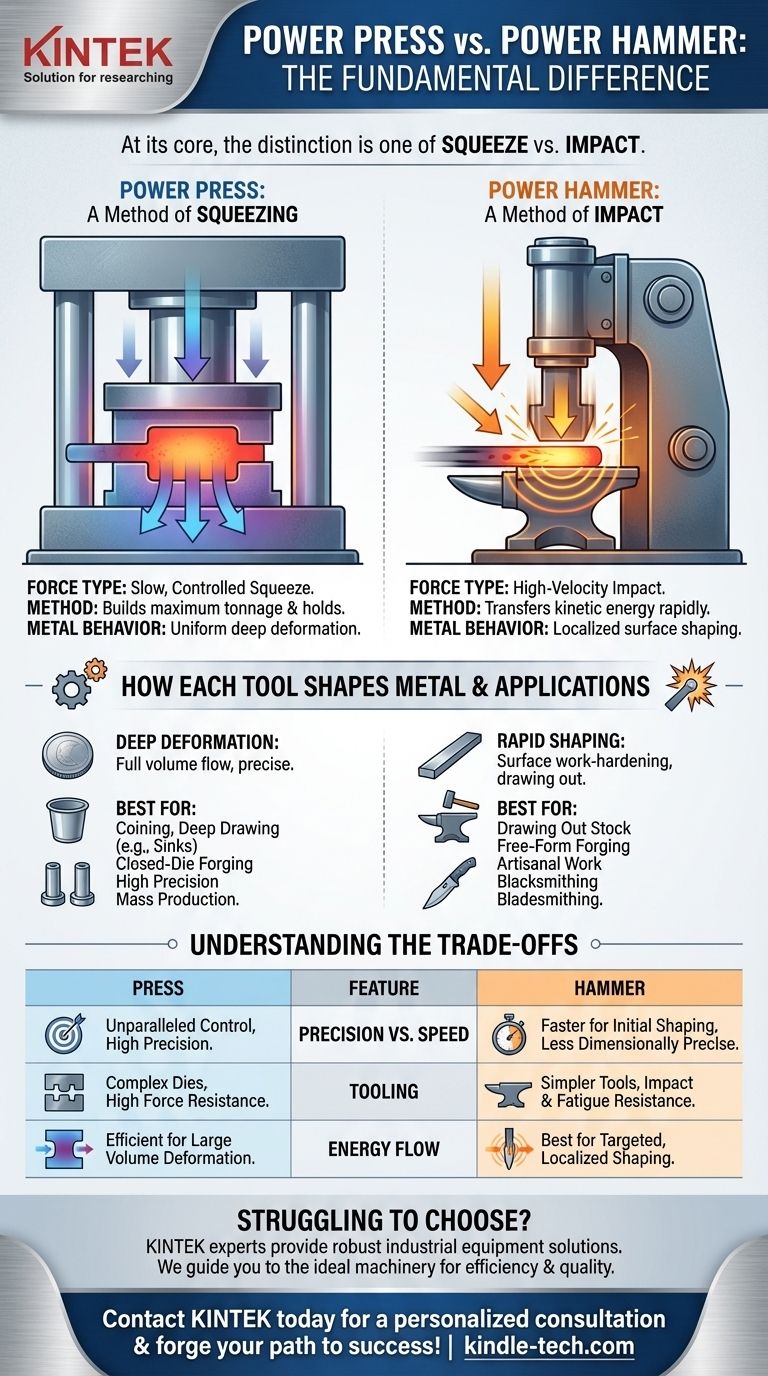

At its core, the distinction is one of squeeze versus impact. A power press uses a slow, controlled, and immense squeezing force to deform metal, while a power hammer uses high-velocity, repetitive strikes to shape material through impact. The method of force application fundamentally changes how the metal behaves and dictates the ideal use for each machine.

The fundamental choice between a press and a hammer is a choice of process. A press is chosen for controlled, uniform deformation through the entire workpiece, while a hammer is selected for rapid, often surface-level shaping and drawing out material.

The Mechanics of Force Application

To understand when to use each machine, you must first grasp how they deliver energy to the workpiece. Their methods are fundamentally different and produce distinct results in the metal's structure.

The Power Press: A Method of Squeezing

A power press applies force gradually and continuously throughout its stroke. Whether mechanical or hydraulic, its purpose is to build to a maximum force (rated in tonnage) and hold it, squeezing the metal into a new shape within a die.

Think of it like a massive, automated nutcracker. The force is predictable and penetrates deep into the material, causing the entire volume of the metal to flow and conform to the die's shape.

The Power Hammer: A Method of Impact

A power hammer operates on the principle of kinetic energy. It rapidly accelerates a heavy ram or tup and brings it to a sudden stop against the workpiece. This transfers a massive amount of energy in a very short duration.

This action is analogous to a blacksmith's arm, but with far greater power and speed. The force is dynamic and concentrated at the point of impact, making it ideal for moving metal quickly.

How Each Tool Shapes Metal

The difference between a slow squeeze and a rapid impact has profound effects on the metal's internal grain structure. This determines the types of jobs for which each machine is best suited.

Deep Deformation in a Press

The sustained pressure from a press gives the metal's crystalline structure time to move and realign. This "plastic deformation" occurs uniformly throughout the material's thickness.

This makes presses the superior choice for operations requiring high precision and detail, such as coining, deep drawing (like forming a kitchen sink), and closed-die forging where the final shape is complex.

Rapid Shaping from a Hammer

The sharp blows from a hammer create a different effect. The impact primarily deforms the metal near the surface, and the energy dissipates as it travels deeper. This is highly effective for drawing out stock (making it longer and thinner).

This process also work-hardens the surface of the metal. Power hammers excel in open-die or free-form forging where an operator manually manipulates the workpiece between blows, making them a staple for blacksmiths and bladesmiths.

Understanding the Trade-offs

Choosing the wrong machine for a task leads to inefficiency, poor quality, or outright failure. The decision requires understanding their inherent limitations.

Precision vs. Speed

A press offers unparalleled control over the final dimensions. Its stroke is fixed and its force is measurable, making it perfect for mass production of identical parts.

A hammer is significantly faster for initial shaping and rough forming. Its repetitive blows can move metal much more quickly than the single stroke of a press, but with less dimensional precision.

Tooling and Die Complexity

Press tooling must be engineered to withstand immense, sustained force across its entire surface. Dies are often complex and represent a significant investment.

Hammer tooling is generally simpler, often consisting of flat or specially shaped dies (known as anvils and pallets). These tools must be incredibly tough to resist the shock and fatigue of repeated impacts.

Energy and Material Flow

A press is more energy-efficient for deforming the entire volume of a large workpiece because the force is applied once and works through the material.

A hammer's energy is best for targeted, localized shaping. It is less effective at uniformly shaping a very thick piece of stock, as the impact's energy may not penetrate all the way through.

Making the Right Choice for Your Goal

Your specific objective dictates which machine is the correct tool for the job.

- If your primary focus is high-volume, repeatable precision: Choose a power press for its unparalleled control in operations like coining, stamping, and closed-die forging.

- If your primary focus is artisanal or custom forging: Choose a power hammer for its speed and versatility in drawing out material and free-form shaping of unique parts.

- If your primary focus is breaking down large ingots or pre-forming billets: A large forging press provides the deep, uniform deformation needed, while a hammer can be used for initial shaping and cogging.

Ultimately, selecting the right machine comes from understanding that you are choosing not just a tool, but a specific method of manipulating metal.

Summary Table:

| Feature | Power Press | Power Hammer |

|---|---|---|

| Force Type | Slow, controlled squeeze | High-velocity impact |

| Primary Use | Precision, deep deformation (e.g., coining, deep drawing) | Rapid, surface-level shaping (e.g., drawing out, free-form forging) |

| Best For | High-volume, repeatable parts | Artisanal, custom forging |

| Metal Flow | Uniform throughout the workpiece | Localized at the point of impact |

Struggling to choose the right equipment for your metal forging or shaping needs? The experts at KINTEK are here to help. We specialize in providing robust lab and industrial equipment, including solutions for material testing and preparation. Whether your project demands the precision of a press or the versatility of a hammer, we can guide you to the ideal machinery for your specific application, ensuring efficiency and quality in your results.

Contact KINTEK today for a personalized consultation and let us help you forge a path to success!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Lab Heat Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples