key Strengths | Examples |

|---|---|---|

| Consumer Goods & Packaging | High Volume, Low Per-Unit Cost | Bottle caps, food containers, toys |

| Automotive Components | Complex Parts, Durability, Surface Finish | Dashboards, bumpers, interior trim |

| Medical & Healthcare Devices | High Precision, Biocompatible Materials | Syringes, diagnostic kits, implants |

| Electronics & Appliances | Intricate Enclosures, Precise Fitting | Smartphone housings, laptop components |

Ready to bring your high-volume manufacturing project to life?

At KINTEK, we specialize in providing the laboratory equipment and consumables essential for developing and testing materials for injection molding. Whether you're formulating new polymers or ensuring quality control for mass production, our solutions support the entire product lifecycle.

Contact us today to discuss how we can equip your lab for success. Let's build the future of manufacturing, together.

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Double Plate Heating Press Mold for Lab

- Powerful Plastic Crusher Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is the manufacturing process of rubber molding? Injection, Compression, or Transfer Molding?

- What are the parameters to be considered for selecting the thin wall molding machine? Key Specs for High-Speed Production

- What can you make with an injection moulding machine? Mass-Produce High-Quality Plastic Parts Efficiently

- What is a positive of injection moulding? Achieve High-Volume Production with Unmatched Efficiency

- What is molding technique? A Guide to High-Volume, Complex Part Manufacturing