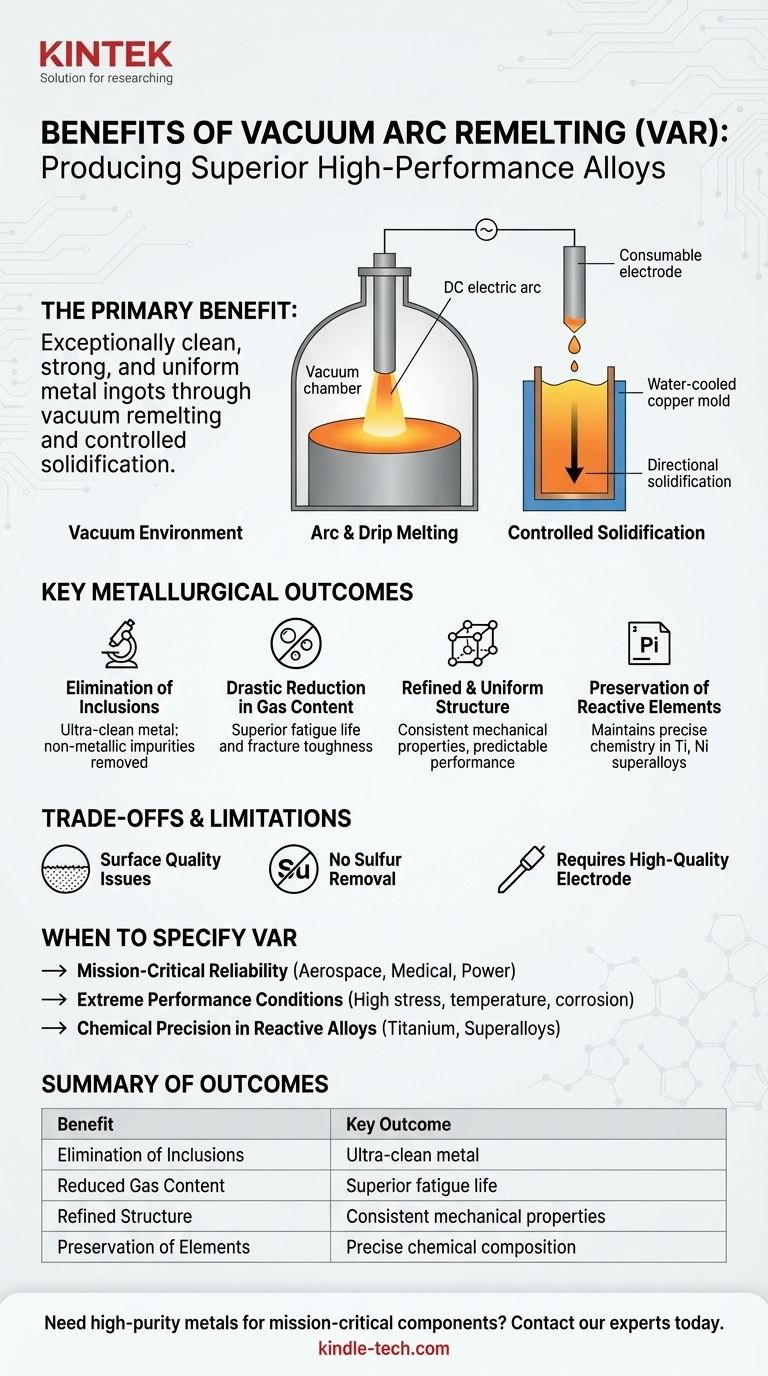

The primary benefit of Vacuum Arc Remelting (VAR) is its ability to produce exceptionally clean, strong, and uniform metal ingots. It achieves this by remelting a metal electrode in a vacuum, which removes dissolved gases and impurities, while a controlled solidification process refines the material's internal structure. This makes it an essential process for creating high-performance alloys used in critical applications.

Vacuum Arc Remelting is not simply a melting method; it is a comprehensive refining process. It leverages a high-temperature arc and a vacuum environment to purify the metal and precisely control its solidification, resulting in a final product with a level of structural integrity and cleanliness that conventional methods cannot achieve.

How VAR Achieves Superior Metal Quality

The benefits of VAR are a direct result of its unique operational principles. Each stage of the process is designed to systematically remove defects and enhance the material's fundamental properties.

The Role of the Vacuum

The defining feature of the process is the vacuum environment. This prevents the molten metal from reacting with atmospheric gases like oxygen and nitrogen, which would otherwise form undesirable inclusions and compromise the alloy's properties.

Crucially, the vacuum also pulls dissolved gases, such as hydrogen, out of the liquid metal. This significantly reduces the risk of hydrogen embrittlement and porosity, producing a denser and more reliable final ingot.

The Arc and Drip Melting Process

VAR uses a consumable electrode—a solid bar of the alloy to be refined—which is remelted by a powerful DC electric arc. The tip of the electrode melts at extremely high temperatures (approaching 5000K), forming small droplets.

As these droplets fall through the arc and the vacuum, they are exposed to intense heat and low pressure. This volatilizes and removes low-melting-point impurities like lead, bismuth, and other tramp elements, further purifying the alloy.

Controlled Solidification

The purified metal droplets collect in a water-cooled copper mold below. Because the cooling is managed from the bottom up, the solidification is highly directional and controlled.

This process minimizes segregation, where different elements in the alloy separate during cooling. It results in a uniform, fine-grained crystalline structure, a smaller shrinkage cavity at the top of the ingot, and a higher overall material yield.

The Key Metallurgical Outcomes

The combination of these process steps delivers tangible improvements in the final material, making it suitable for the most demanding environments.

Elimination of Inclusions

The process is exceptionally effective at removing non-metallic inclusions. Some are broken down by the arc's heat, while the vacuum environment prevents new ones from forming, leading to an ultra-clean metal.

Drastic Reduction in Gas Content

By removing dissolved hydrogen and nitrogen, VAR produces metals with superior fatigue life and fracture toughness. Materials designated with "HV" for high-vacuum often indicate this level of refinement.

A Refined and Uniform Crystalline Structure

The controlled cooling ensures a consistent microstructure throughout the ingot. This uniformity is critical for predictable mechanical properties, such as strength and ductility, across the entire component.

Preservation of Reactive Elements

For alloys containing reactive elements like titanium and aluminum, the vacuum is essential. It prevents these valuable elements from burning off or oxidizing, ensuring the final chemical composition is precisely maintained.

Understanding the Trade-offs and Limitations

While VAR produces superior materials, it is a secondary refining process with specific constraints that are important to understand.

Surface Quality Issues

The intense arc action can cause molten metal to splash against the mold wall, resulting in a rough and porous ingot surface. This surface layer often has a higher concentration of inclusions and must be machined off, or "peeled," before further processing.

Inability to Remove Sulfur

The VAR process has no mechanism for desulfurization. Therefore, the initial consumable electrode must already have a very low sulfur content, as any sulfur present will remain in the final product.

Requirement for a High-Quality Electrode

VAR is a remelting process, not a primary melt. It requires a pre-formed consumable electrode, which is often produced using another advanced method like Vacuum Induction Melting (VIM). This two-step approach adds to the overall complexity and cost of production.

When to Specify Vacuum Arc Remelting

Choosing VAR is a strategic decision based on the non-negotiable performance requirements of the final component.

- If your primary focus is mission-critical reliability: Specify VAR for applications in aerospace, medical implants, or power generation where component failure would be catastrophic.

- If your primary focus is performance under extreme conditions: Use VAR for materials exposed to high stress, extreme temperatures, or corrosive environments that demand superior fatigue life and fracture toughness.

- If your primary focus is chemical precision in reactive alloys: Employ VAR for titanium, nickel-based superalloys, and specialty steels where maintaining the exact alloy chemistry is paramount to performance.

Ultimately, specifying Vacuum Arc Remelting is a commitment to achieving the highest possible material purity and structural integrity for components that simply cannot fail.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Elimination of Inclusions | Ultra-clean metal with non-metallic impurities removed |

| Drastic Reduction in Gas Content | Superior fatigue life and fracture toughness |

| Refined, Uniform Structure | Consistent mechanical properties and predictable performance |

| Preservation of Reactive Elements | Maintains precise chemical composition of alloys like titanium and nickel superalloys |

Need high-purity metals for mission-critical components?

At KINTEK, we specialize in providing the advanced laboratory equipment and consumables necessary for processes like Vacuum Arc Remelting. Our solutions help you produce metals with the structural integrity and cleanliness required for aerospace, medical implants, and power generation applications.

Let's discuss how we can support your lab's needs. Contact our experts today to explore the right equipment for your high-performance alloy production.

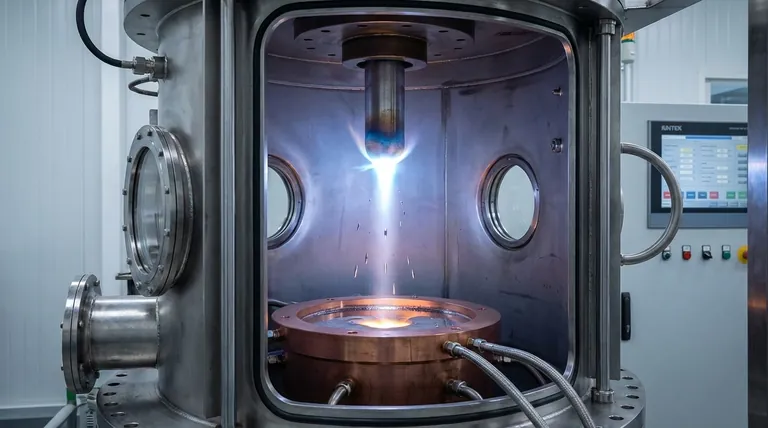

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the maximum frequency of induction heaters? Mastering Frequency for Optimal Heating Results

- What materials can be induction heated? A Guide to Metals, Conductivity, and Heating Efficiency

- Do induction furnaces work on AC or DC? Unlocking the Power of Alternating Current

- What is the difference between resistance heating and induction heating? Choose the Right Method for Your Needs

- How to calculate induction heating power? A Guide to Accurate System Sizing

- What does VAR mean steel? A Guide to Vacuum Arc Remelting for High-Purity Steel

- What is the primary function of a vacuum induction furnace in the preparation of silicon-containing T91 steel?

- What are the three main components of an induction heating system? Power Supply, Coil, and Workpiece Explained