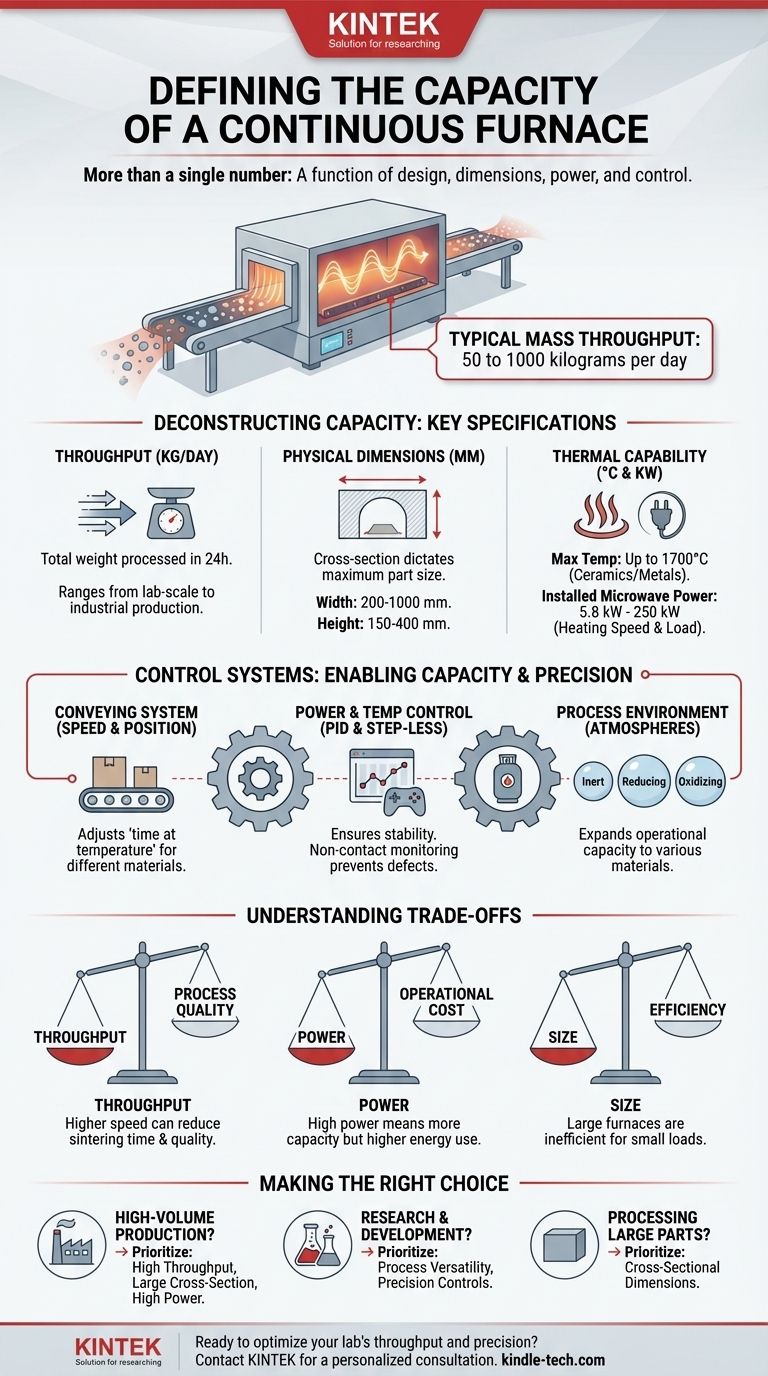

The capacity of a continuous furnace is not a single number but a function of its design and purpose. For a modern continuous microwave sintering furnace, the material throughput capacity typically ranges from 50 to 1000 kilograms per day. This output is directly influenced by the furnace's physical dimensions, its installed power, and the sophistication of its control systems.

A furnace's true capacity is defined by more than its daily throughput. It is a comprehensive measure of its physical dimensions, thermal power, and process control precision, which together determine its suitability for a specific manufacturing or research task.

Deconstructing Furnace Capacity: The Key Specifications

To properly evaluate a continuous furnace, you must look beyond the headline throughput number and analyze the core specifications that dictate its performance. These factors determine what you can process, how large it can be, and how fast you can do it.

Throughput: The Core Metric

The most common measure of capacity is mass throughput, stated in kilograms per day (kg/day). The wide range of 50 to 1000 kg/day reflects the vast difference between smaller, lab-scale models and large, industrial production units.

This figure represents the total weight of material the furnace can successfully process within a 24-hour period while meeting all quality requirements.

Physical Dimensions: The Volumetric Constraint

The internal cross-section of the furnace tunnel dictates the maximum size of the parts you can process. A typical furnace has a width of 200 to 1000 mm and a height of 150 to 400 mm.

This physical limitation is often more critical than daily throughput. A furnace with high throughput is useless if your components cannot physically fit inside it.

Thermal Capability: The Processing Engine

The furnace's ability to heat material is determined by its temperature range and power. A maximum process temperature of up to 1700°C allows for the sintering of advanced ceramics and metals.

Installed microwave power, ranging from 5.8 kW to 250 kW, directly correlates with heating speed and throughput. More power enables faster processing of larger material loads.

The Control Systems That Enable Capacity

High capacity is only achievable with precise control. The following systems work together to ensure the furnace can operate reliably at its theoretical limits while maintaining product quality.

Conveying System: Pacing the Process

The conveying system moves material through the furnace. Advanced controls for speed and position are critical, as they determine the "time at temperature"—the duration for which a part is exposed to the peak heat zone.

Adjusting this speed is a primary way to fine-tune the process for different materials and desired outcomes, directly impacting the final throughput.

Power and Temperature Control: Ensuring Precision

Modern furnaces use sophisticated controllers to maintain exact process conditions. A high-end PID (Proportional-Integral-Derivative) controller and step-less power control allow for extremely stable temperatures.

Non-contact temperature monitoring provides real-time data without influencing the material, ensuring the process stays within its specified window. This precision prevents defects and allows the system to run at its maximum efficient speed.

Process Environment: Material Versatility

The ability to operate with different atmospheres—such as inert (e.g., Argon), reducing (e.g., Hydrogen), or oxidizing (e.g., air)—is a crucial aspect of a furnace's capability.

While not a direct measure of physical throughput, this versatility determines the range of materials the furnace can process, fundamentally expanding its operational capacity.

Understanding the Trade-offs

The wide performance ranges in continuous furnaces exist because every design choice involves a trade-off. Recognizing these is key to selecting the right equipment.

Throughput vs. Process Quality

Pushing for maximum throughput by increasing the conveyor speed reduces the time each part spends in the heating zone. For some materials, this can lead to incomplete sintering or other quality defects. The highest possible throughput is often not the optimal setting for quality.

Power vs. Operational Cost

A furnace with 250 kW of installed power offers immense processing capacity but comes with significant energy consumption and higher upfront cost. A lower-power 5.8 kW unit has a much smaller operational footprint but is limited to smaller loads or slower process times.

Size vs. Efficiency

A large cross-section is necessary for large parts but can be inefficient for processing small components. Heating a mostly empty, large-volume furnace wastes a tremendous amount of energy compared to using a smaller furnace appropriately sized for the workload.

Making the Right Choice for Your Goal

Select a furnace by matching its specifications to your primary objective.

- If your primary focus is high-volume production: Prioritize a high maximum throughput (kg/day), a large cross-section, and high installed power (kW) to maximize output.

- If your primary focus is research and development: Value process versatility (multiple atmospheres) and precision controls (PID, step-less power) over raw throughput.

- If your primary focus is processing large, singular parts: The furnace's cross-sectional dimensions (width and height) are your most critical decision criteria.

By analyzing these interconnected specifications, you can move beyond a single capacity number to select a furnace that truly aligns with your specific operational requirements.

Summary Table:

| Specification | Typical Range | Key Influence |

|---|---|---|

| Daily Throughput | 50 - 1000 kg/day | Overall production volume |

| Cross-Section (W x H) | 200-1000 mm x 150-400 mm | Maximum part size |

| Max Temperature | Up to 1700°C | Material compatibility |

| Installed Power | 5.8 kW - 250 kW | Heating speed and load size |

Ready to find the perfect continuous furnace for your lab's throughput and precision needs?

At KINTEK, we specialize in providing high-performance lab equipment, including continuous furnaces tailored for both high-volume production and advanced R&D. Our experts will help you navigate the trade-offs between throughput, power, and control to select a system that maximizes your efficiency and product quality.

Contact our team today for a personalized consultation and discover how KINTEK's solutions can power your next breakthrough.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

People Also Ask

- How is a high-temperature calcination furnace utilized in BZY20 Sol-gel? Achieve Pure Cubic Perovskite Phases

- What is the range of pyrolysis? Master Temperature Control for Optimal Bio-Product Yields

- How do high-temperature reaction furnaces control in-situ MMCs? Master Material Precision and Structural Integrity

- What is the temperature range for pyrolysis? Optimize for Biochar, Bio-oil, or Syngas

- What are the advantages of using a rotary tube furnace for MoVOx catalysts? Elevate Uniformity and Crystallinity