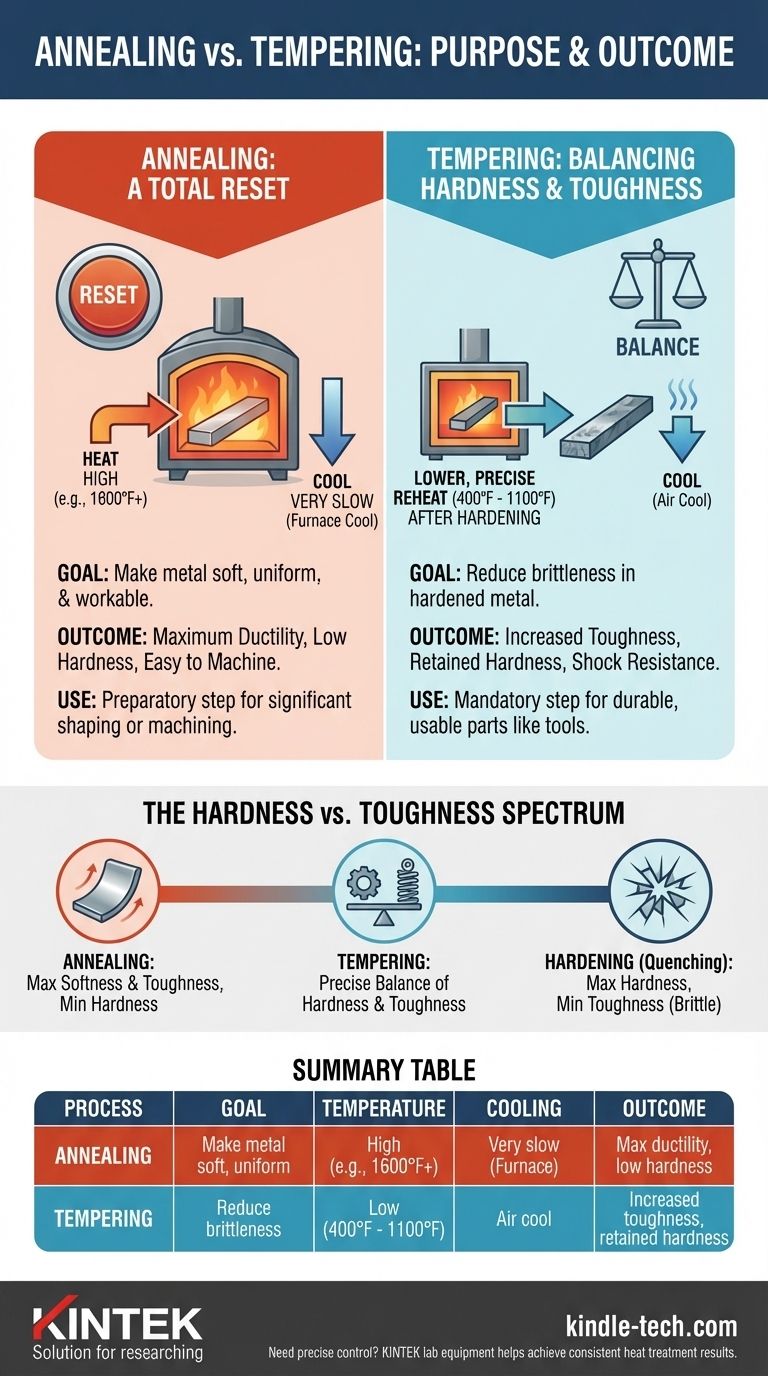

At its core, the difference is one of purpose and outcome. Annealing is a heat treatment process designed to make a metal as soft, uniform, and workable as possible by heating it to a high temperature and cooling it very slowly. Tempering, in contrast, is a lower-temperature process performed after a metal has already been hardened to reduce its brittleness and increase its toughness.

While both are heat treatment processes, they serve opposite functions. Annealing is a "reset button" that maximizes softness and relieves internal stress. Tempering is a fine-tuning step that trades a small amount of hardness for a significant increase in toughness in an already hardened part.

The Goal of Annealing: A Total Reset

Annealing is used to put a metal into its softest, most stable, and most uniform state. It is a preparatory step, not a final finishing process for parts that require hardness.

The Process: Heat High and Cool Slow

To anneal a metal like steel, it is heated well above its critical temperature—often to 1600°F (870°C) or higher. It is held at this temperature long enough for its internal crystalline structure (grains) to reform completely.

The most critical step is the extremely slow cooling. The metal is often left to cool down over many hours inside the insulating furnace after it has been turned off. This slow cool allows large, uniform, and stress-free grains to form.

The Outcome: Maximum Ductility and Machinability

An annealed part has minimal internal stress, low hardness, and high ductility. This makes the metal very easy to bend, form, or machine. It erases the effects of previous work hardening or improper heat treatments.

When to Use Annealing

You anneal a workpiece when you need to perform significant shaping or machining. It is also used to prepare a piece of steel with an unknown or inconsistent history for a new, controlled hardening and tempering cycle.

The Goal of Tempering: Balancing Hardness and Toughness

Tempering is never a standalone process. It is the mandatory second step that always follows a hardening procedure (heating and then rapidly quenching in oil or water).

The Prerequisite: Hardening

Hardening makes steel extremely hard but also dangerously brittle, like glass. A hardened but untempered blade or tool would likely shatter upon its first use. Tempering corrects this brittleness.

The Process: A Lower, Precise Reheat

The hardened part is cleaned and then gently reheated to a much lower, very specific temperature—typically between 400°F and 1100°F (205°C and 595°C). This temperature is always below the metal's critical point.

The part is held at this temperature for a set time to allow some of the trapped stress and brittle internal structures to relax and reform. It is then typically allowed to cool in still air. The exact temperature used determines the final balance of hardness and toughness.

The Outcome: Reduced Brittleness, Retained Hardness

Tempering makes the steel significantly tougher and more resistant to shock and impact. While it does slightly reduce the peak hardness achieved during quenching, the trade-off is essential for creating a durable, usable part like a knife, axe, or spring.

Understanding the Trade-offs

Choosing between these processes is not a matter of preference; it is dictated by the desired mechanical properties of the final part.

The Hardness vs. Toughness Spectrum

Think of a material's properties on a spectrum. Annealing pushes the metal all the way to one end: maximum softness and toughness, but minimum hardness. Hardening (quenching) pushes it to the opposite end: maximum hardness, but minimum toughness (maximum brittleness).

Tempering is the art of precisely navigating the space between those two extremes to find the ideal balance for a specific application.

A Common Point of Confusion: Stress Relief

Both processes relieve internal stress, but for different reasons. Annealing performs a full-scale stress relief by completely recrystallizing the metal's grain structure, erasing its history.

Tempering performs a more limited stress relief specifically to reduce the extreme brittleness caused by hardening, without sacrificing too much of that newfound hardness.

Making the Right Choice for Your Material

Your choice is determined entirely by what you need the metal to do next.

- If your primary focus is to make metal as soft as possible for machining or forming: Your only choice is to perform a full anneal.

- If your primary focus is to make a hardened part usable and resistant to shattering: You must temper the part to increase its toughness.

- If you are starting with a piece of scrap steel with an unknown history: Anneal it first to create a uniform, predictable baseline before you begin any hardening and tempering cycle.

Understanding this distinction allows you to precisely control a material's final properties, moving from guesswork to intentional engineering.

Summary Table:

| Process | Goal | Temperature | Cooling | Outcome |

|---|---|---|---|---|

| Annealing | Make metal soft, uniform, and workable | High (e.g., 1600°F+) | Very slow (furnace cool) | Maximum ductility, low hardness, easy to machine |

| Tempering | Reduce brittleness in hardened metal | Low (400°F - 1100°F) | Air cool | Increased toughness, retained hardness, shock resistance |

Need precise control over your material's properties? KINTEK specializes in lab equipment and consumables for all your heat treatment and materials testing needs. Whether you're annealing for machinability or tempering for toughness, our solutions help you achieve consistent, reliable results. Contact our experts today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vertical Laboratory Tube Furnace

People Also Ask

- How does a vacuum affect heat transfer? Master Precise Thermal Control in Your Lab

- Why is an industrial-grade drying oven utilized for pre-drying peanut shells? Ensure High-Accuracy Pyrolysis Results

- What is the function of a vacuum arc melting furnace? Master Homogeneity for Fe-Co Metallic Glasses

- How does a vacuum heat treat furnace work? Achieve Pristine, Oxide-Free Metal Parts

- How does a vacuum furnace aid titanium diffusion bonding? Unlock High-Performance Multilayer Laminate Manufacturing

- Why is thin-film deposition typically performed in vacuum? Ensure High Purity and Precise Control

- How is vacuum brazing done? Achieve High-Strength, Flux-Free Metal Joining

- What are the disadvantages of heat treatment? Managing the Risks of Distortion and Cost