In essence, Chemical Vapor Deposition (CVD) is a process that builds a high-performance, solid thin film on a surface from a chemical reaction in a gas. A volatile chemical precursor is introduced into a vacuum chamber containing the object to be coated. When the chamber is heated, the precursor gas reacts or decomposes on the hot object's surface, depositing a uniform, high-purity coating one layer of atoms at a time.

Chemical Vapor Deposition is not simply spraying a material onto a surface; it is a method of growing a new, high-purity solid layer directly on a substrate through a controlled chemical reaction, valued for its ability to create exceptionally durable and uniform films.

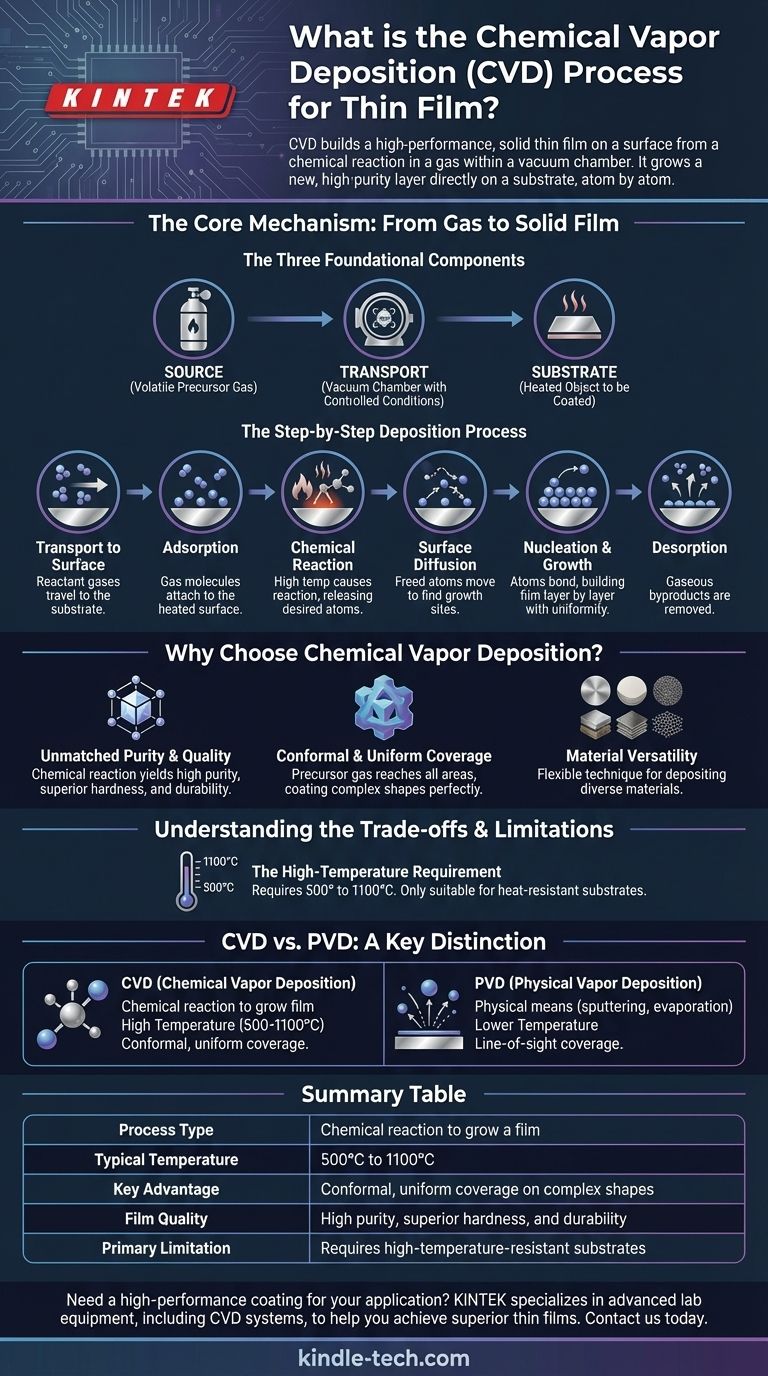

The Core Mechanism: From Gas to Solid Film

To understand how CVD works, it's best to break it down into its foundational components and the precise sequence of events that transform a gas into a solid coating.

The Three Foundational Components

Every vacuum deposition process, including CVD, involves three key elements.

- The Source: In CVD, the source is not a solid block of material but one or more volatile precursor gases. These are chemicals specifically chosen to contain the atoms needed for the final film.

- The Transport: The precursor gases are transported into a sealed vacuum chamber where conditions like pressure and temperature are precisely controlled.

- The Substrate: This is the object or material that will be coated. It is heated to a specific reaction temperature, which is critical for driving the deposition process.

The Step-by-Step Deposition Process

Once the precursor gases enter the chamber and reach the heated substrate, a highly controlled, six-step chain reaction begins.

- Transport to the Surface: The reactant gases travel through the vacuum chamber and arrive at the substrate's surface.

- Adsorption: The gas molecules physically attach, or adsorb, onto the heated surface of the substrate.

- Chemical Reaction: The high temperature of the substrate acts as a catalyst, causing the adsorbed gas molecules to react or decompose, freeing the atoms desired for the film.

- Surface Diffusion: These newly freed atoms move across the surface to find stable locations, known as growth sites.

- Nucleation and Growth: The atoms bond to the growth sites, forming a new solid layer. This process repeats, building up the film layer by layer with exceptional uniformity.

- Desorption: Gaseous byproducts from the chemical reaction detach from the surface and are transported away by the vacuum system.

Why Choose Chemical Vapor Deposition?

CVD is selected over other methods when the quality and properties of the final film are the primary concern. Its unique bottom-up growth process provides distinct advantages.

Unmatched Purity and Quality

Because the film is built from a chemical reaction rather than a melted source material, it can achieve much greater purity. The resulting coatings are known for superior hardness and resistance to damage compared to other methods.

Conformal and Uniform Coverage

The precursor gas can reach every exposed area of the substrate, regardless of its shape. This allows CVD to produce a perfectly even and conformal coating that uniformly covers complex, three-dimensional components.

Material Versatility

CVD is an extremely flexible technique capable of depositing a wide range of materials. This includes everything from simple metallic and ceramic coatings to advanced materials like graphene.

Understanding the Trade-offs and Limitations

Despite its advantages, CVD is not the solution for every application. Its primary limitation is a direct consequence of its core mechanism.

The High-Temperature Requirement

CVD is a hot process. Deposition temperatures typically fall in the range of 500° to 1100°C. This intense heat is necessary to drive the chemical reactions on the substrate's surface.

This requirement means that CVD is only suitable for substrates that can withstand these high temperatures without melting, warping, or degrading.

CVD vs. PVD: A Key Distinction

The main alternative to CVD is Physical Vapor Deposition (PVD). PVD methods like sputtering or evaporation use physical means (e.g., plasma bombardment or melting) to turn a solid source material into a vapor, which then condenses on the substrate. PVD processes often operate at much lower temperatures, making them suitable for plastics and other heat-sensitive materials.

Making the Right Choice for Your Application

Selecting the right deposition technique requires aligning the process capabilities with your primary goal.

- If your primary focus is ultimate hardness, purity, and durability on a heat-resistant substrate: CVD is the superior choice for creating a high-performance, integrated film.

- If your primary focus is coating a temperature-sensitive material like a polymer or certain alloys: You must look to a lower-temperature process like Physical Vapor Deposition (PVD).

- If your primary focus is achieving a perfectly uniform coating on a complex, non-line-of-sight component: CVD's gas-phase nature gives it a distinct advantage in delivering conformal coverage.

Ultimately, understanding the fundamental difference between chemically growing a film (CVD) and physically depositing it (PVD) is the key to making an informed decision.

Summary Table:

| Key Aspect | CVD Process Detail |

|---|---|

| Process Type | Chemical reaction to grow a film |

| Typical Temperature | 500°C to 1100°C |

| Key Advantage | Conformal, uniform coverage on complex shapes |

| Film Quality | High purity, superior hardness, and durability |

| Primary Limitation | Requires high-temperature-resistant substrates |

Need a high-performance coating for your application?

KINTEK specializes in advanced lab equipment, including CVD systems, to help you achieve superior thin films with unmatched purity and durability. Our expertise is tailored to meet the precise needs of laboratory research and development.

Contact us today to discuss how our solutions can enhance your coating process and deliver the material performance you require. Get in touch via our contact form.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- How does chemical Vapour deposition work? A Guide to High-Performance Thin Film Growth

- What temperature does CVD graphene grow at? Unlock the Key to High-Quality Synthesis

- What is the chemical vapor deposition of parylene? A Guide to Conformal Coating

- What are the different types of carbide tool coating? Match the Right Shield to Your Machining Needs

- What is Low Pressure CVD (LPCVD) and what are its advantages? Enhance Film Uniformity & Protect Sensitive Substrates

- What is physical Vapour deposition techniques? A Guide to Sputtering, Evaporation & More

- What are the potential uses of graphene? Unlocking Next-Gen Electronics, Energy, and Materials

- What coating methods are applied for metal cutting tools? PVD vs. CVD for Superior Tool Performance