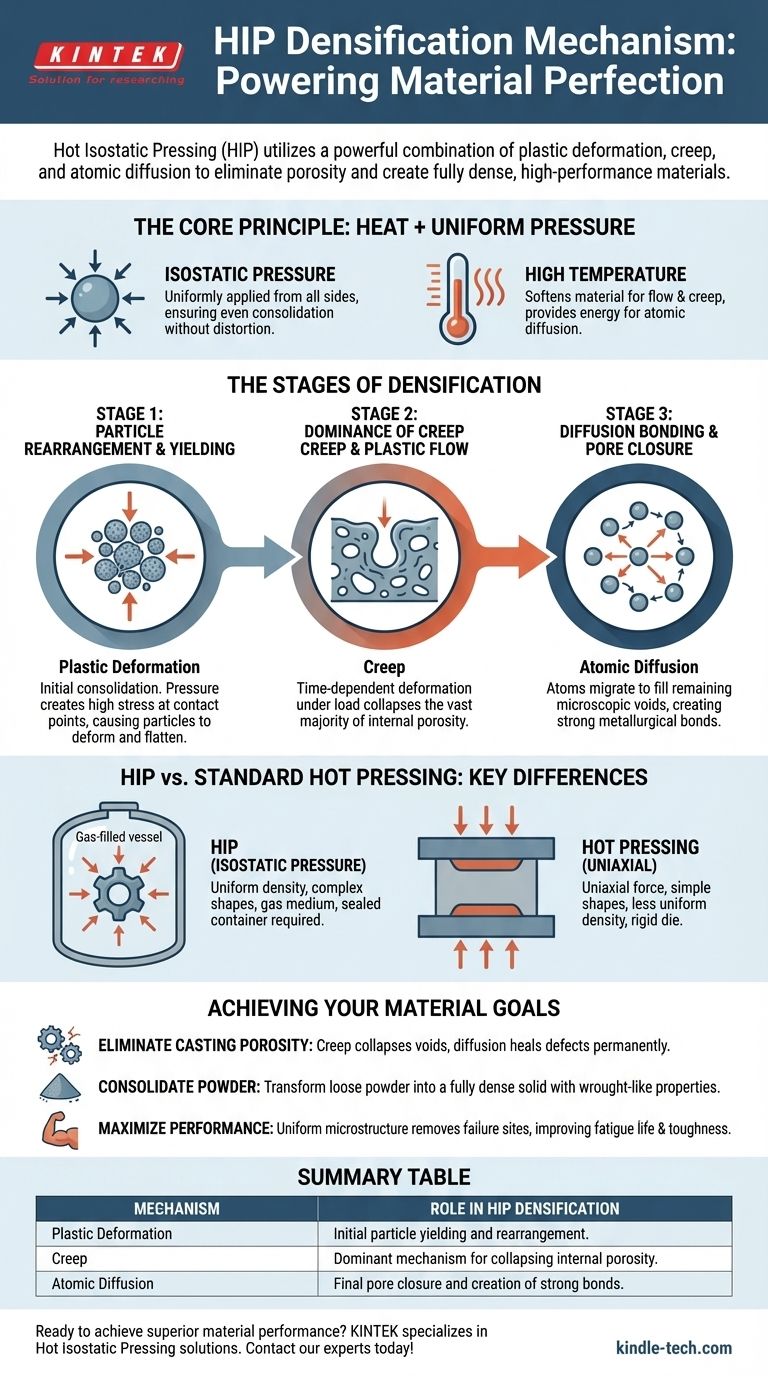

At its core, Hot Isostatic Pressing (HIP) densifies materials through a powerful combination of plastic deformation, creep, and atomic diffusion. Under immense, uniformly applied pressure and high temperature, powder particles or components with internal porosity are forced to yield, flow, and ultimately bond together at a microscopic level, eliminating virtually all internal voids.

The essential mechanism of HIP is not a single action but a controlled, multi-stage process. High pressure first mechanically forces particles together, collapsing large voids, while elevated temperature provides the energy for the material to slowly creep and diffuse, healing the remaining microscopic pores until a fully dense, solid part is achieved.

The Core Principle: Combining Heat and Uniform Pressure

To understand the densification mechanism, we must first appreciate the two fundamental inputs of the HIP process.

What is Hot Isostatic Pressing?

The process involves sealing a component or metal powder inside a container (often called a "can"). This container is then placed into a high-pressure vessel. The vessel is filled with an inert gas, typically Argon, which is heated and pressurized to extreme levels, applying force to the container and the part within it.

The Role of Isostatic Pressure

The term "isostatic" is critical—it means the pressure is applied uniformly from all directions. This is unlike conventional pressing, which applies force along a single axis. This all-sided pressure ensures that the material consolidates evenly without distortion, allowing for the densification of highly complex shapes.

The Function of High Temperature

Pressure alone is not enough. High temperature softens the material, reducing its yield strength and making it susceptible to plastic flow and creep. Crucially, it also provides the thermal energy needed to activate diffusion, the movement of individual atoms, which is the final step in creating perfect metallurgical bonds.

Unpacking the Stages of Densification

The transformation from a porous or powdered state to a fully dense solid occurs in a predictable sequence.

Stage 1: Particle Rearrangement and Initial Yielding

At the start of the cycle, as pressure and temperature ramp up, the initial consolidation begins. Loose powder particles shift and slide into a more tightly packed arrangement. The immense pressure creates extremely high stress at the tiny contact points between particles, causing them to plastically deform and flatten against one another.

Stage 2: Dominance of Creep and Plastic Flow

As the part is held at peak temperature and pressure, the primary densification mechanism takes over. The material's strength is intentionally overcome, causing it to behave like a very slow-moving, viscous fluid. This time-dependent deformation under load is known as creep, and it is responsible for collapsing the vast majority of the internal porosity.

Stage 3: Diffusion Bonding and Final Pore Closure

In the final phase, the material may already be over 98% dense, with only small, isolated, spherical pores remaining. At this point, atomic diffusion becomes the dominant mechanism. Atoms migrate across the surfaces of these tiny voids, gradually "filling" them until they disappear completely. This diffusion process also creates strong, permanent bonds between the original particle boundaries.

Understanding the Trade-offs and Key Differences

It is essential to distinguish HIP from similar-sounding technologies to appreciate its unique capabilities.

Differentiating from Standard Hot Pressing

Standard hot pressing typically uses a rigid die (like a graphite mold) and applies pressure uniaxially—from one or two directions. This limits it to simple shapes and can result in less uniform density.

Isostatic Pressure is the Key Advantage

HIP's use of a gas medium to apply isostatic pressure is its defining feature. This allows for the densification of intricate, near-net-shape parts and ensures a completely uniform microstructure, which is impossible to achieve with directional pressing.

The Requirement for a Sealed System

A key consideration for HIP is that the material must be sealed in a leak-proof container to prevent the high-pressure gas from infiltrating the very pores you are trying to close. For consolidating powders, this means using a specially designed can. For healing defects in a solid casting, the defects must be internal and not connected to the surface.

Making the Right Choice for Your Goal

Understanding the densification mechanism helps you apply the technology effectively.

- If your primary focus is eliminating casting porosity: The key is that the combined pressure and temperature will cause internal voids to collapse via creep, and the internal surfaces will then diffusion-bond together, healing the defect permanently.

- If your primary focus is consolidating powder into a solid part: You must rely on the full sequence of plastic flow, creep, and diffusion to transform loose powder into a fully dense component with properties equivalent to or better than wrought material.

- If your primary focus is achieving maximum material performance: The uniform microstructure and complete removal of internal defects by the HIP process is what eliminates initiation sites for cracks, dramatically improving properties like fatigue life and toughness.

Ultimately, hot isostatic pressing provides a powerful pathway to creating materials that are perfectly dense and internally sound.

Summary Table:

| Mechanism | Role in HIP Densification |

|---|---|

| Plastic Deformation | Initial particle yielding and rearrangement under pressure. |

| Creep | Dominant mechanism for collapsing internal porosity over time. |

| Atomic Diffusion | Final pore closure and creation of strong metallurgical bonds. |

Ready to eliminate porosity and achieve superior material performance?

KINTEK specializes in advanced lab equipment, including Hot Isostatic Pressing solutions, to help you create fully dense, high-integrity components. Our expertise ensures you get the right technology to improve fatigue life, toughness, and material uniformity.

Contact our experts today via our Contact Form to discuss how HIP can benefit your specific laboratory or production needs.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance