There is no single "best" material for a crucible. The ideal choice is entirely dependent on the specific metal you are melting, its required temperature, and the type of furnace you are using. The most common high-performance materials are graphite, clay-graphite, and advanced ceramics like silicon carbide.

The core principle is one of matching the tool to the task. The "best" crucible is not the most expensive or the most heat-resistant in absolute terms, but the one whose properties of temperature resistance, chemical inertness, and thermal shock tolerance best align with your specific metalworking goals.

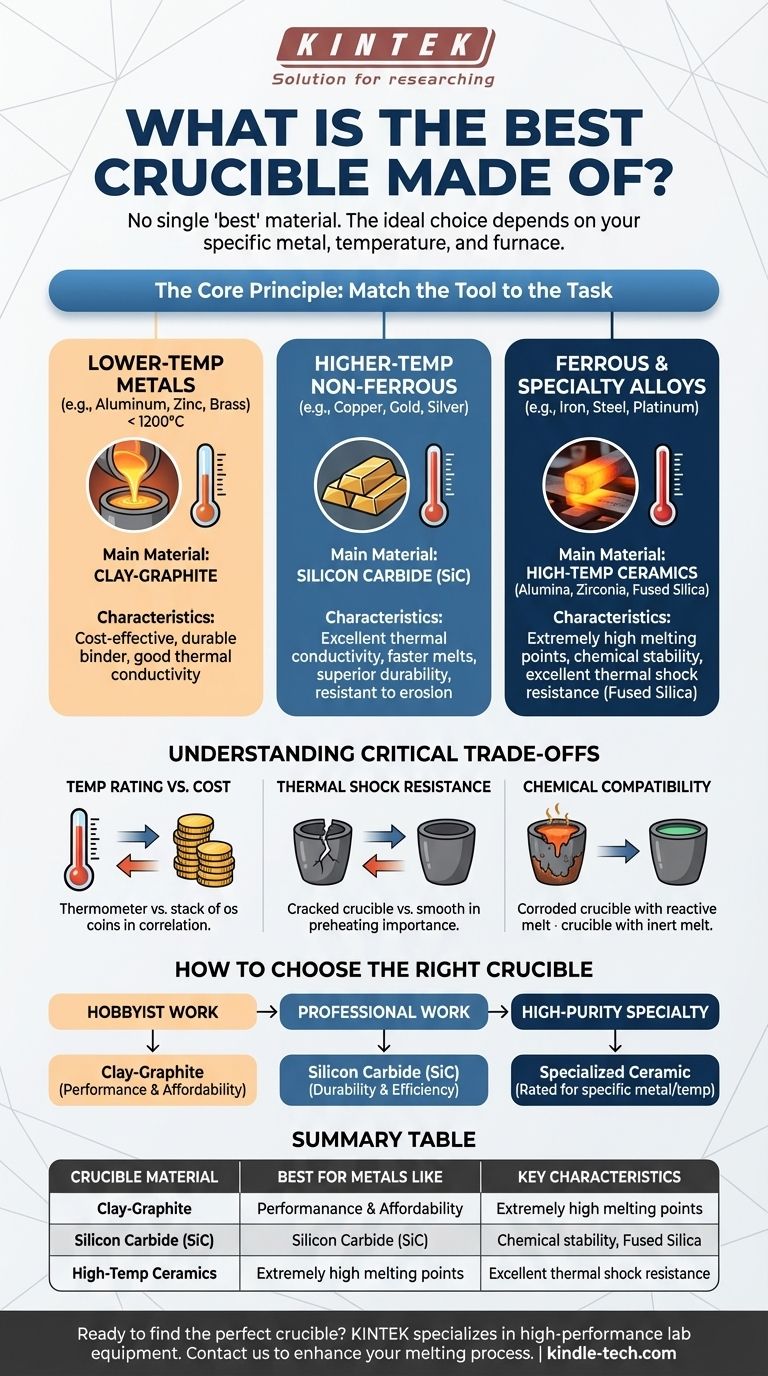

Matching the Crucible Material to the Application

The primary factor dictating your choice of crucible is the melting point and chemical nature of the metal you intend to work with. A material that is perfect for aluminum will fail when used for iron.

For Lower-Temperature Metals (e.g., Aluminum, Zinc, Brass)

For metals melting below approximately 1200°C (2200°F), clay-graphite crucibles are the most common and cost-effective choice.

The combination of clay as a binder and graphite for thermal conductivity creates a durable and efficient vessel for hobbyists and many professional applications. They offer good performance for their price point.

For Higher-Temperature Non-Ferrous Metals (e.g., Copper, Gold, Silver)

When working with metals that require higher temperatures or when seeking greater durability and efficiency, silicon carbide (SiC) crucibles are a superior option.

These are typically a composite of silicon carbide and graphite. They possess excellent thermal conductivity, leading to faster melt times and better fuel efficiency. They are also significantly more durable and resistant to erosion than standard clay-graphite crucibles.

For Ferrous Metals and Specialty Alloys (e.g., Iron, Steel, Platinum)

Melting iron, steel, and other high-temperature alloys pushes beyond the limits of common crucibles. These applications demand specialized high-temperature ceramic crucibles.

Materials like alumina, zirconia, or magnesia are used for their extremely high melting points and chemical stability. For high-purity melts, especially with precious metals, fused silica (quartz) is often chosen for its exceptional thermal shock resistance and inertness, preventing contamination of the final product.

Understanding the Critical Trade-offs

Choosing a crucible involves balancing performance characteristics. Understanding these trade-offs is key to avoiding costly failures and achieving a successful melt.

Temperature Rating vs. Cost

There is a direct and steep correlation between a crucible's maximum service temperature and its cost. A basic clay-graphite crucible might be relatively inexpensive, while a high-purity zirconia crucible for specialty alloys can cost orders of magnitude more.

Thermal Shock Resistance

Thermal shock is the stress a material endures when its temperature changes rapidly, often leading to cracks and catastrophic failure.

A crucible must always be preheated gently before being charged and exposed to full heat. Materials like fused silica are exceptionally resistant to thermal shock, while some ceramics can be more brittle and require a very careful heating cycle.

Chemical Compatibility

Molten metals and the fluxes used to purify them can be highly reactive. The wrong crucible material can be actively attacked and dissolved by the melt, which both ruins the crucible and contaminates your metal.

It is critical to ensure your chosen crucible material is chemically inert to the specific metals and additives you plan to use.

How to Choose the Right Crucible

Base your decision on your most common and demanding use case.

- If your primary focus is hobbyist work with aluminum, zinc, or brass: A clay-graphite crucible provides the best balance of performance and affordability.

- If your primary focus is professional work with copper, bronze, or precious metals: Investing in a silicon carbide (SiC) crucible will pay for itself in durability, longevity, and furnace efficiency.

- If your primary focus is melting iron, steel, or high-purity specialty metals: You must select a specialized ceramic crucible (alumina, fused silica, etc.) rated specifically for that metal and temperature range.

Ultimately, selecting the correct crucible is a foundational step for ensuring a safe, efficient, and successful melt.

Summary Table:

| Crucible Material | Best For Metals Like | Key Characteristics |

|---|---|---|

| Clay-Graphite | Aluminum, Zinc, Brass | Cost-effective, durable for temps <1200°C |

| Silicon Carbide (SiC) | Copper, Gold, Silver | High thermal conductivity, durable, efficient |

| High-Temp Ceramics (Alumina, Zirconia, Fused Silica) | Iron, Steel, Platinum | Extreme heat resistance, chemical inertness |

Ready to find the perfect crucible for your lab's specific needs? KINTEK specializes in high-performance lab equipment and consumables, including a wide range of crucibles designed for precise temperature control and chemical compatibility. Whether you're melting aluminum or high-purity alloys, our experts can help you select the right tool for safe, efficient results. Contact us today to enhance your melting process and ensure successful outcomes!

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- High Purity Pure Graphite Crucible for Evaporation

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

People Also Ask

- Do you have to temper your crucible? A Critical Safety Step for Melting Metal

- What is the temperature range of an aluminum crucible? Ensure Accurate Thermal Analysis in Your Lab

- Why are alumina crucibles and mother powder used for LLZO sintering? Master Lithium Stability in Solid-State Ceramics

- What is the function of ceramic crucibles during the industrial chemical analysis of charcoal? Enhance Data Accuracy

- What role does a corundum crucible play in vacuum carbothermic reduction? Ensuring Chemical Purity and Stability

- Why is a corundum crucible preferred for high-purity magnesium? Achieve 99.999% Purity Without Contamination

- What are the advantages of using alumina crucibles for the TGA of modified alkyd resins? Ensure Accurate Results

- What are the advantages of a crucible furnace? Achieve Versatile Melting with Precision and Control