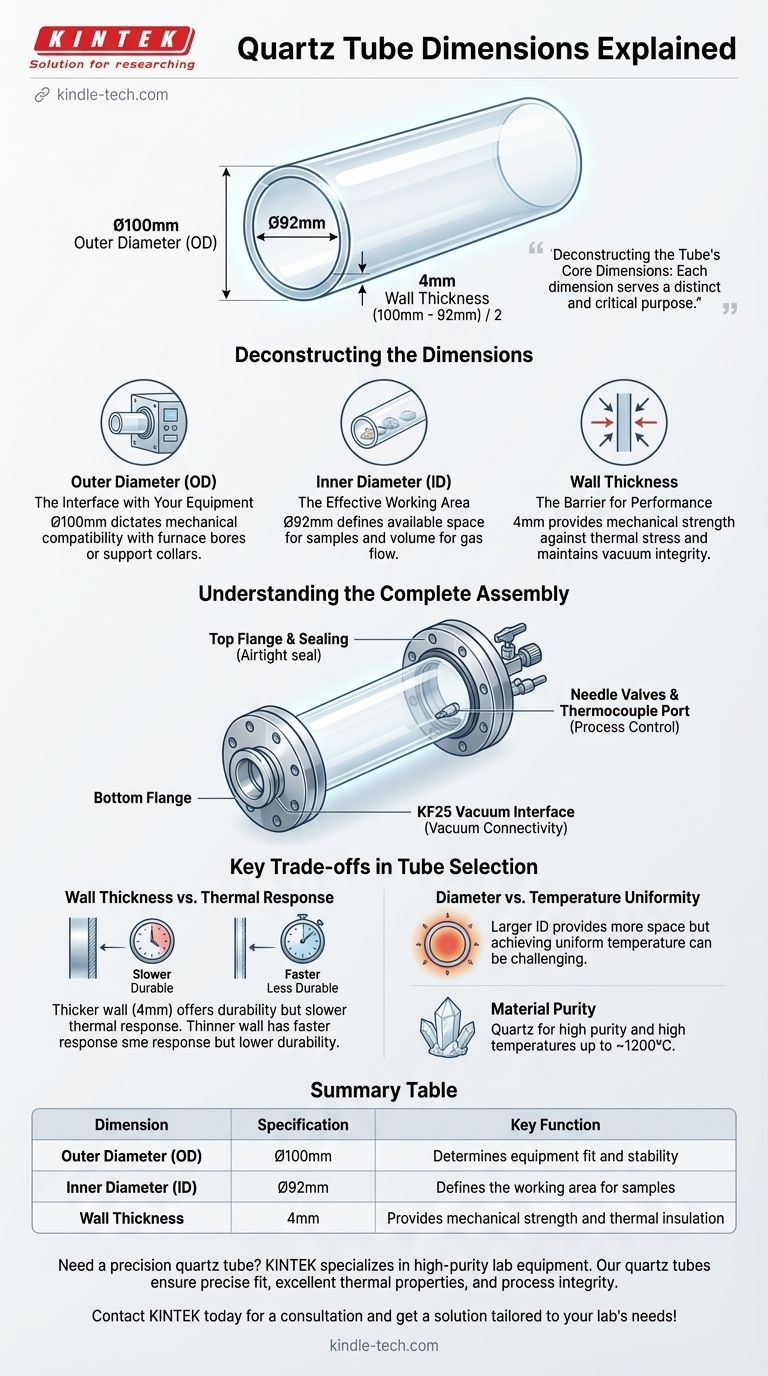

For this specific quartz tube, the outer diameter (OD) is Ø100mm and the inner diameter (ID) is Ø92mm. These two measurements are fundamental to understanding how the tube fits into equipment and how much usable space it provides for your process.

Understanding a quartz tube requires looking beyond a single diameter. The relationship between the outer diameter, inner diameter, and overall length defines its compatibility with your equipment and its capacity for your application.

Deconstructing the Tube's Core Dimensions

A quartz tube is not a simple cylinder; it is a precision component. Each dimension serves a distinct and critical purpose.

Outer Diameter (OD): The Interface with Your Equipment

The outer diameter of Ø100mm is the primary dimension for mechanical compatibility. It dictates whether the tube will fit into the bore of a furnace, a support collar, or a mounting assembly.

This measurement must be precise to ensure a snug, stable fit, which is crucial for uniform heating and operational safety.

Inner Diameter (ID): The Effective Working Area

The inner diameter of Ø92mm defines your "working zone." This is the available space to hold samples, crucibles, or substrates.

It also determines the volume for gas flow in processes like chemical vapor deposition (CVD) or annealing in a controlled atmosphere.

Wall Thickness: The Barrier for Performance

The difference between the OD and ID reveals the wall thickness. In this case, the wall is 4mm thick ((100mm - 92mm) / 2).

This thickness is a critical design parameter. It provides the mechanical strength to withstand thermal stress and maintain vacuum integrity without cracking. A thicker wall offers greater durability and thermal insulation.

Understanding the Complete Assembly

The reference describes more than just a tube; it details a complete process chamber. The flanges and ports are integral to its function.

The Role of Flanges and Sealing

The stainless steel flanges at the top and bottom are designed to create an airtight seal. This is essential for experiments that require a vacuum or a specific, controlled gas atmosphere.

Without these flanges, the tube would simply be an open-ended cylinder, unsuitable for most advanced material processing applications.

Integrated Ports for Process Control

The assembly includes needle valves and a port for a thermocouple. The valves allow for the precise introduction and removal of gases, while the thermocouple port enables direct, accurate temperature measurement inside the tube.

These features transform the tube from a passive container into an active, controllable process environment.

Vacuum Connectivity (KF25 Interface)

The KF25 interface on the bottom flange is a standardized vacuum fitting. Its presence explicitly confirms that this tube assembly is designed to connect to a vacuum pump system for high-vacuum applications.

Key Trade-offs in Tube Selection

Choosing a quartz tube always involves balancing competing factors. Understanding these trade-offs is key to making an informed decision.

Wall Thickness vs. Thermal Response

A thicker wall, like the 4mm wall on this tube, offers excellent durability and is more resistant to thermal shock. However, it also has higher thermal mass, meaning it will heat up and cool down more slowly than a tube with a thinner wall.

Diameter vs. Temperature Uniformity

A larger inner diameter provides more space for samples. However, achieving a perfectly uniform temperature zone across a wider diameter can be more challenging for some furnace systems.

Material Purity vs. Application Demands

Quartz is chosen for its high purity and excellent performance at high temperatures (typically up to ~1200°C). It ensures that the tube itself does not contaminate the process. For even higher temperatures or specific chemical environments, one might need to consider other ceramics like Alumina.

Making the Right Choice for Your Application

Use these guidelines to determine if this tube's specifications align with your goal.

- If your primary focus is sample capacity: The Ø92mm inner diameter is your critical dimension, defining the maximum size of your workload.

- If your primary focus is fitting existing equipment: The Ø100mm outer diameter is non-negotiable and must match your furnace's bore size.

- If your primary focus is a controlled atmosphere or vacuum: The entire assembly, including the steel flanges, seals, and KF25 vacuum port, is just as important as the tube diameter itself.

Ultimately, understanding these interconnected specifications allows you to select a component that is not just a fit, but a solution for your technical objective.

Summary Table:

| Dimension | Specification | Key Function |

|---|---|---|

| Outer Diameter (OD) | Ø100mm | Determines equipment fit and stability |

| Inner Diameter (ID) | Ø92mm | Defines the working area for samples |

| Wall Thickness | 4mm | Provides mechanical strength and thermal insulation |

Need a precision quartz tube for your specific application?

KINTEK specializes in high-purity lab equipment and consumables, serving laboratory needs with reliable, high-performance solutions. Our quartz tubes are designed for precise fit, excellent thermal properties, and process integrity, ensuring your experiments run smoothly and safely.

Let our experts help you select the perfect component for your furnace system and process requirements. Contact KINTEK today for a consultation and get a solution tailored to your lab's needs!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- Why are quartz sealing tubes and argon protection required during annealing of Fe-Mn-Cr alloys? Ensure Alloy Integrity

- Why is a high-temperature tube furnace combined with hydrogen reduction used for nickel powder? Achieve 99.90% Purity

- What role does a tube furnace play in the propane thermal cracking process? Key Functions for Ethylene Production

- How do quartz reactors and furnaces facilitate metal hydride decomposition? Achieve Pure Dehydrogenation and Alloying

- What are the advantages of using a vacuum tube furnace for SiCw/2024Al composites? Ensure Pure, High-Strength Results.

- How does a high-precision tube furnace contribute to the testing of EuOBr catalysts? Ensure Stability & Accuracy

- What is the role of a programmable tube furnace in porous carbon preparation? Master Precision Pyrolysis Control

- What types of atmospheres are possible within a vacuum tube furnace? Master Precise Material Processing Environments