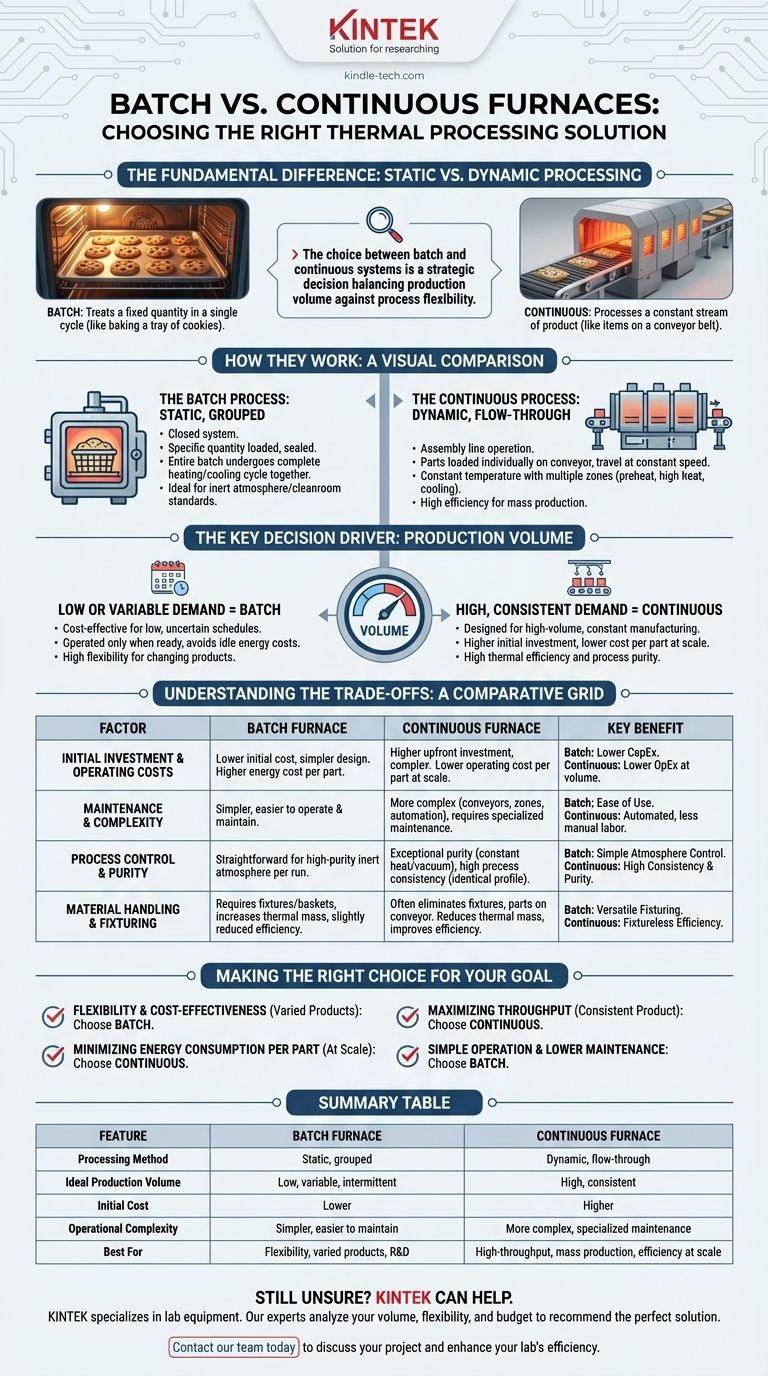

The fundamental difference between batch and continuous furnaces lies in how they process materials. A batch furnace treats a stationary, fixed quantity of product in a single cycle, similar to baking a tray of cookies. In contrast, a continuous furnace processes a constant stream of product that moves through the heat chamber, like items on a conveyor belt.

The choice between batch and continuous systems is not merely operational; it's a strategic decision balancing production volume against process flexibility. Batch furnaces excel in low-volume, high-variety environments, while continuous furnaces are built for high-throughput, standardized production.

How They Work: A Fundamental Comparison

Understanding the operational mechanics of each furnace type reveals their inherent strengths and weaknesses. The core distinction is static versus dynamic processing.

The Batch Process: Static, Grouped Processing

A batch furnace is a closed system where a specific quantity of material, often held in baskets or racks, is loaded into the chamber.

The chamber is sealed, and the entire batch undergoes a complete heating and cooling cycle together. Once the process is finished, the furnace is opened and the entire batch is removed.

This design makes batch furnaces ideal for processes requiring an inert atmosphere or cleanroom standards, as the system is fully sealed during operation.

The Continuous Process: Dynamic, Flow-Through Processing

A continuous furnace operates more like an assembly line. Parts are loaded individually or in small groups onto a conveyor and travel through the furnace at a constant speed.

The furnace maintains a constant temperature, often with multiple zones for preheating, high heat, and cooling. Each part is heated individually as it passes through.

This flow-through design eliminates the need for large racks and the time spent loading and unloading discrete batches, making it highly efficient for mass production.

The Key Decision Driver: Production Volume

More than any other factor, your required production volume will dictate the correct furnace choice. This is the primary axis on which the decision pivots.

When to Choose Batch: Low or Variable Demand

Batch furnaces are the cost-effective solution for low, uncertain, or intermittent production schedules.

Because they only need to be operated when a batch is ready, they avoid the energy costs of keeping a large system at temperature during idle periods. Their inherent flexibility allows for easy changes in temperature profiles and cycle times between different product runs.

When to Choose Continuous: High, Consistent Demand

Continuous furnaces are designed for high-volume manufacturing where production is constant. The initial investment is higher, but the cost per part drops significantly at scale.

By keeping the heat chamber constantly hot and under vacuum (in a vacuum furnace context), they achieve high thermal efficiency and process purity. The productivity of a continuous system for processes like annealing, brazing, or sintering is unmatched when volume is high.

Understanding the Trade-offs

Beyond volume, you must weigh the competing factors of cost, complexity, and process control.

Initial Investment and Operating Costs

Batch furnaces have a lower initial cost and are generally less expensive to maintain over their lifetime due to their simpler design.

Continuous furnaces are more complex and carry a significantly higher upfront investment. However, their superior energy efficiency at scale can lead to a lower operating cost per part in a high-throughput environment.

Maintenance and Operational Complexity

The simpler mechanical nature of a batch furnace makes it easier to operate and maintain.

A continuous furnace, with its conveyor systems, multiple heat zones, and automated loading/unloading mechanisms, is inherently more complex and requires more frequent and specialized maintenance.

Process Control and Atmosphere Purity

While both can achieve excellent results, they do so differently. A sealed batch furnace provides a straightforward way to maintain a high-purity inert atmosphere for an entire run.

A continuous vacuum furnace can also achieve exceptional purity by keeping its heat chambers permanently hot and under vacuum, preventing contamination between cycles. The constant travel ensures every part sees the exact same temperature profile, leading to high process consistency.

Material Handling and Fixturing

Batch processing almost always requires fixtures, baskets, or racks to hold parts. This adds to the thermal mass that must be heated and cooled, slightly reducing energy efficiency.

Continuous furnaces often eliminate the need for fixtures, as parts travel directly on the conveyor. This reduces the total thermal mass, improving energy efficiency and often shortening cooling times.

Making the Right Choice for Your Goal

Select the furnace technology that aligns directly with your primary business and production objectives.

- If your primary focus is flexibility and cost-effectiveness for varied products: A batch furnace offers the adaptability and lower initial investment needed for diverse or low-volume work.

- If your primary focus is maximizing throughput for a consistent product: A continuous furnace provides the unparalleled efficiency and low cost-per-part required for mass production.

- If your primary focus is minimizing energy consumption per part at scale: A continuous furnace is more efficient, as it avoids repeatedly heating large fixtures and the furnace chamber itself from a cold start.

- If your primary focus is simple operation and lower maintenance costs: The less complex design of a batch furnace makes it the more manageable and less expensive option to run and maintain.

Ultimately, understanding this core distinction between static batch processing and dynamic continuous flow empowers you to invest in the right tool for your specific production strategy.

Summary Table:

| Feature | Batch Furnace | Continuous Furnace |

|---|---|---|

| Processing Method | Static, grouped processing | Dynamic, flow-through processing |

| Ideal Production Volume | Low, variable, or intermittent | High, consistent |

| Initial Cost | Lower | Higher |

| Operational Complexity | Simpler, easier to maintain | More complex, requires specialized maintenance |

| Best For | Flexibility, varied products, R&D | High-throughput, mass production, efficiency at scale |

Still unsure which furnace is right for your lab's production goals?

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you analyze your specific requirements for volume, flexibility, and budget to recommend the perfect batch or continuous furnace solution.

Contact our team today to discuss your project and discover how KINTEK can enhance your lab's efficiency and productivity with the right thermal processing equipment.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing