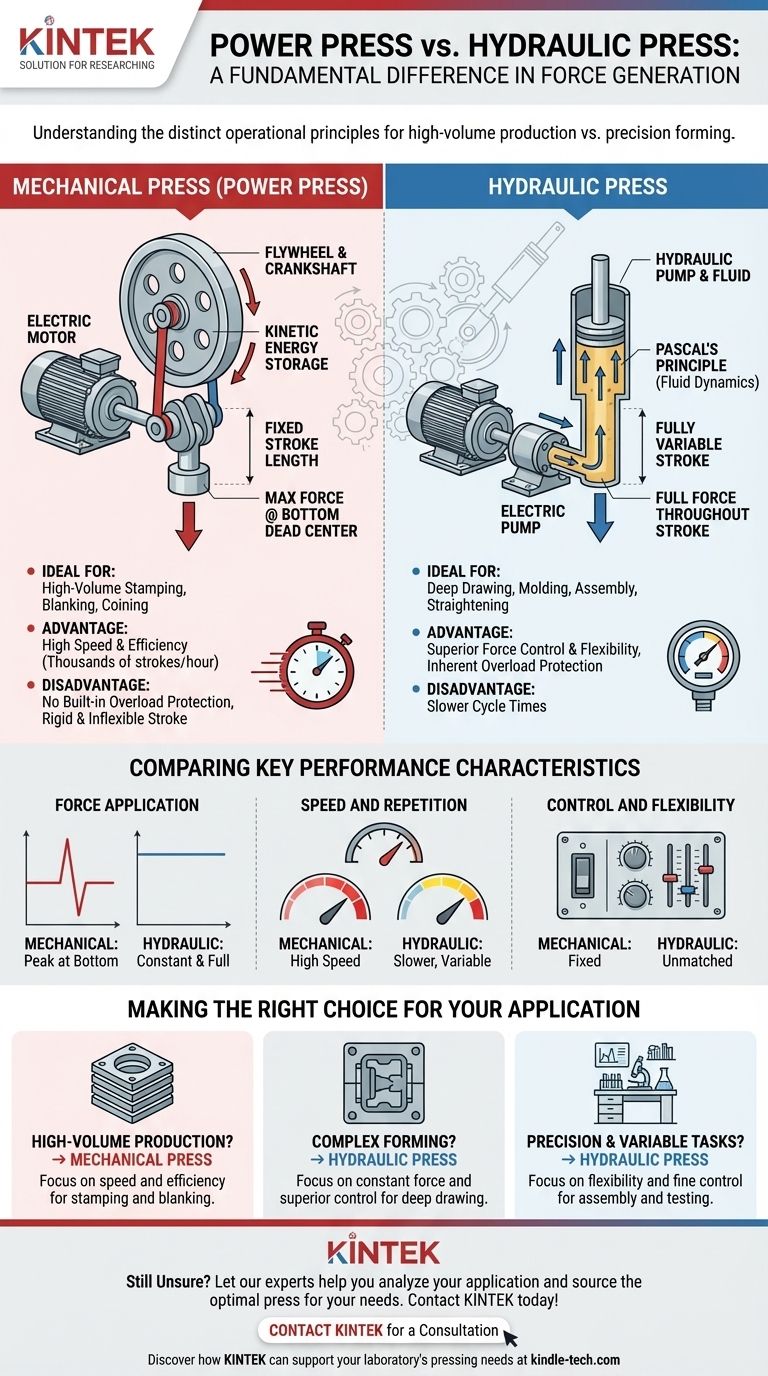

The fundamental difference between a power press and a hydraulic press lies in how they generate force. A power press, more accurately called a mechanical press, uses a flywheel to store and release kinetic energy through a crankshaft to move the ram. In contrast, a hydraulic press uses a pump to pressurize a fluid (typically oil) according to Pascal's principle to exert force.

The choice between these two press types is a classic engineering trade-off. Mechanical presses offer speed and consistency for high-volume production, while hydraulic presses provide superior force control and flexibility for forming and assembly operations.

The Core Mechanism: How They Work

To choose the right tool, you must first understand their distinct operational principles. The method of force generation directly impacts the machine's speed, control, and ideal application.

The Power Press (Mechanical Press)

A mechanical press functions like a car's engine. A large, heavy flywheel is spun by an electric motor to store rotational energy.

When the operator engages the press, a clutch connects the spinning flywheel to a crankshaft. This converts the rotational energy into the vertical, reciprocating motion of the ram.

The stroke length of a mechanical press is fixed and non-adjustable. It delivers its maximum rated tonnage only at the very bottom of its stroke, making it ideal for punching, blanking, and coining operations.

The Hydraulic Press

A hydraulic press operates on a simple principle of fluid dynamics. An electric motor drives a pump, which pushes incompressible oil into a cylinder.

This pressure acts on a piston, forcing the ram downwards. Because the force is generated by fluid pressure, a hydraulic press can deliver its full rated tonnage at any point in its stroke.

This design allows for a fully variable stroke length and precise control over both speed and pressure, which is critical for complex forming tasks. As noted in laboratory settings, automatic hydraulic systems offer highly consistent and accurate pressure application, removing operator variance.

Comparing Key Performance Characteristics

The differences in their core mechanisms create distinct advantages and disadvantages in a production environment.

Force Application

The most critical distinction is how force is delivered. A mechanical press only achieves its maximum force at the bottom dead center of the stroke.

A hydraulic press delivers constant, full force throughout the entire stroke, from the top to the bottom. This makes it superior for applications requiring sustained pressure, like deep drawing or molding.

Speed and Repetition

For high-volume, repetitive tasks like stamping or blanking, the mechanical press is significantly faster. Its quick, cyclical action is optimized for thousands of strokes per hour.

Hydraulic presses are inherently slower due to the time it takes for the pump to move the required volume of oil.

Control and Flexibility

Hydraulic presses offer unmatched control. The operator can precisely adjust the ram's speed, stroke length, and the exact amount of pressure applied. This is essential for delicate assembly, straightening, or forming complex parts.

Mechanical presses are rigid and inflexible by comparison. The stroke is fixed, and pressure is not easily adjusted.

Understanding the Trade-offs

Neither press is universally better; they are simply suited for different tasks. Understanding their limitations is key to avoiding costly mistakes.

The Rigidity of Mechanical Presses

The fixed stroke of a mechanical press can be a liability. If the die setup is incorrect or a workpiece is too thick, the press will attempt to complete its stroke with immense force, which can lead to catastrophic damage to the press or the tooling.

The Speed Limitation of Hydraulic Presses

While flexible, hydraulic presses are not ideal for simple, high-speed punching. Their cycle time is limited by the pump's flow rate and the fluid dynamics of the system, making them less efficient for mass production of simple stamped parts.

Built-in Overload Protection

A major advantage of hydraulic presses is their inherent overload protection. A pressure relief valve prevents the system from exceeding its set tonnage, protecting both the machine and the tooling. A mechanical press has no such built-in protection.

Making the Right Choice for Your Application

Your final decision must be based entirely on the demands of your specific job or workflow.

- If your primary focus is high-volume production (stamping, blanking, coining): The speed and efficiency of a mechanical press make it the clear choice.

- If your primary focus is forming complex shapes (deep drawing, molding): The constant force and superior control of a hydraulic press are non-negotiable.

- If your primary focus is precision and variable tasks (assembly, lab testing, straightening): A hydraulic press provides the flexibility and fine control needed for accurate, repeatable results.

Ultimately, selecting the correct press is about matching the machine's fundamental method of generating force to the specific requirements of your application.

Summary Table:

| Feature | Mechanical Press | Hydraulic Press |

|---|---|---|

| Force Generation | Flywheel & Crankshaft (Kinetic Energy) | Hydraulic Pump & Fluid (Pascal's Principle) |

| Force Delivery | Maximum force only at bottom of stroke | Full, constant force throughout the entire stroke |

| Speed | High (thousands of strokes/hour) | Slower cycle times |

| Control & Flexibility | Fixed stroke; limited pressure adjustment | Fully variable stroke, speed, and pressure control |

| Ideal For | High-volume stamping, blanking, coining | Deep drawing, molding, lab testing, assembly, straightening |

| Overload Protection | No built-in protection | Inherent (pressure relief valve) |

Still Unsure Which Press is Right for Your Lab or Production Needs?

Choosing between a mechanical and hydraulic press is critical for the efficiency and success of your operations. At KINTEK, we specialize in providing the right lab equipment and consumables to meet your specific challenges.

Let our experts help you:

- Analyze your application to determine the optimal press type for your materials and processes.

- Source reliable equipment that ensures precision, safety, and repeatability in your work.

- Enhance your laboratory's capabilities with equipment tailored for forming, testing, and assembly tasks.

Don't leave your project's success to chance. Contact our team today for a personalized consultation and discover how KINTEK can support your laboratory's pressing needs.

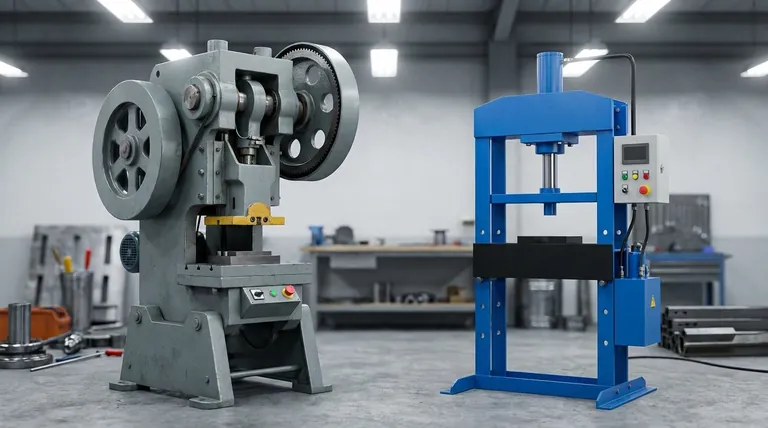

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy