At its core, Spark Plasma Sintering (SPS) is applied to rapidly create dense, high-performance materials that are difficult or impossible to produce with conventional methods. Its applications focus on advanced materials like high-performance ceramics, refractory metals with high melting points, novel composites, and amorphous materials. It is also uniquely capable of joining, or welding, dissimilar materials such as a metal to a ceramic.

The central value of Spark Plasma Sintering is not just in solidifying powders, but in its ability to do so with exceptional speed and at lower temperatures. This unique combination of speed and control preserves delicate microstructures, enabling the creation of advanced materials with superior properties.

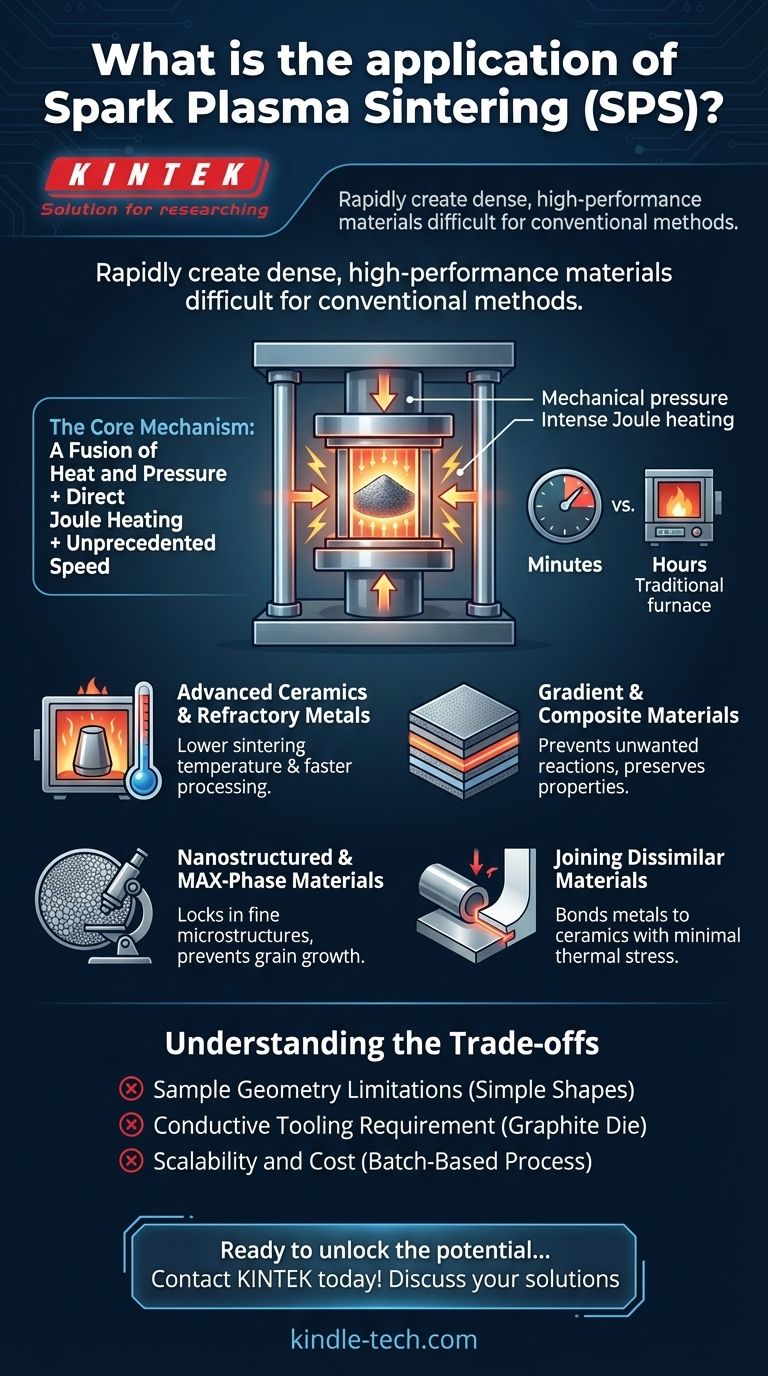

What Makes SPS Different? The Core Mechanism

To understand its applications, you must first understand why the SPS process is fundamentally different from traditional furnace-based sintering. The difference lies in how it delivers energy to the material.

A Fusion of Heat and Pressure

Like hot pressing, SPS places a powdered material into a die (typically graphite) and applies a strong uniaxial (single-direction) mechanical pressure. This pressure forces the particles into close contact, which is the first step toward bonding.

Direct Joule Heating

The defining feature of SPS is its heating method. Instead of relying on external heating elements to radiate heat inward, SPS passes a high-power electrical current (usually pulsed DC) directly through the conductive die and, in many cases, through the material itself. This generates intense Joule heat from within, heating the sample both internally and externally.

The Impact of Unprecedented Speed

This direct heating method allows for extremely rapid heating rates, sometimes as high as 1000°C per minute. Sintering cycles that take many hours in a conventional furnace can be completed in minutes with SPS. This speed is the key to most of its unique applications.

Key Applications Driven by SPS Advantages

The unique mechanism of SPS unlocks capabilities that directly translate to specific, high-value applications where conventional methods fall short.

Advanced Ceramics and Refractory Metals

Materials like tungsten, molybdenum, and technical ceramics have extremely high melting points. Sintering them conventionally requires very high temperatures and long hold times. SPS can achieve full densification at temperatures several hundred degrees lower, saving energy and dramatically shortening processing time.

Gradient and Composite Materials

When creating a composite from multiple materials, long exposure to high heat can cause unwanted chemical reactions or diffusion between the layers. The extreme speed of SPS consolidates the material before these detrimental reactions have time to occur, preserving the distinct properties of each component.

Nanostructured and MAX-Phase Materials

Nanomaterials and other advanced phases (like MAX phases) derive their unique properties from their fine-grained microstructure. The slow heating of conventional sintering allows these fine grains to grow and coarsen, destroying the material's beneficial properties. SPS sinters the material so quickly that it "locks in" the desired nanostructure before it can degrade.

Joining Dissimilar Materials

SPS can be used as a specialized welding technique to bond materials that are typically incompatible, such as a ceramic to a metal. The localized, rapid heating creates a strong diffusion bond at the interface without causing the bulk materials to crack or warp from thermal stress.

Understanding the Trade-offs and Considerations

While powerful, SPS is a specialized tool, not a universal solution. Its advantages come with inherent limitations.

Sample Geometry Limitations

The use of a rigid die and uniaxial pressure means SPS is best suited for producing simple shapes, such as discs, pellets, and rectangular plates. It is not an effective method for creating components with complex, three-dimensional geometries.

Conductive Tooling Requirement

The process relies on a conductive die, almost always made of graphite. This tooling is a consumable component, can be expensive, and limits the processing atmosphere. This adds to the operational cost and complexity compared to standard furnace sintering.

Scalability and Cost

SPS is a high-performance, batch-based process. While excellent for research, prototyping, and small-scale production of advanced components, it is generally less cost-effective for the mass production of simple parts compared to conventional sintering methods.

Making the Right Choice for Your Goal

Selecting SPS depends entirely on whether the material's performance justifies the process's specialization and cost.

- If your primary focus is material innovation: SPS is the ideal tool for creating novel composites, functionally graded materials, and nanostructured components that are inaccessible with other methods.

- If your primary focus is preserving microstructure: For any material where maintaining fine grain size is critical to performance, the rapid heating and cooling of SPS is a decisive advantage.

- If your primary focus is processing speed for difficult materials: When working with refractory metals or ceramics, SPS can reduce manufacturing time from a full day to under an hour.

- If your primary focus is mass-producing simple metal parts: For high-volume applications where ultimate performance is not the main driver, traditional, cost-effective sintering techniques remain the better choice.

Ultimately, Spark Plasma Sintering is the definitive choice when you need to exert precise control over a material's final microstructure under extreme time constraints.

Summary Table:

| Application Area | Key Benefit of SPS |

|---|---|

| Advanced Ceramics & Refractory Metals | Lower sintering temperature & faster processing |

| Gradient & Composite Materials | Prevents unwanted reactions, preserves properties |

| Nanostructured & MAX-Phase Materials | Locks in fine microstructures, prevents grain growth |

| Joining Dissimilar Materials | Bonds metals to ceramics with minimal thermal stress |

Ready to unlock the potential of advanced materials in your lab?

KINTEK specializes in providing state-of-the-art lab equipment and consumables for materials research and development. Our expertise in sintering technologies can help you achieve faster processing times, preserve delicate microstructures, and create novel composites that are impossible with conventional methods.

Contact us today to discuss how our solutions can accelerate your materials innovation and bring your high-performance projects to life!

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- How to reduce porosity in powder metallurgy? Optimize Compaction and Sintering for Denser Parts

- Is Bio Energy renewable? Unpacking the Sustainability of Biomass Power

- What is the physical Vapour deposition method for synthesis of nanomaterials? Achieve Atomic-Level Precision

- Does platinum oxidize? The Truth About Its Extreme Corrosion Resistance

- What are the advantages and disadvantages of filter press? Unlock Superior Solid-Liquid Separation

- How does a high-precision MFC regulate argon flow for alpha-Al2O3 coating? Optimize Your Deposition Process Quality

- What are the precautions for heat in the laboratory? Essential Safety Rules to Prevent Burns and Fires

- What is the application of pyrolysis in waste management? Unlock Waste into Energy & Resources