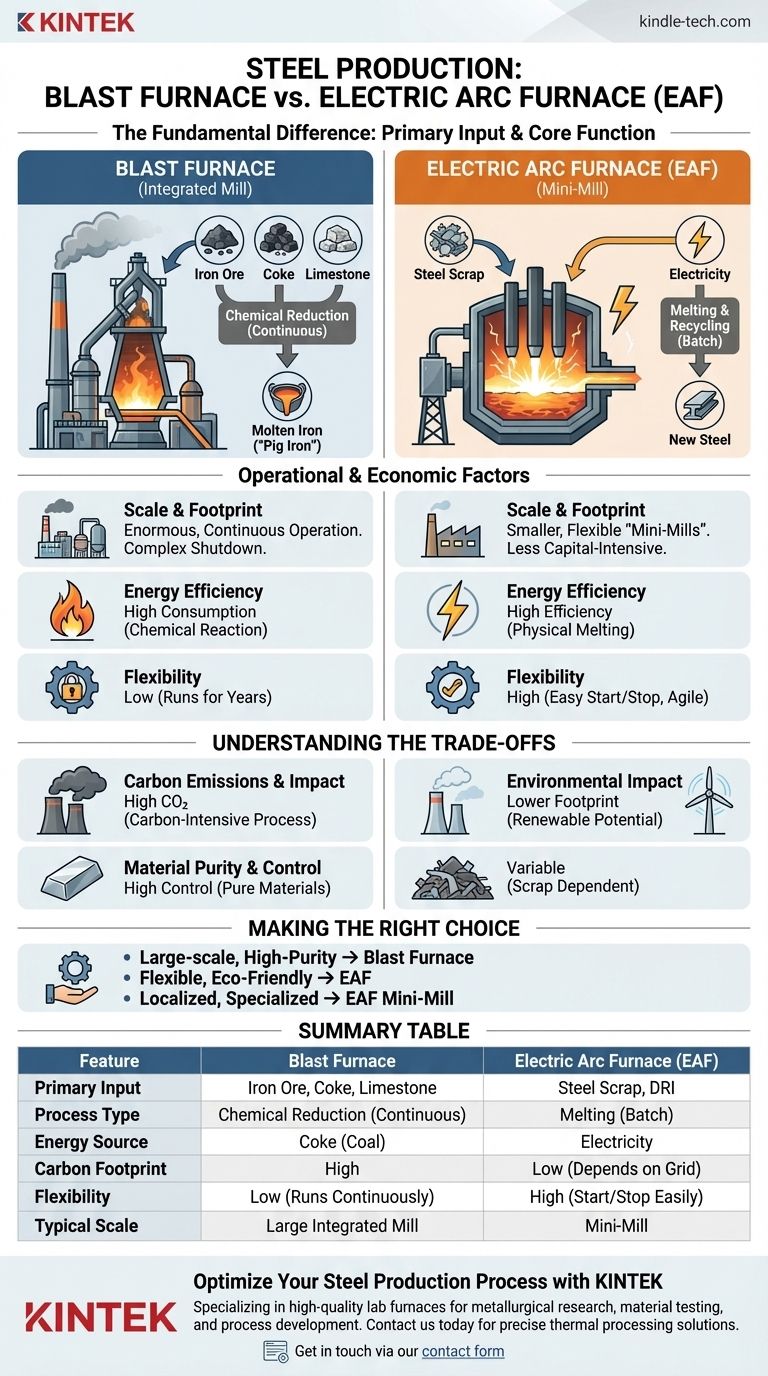

The fundamental difference between a Blast Furnace and an Electric Arc Furnace (EAF) lies in their primary input material and core function. A Blast Furnace uses raw materials like iron ore, coke, and limestone to produce molten iron, which is then converted into steel. In contrast, an EAF primarily uses electricity to melt existing steel scrap, effectively acting as a massive recycling facility.

The choice between these two methods represents a core strategic decision in the steel industry. It dictates the entire supply chain, from raw material sourcing and energy consumption to capital investment and environmental footprint.

The Core Distinction: Raw Material and Process

The most critical difference between the two technologies is what they consume to make steel. This single factor influences nearly every other aspect of their operation.

The Blast Furnace: Creating from Raw Ore

A Blast Furnace is the heart of a traditional, integrated steel mill. Its purpose is to perform a chemical reduction of iron ore into a high-carbon molten iron known as "hot metal" or "pig iron."

This process requires a continuous supply of coke (a high-carbon fuel derived from coal), iron ore, and limestone, which are heated to extreme temperatures. The coke acts as both the fuel source and the reducing agent that strips oxygen from the ore.

The Electric Arc Furnace: Recycling Existing Steel

An EAF operates on a fundamentally different principle. Its primary raw material is steel scrap, although it can also use direct reduced iron (DRI) or hot metal to supplement the charge.

The EAF uses massive graphite electrodes to pass an electric current through the metal, creating an arc. This arc generates intense heat that melts the scrap, which is then refined and cast into new steel. This method is essentially a large-scale recycling process.

Operational and Economic Factors

The difference in raw materials leads to significant operational and economic distinctions.

Scale and Footprint

Blast Furnaces are enormous structures that must run continuously for years and are part of sprawling integrated steel mills. Shutting one down is an incredibly complex and expensive undertaking.

EAFs are far smaller and more flexible. This allows for the creation of "mini-mills," which are less capital-intensive and can be built closer to scrap sources and end-use customers.

Energy Efficiency

The EAF process is significantly more energy-efficient than the Blast Furnace route. An EAF only needs to melt the steel scrap, a physical change.

A Blast Furnace must expend enormous amounts of energy—primarily from burning coke—to drive the chemical reaction that converts iron ore into iron.

Production Flexibility

EAFs can be started and stopped relatively easily, allowing producers to adapt to fluctuations in electricity costs and market demand. This batch-based process offers a level of agility that is impossible for a continuously operating Blast Furnace.

Understanding the Trade-offs

Neither method is universally superior; they serve different market needs and come with distinct advantages and disadvantages.

Carbon Emissions and Environmental Impact

This is a critical modern differentiator. The Blast Furnace process is inherently carbon-intensive because it relies on coke to reduce iron ore, releasing large volumes of CO₂.

The EAF process has a much lower direct carbon footprint. Its environmental impact is primarily tied to the source of its electricity. When powered by renewable energy, an EAF can produce steel with very low emissions.

Material Purity and Control

The integrated route starting with a Blast Furnace offers very precise control over the final steel chemistry because it begins with pure raw materials.

EAF steel quality depends heavily on the quality of the incoming scrap. Residual elements from the scrap (like copper) can be difficult to remove and may be undesirable in certain high-specification steel grades.

Making the Right Choice for Your Goal

Selecting between these technologies depends entirely on the strategic objectives of the steel producer.

- If your primary focus is large-scale production of high-purity steel grades from virgin materials: The traditional Blast Furnace and integrated mill remains the established pathway.

- If your primary focus is flexible, lower-cost production with a significantly smaller environmental footprint: The Electric Arc Furnace is the modern, highly efficient choice.

- If your primary focus is building a localized or specialized steel operation: The EAF-based "mini-mill" is the only economically viable model.

Ultimately, understanding this distinction is crucial to comprehending the economic, logistical, and environmental dynamics of the global steel industry.

Summary Table:

| Feature | Blast Furnace | Electric Arc Furnace (EAF) |

|---|---|---|

| Primary Input | Iron Ore, Coke, Limestone | Steel Scrap, DRI |

| Process Type | Chemical Reduction (Continuous) | Melting (Batch) |

| Energy Source | Coke (Coal) | Electricity |

| Carbon Footprint | High | Low (Depends on Grid) |

| Flexibility | Low (Runs Continuously) | High (Start/Stop Easily) |

| Typical Scale | Large Integrated Mill | Mini-Mill |

Optimize Your Steel Production Process with KINTEK

Whether you are involved in metallurgical research, material testing, or process development, understanding furnace technology is critical. KINTEK specializes in high-quality lab equipment and consumables, including furnaces for analysis, heat treatment, and sample preparation. We serve laboratories and R&D facilities that require precise thermal processing solutions.

Our expertise can help you:

- Select the right furnace for your specific R&D or quality control needs.

- Improve efficiency and accuracy in your thermal processes.

- Access reliable equipment tailored to the steel and metals industry.

Contact us today to discuss how KINTEK's solutions can support your laboratory's goals. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Is torrefaction or pyrolysis for biomass? Choose the Right Thermal Process for Your Biomass Goals

- How much does biomass cost per kWh? Understanding the True Price of Renewable Power

- What is the process of physical vapor deposition? A Guide to High-Performance Thin Film Coating

- How do you convert biomass into energy? A Guide to Thermochemical and Biochemical Methods

- How does a high-precision oven contribute to the post-processing of hydrothermal oxidation products? Ensure Data Purity

- What are the applications of electron beam? A Guide to Precision Energy Delivery

- How does a pyrolysis plant work? Transform Waste into Fuel and Chemicals

- What is reactive magnetron sputtering? A Versatile Method for Thin-Film Synthesis