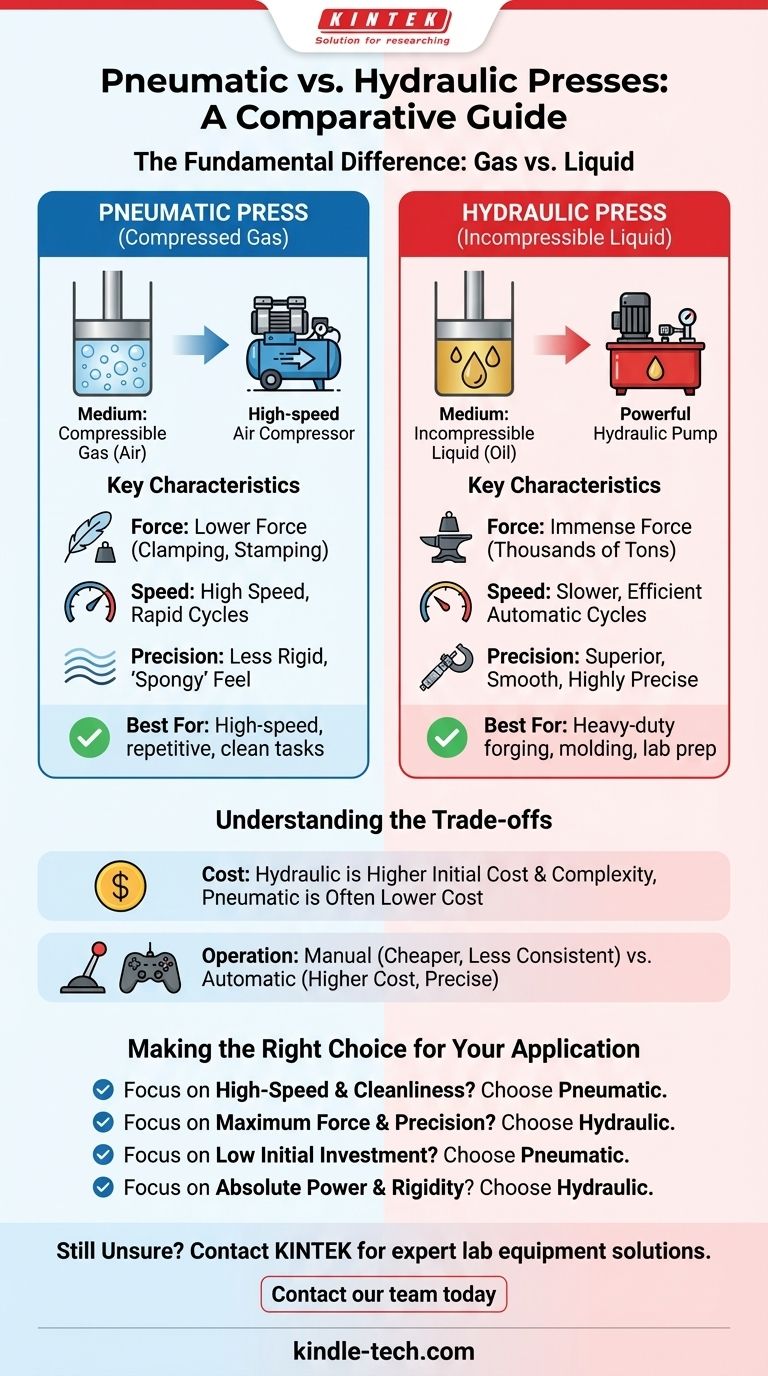

At their core, the difference between a pneumatic and a hydraulic press comes down to the medium used to transmit force. A pneumatic press uses compressed gas (usually air), while a hydraulic press uses a confined liquid (usually oil). This single distinction dictates their capabilities, applications, and operational trade-offs.

The central takeaway is this: Pneumatic presses are best for high-speed, lower-force applications where cleanliness is a priority. Hydraulic presses are unmatched for generating immense force with high precision, making them the standard for heavy-duty industrial and laboratory work.

The Fundamental Difference: Gas vs. Liquid

The choice between compressed air and incompressible liquid is the defining factor that separates these two technologies.

How Pneumatic Presses Work

A pneumatic press operates using an air compressor that supplies pressurized air to a cylinder and piston.

Because air is a compressible gas, the action of a pneumatic press is extremely fast. However, this compressibility can also result in a "spongy" or less rigid application of force, as the gas volume changes under load.

How Hydraulic Presses Work

A hydraulic press uses a pump to force an incompressible liquid, like oil, into a cylinder. This action is governed by Pascal's principle, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid.

This principle allows hydraulic systems to multiply force to enormous levels. The incompressible nature of the liquid also ensures a smooth, rigid, and highly controllable application of force.

Comparing Key Performance Characteristics

Understanding how each press type performs across different metrics is crucial for selecting the right tool.

Force and Power

Hydraulic presses are the undisputed champions of force. They can easily generate thousands of tons of pressure, making them essential for forging, molding, and deep-drawing heavy materials.

Pneumatic presses operate at much lower pressures and are suited for tasks requiring significantly less force, such as clamping, stamping, and light assembly.

Speed and Cycle Rate

Pneumatic systems are generally faster. Air can be compressed and exhausted very quickly, allowing for rapid cycle rates in repetitive tasks.

Hydraulic systems are typically slower due to the higher viscosity of oil and the need to move a larger fluid volume. However, modern automatic hydraulic presses can still achieve efficient cycle times for production environments.

Precision and Control

Hydraulic systems offer superior precision. Because the fluid is incompressible, the movement of the press is perfectly smooth and free of the "springiness" associated with pneumatics.

This makes hydraulic presses, especially automated ones, ideal for laboratory settings or manufacturing processes where exact, repeatable pressure is critical for quality control.

Cleanliness and Maintenance

Pneumatic systems are inherently cleaner. If a leak occurs, it is only air escaping into the environment.

Hydraulic systems, on the other hand, can be messy. A leak in a hose or fitting will result in an oil spill, which can be a safety and environmental hazard. Hydraulic systems also require more maintenance related to fluid filtration and replacement.

Understanding the Trade-offs

Neither system is universally superior; each comes with clear trade-offs tied to its operating principle.

The Cost of Power

The high force of a hydraulic press comes with greater initial cost and complexity. The system requires a hydraulic power unit, which includes a motor, pump, and reservoir, all of which must be robust enough to handle high pressures.

Pneumatic systems are often simpler and more cost-effective to set up, especially if a compressed air source is already available in the facility.

Manual vs. Automatic Operation

Both press types can be configured for manual or automatic control. As noted in laboratory contexts, a manual press uses a hand lever or pump and requires physical effort. It is cheaper but less consistent.

An automatic press uses a powered pump and controller to apply force precisely and repeatedly. This improves workflow efficiency and accuracy but comes at a higher cost.

The Infrastructure Requirement

A pneumatic press is useless without a reliable air compressor capable of supplying the necessary volume and pressure.

Similarly, a hydraulic press requires its dedicated hydraulic power unit. The footprint, noise, and maintenance of this supporting infrastructure must be factored into your decision.

Making the Right Choice for Your Application

Your final decision should be guided by your primary operational goal.

- If your primary focus is high-speed, repetitive tasks like stamping or assembly: A pneumatic press is almost always the more efficient and cost-effective choice.

- If your primary focus is maximum force and precision control for tasks like forging or lab sample preparation: A hydraulic press is the only technology that meets these requirements.

- If your primary focus is a clean operating environment and lower initial investment: A pneumatic system offers a distinct advantage over potentially messy hydraulics.

- If your primary focus is absolute power and rigid force application, regardless of complexity: You must use a hydraulic press.

By understanding the core properties of compressible gas versus incompressible liquid, you can confidently select the press that is perfectly suited to your specific task.

Summary Table:

| Characteristic | Pneumatic Press | Hydraulic Press |

|---|---|---|

| Force Generation | Lower force (ideal for clamping, stamping) | Immense force (thousands of tons) |

| Speed & Cycle Rate | High speed, rapid cycles | Slower, but efficient automatic cycles |

| Precision & Control | Less rigid, "spongy" feel | Superior, smooth, and highly precise |

| Cleanliness | Clean (leaks release air) | Messy (potential for oil spills) |

| Best For | High-speed, repetitive, clean tasks | Heavy-duty forging, molding, lab prep |

Still Unsure Which Press is Right for Your Lab?

Choosing between a pneumatic and hydraulic press is critical for your workflow's efficiency and results. The experts at KINTEK specialize in lab equipment and consumables, and we can help you select the perfect press for your specific application—whether you need the high-speed cleanliness of a pneumatic system or the immense, precise force of a hydraulic press.

Let KINTEK provide the solution that boosts your productivity and ensures precise, repeatable outcomes.

Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual Lab Heat Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy