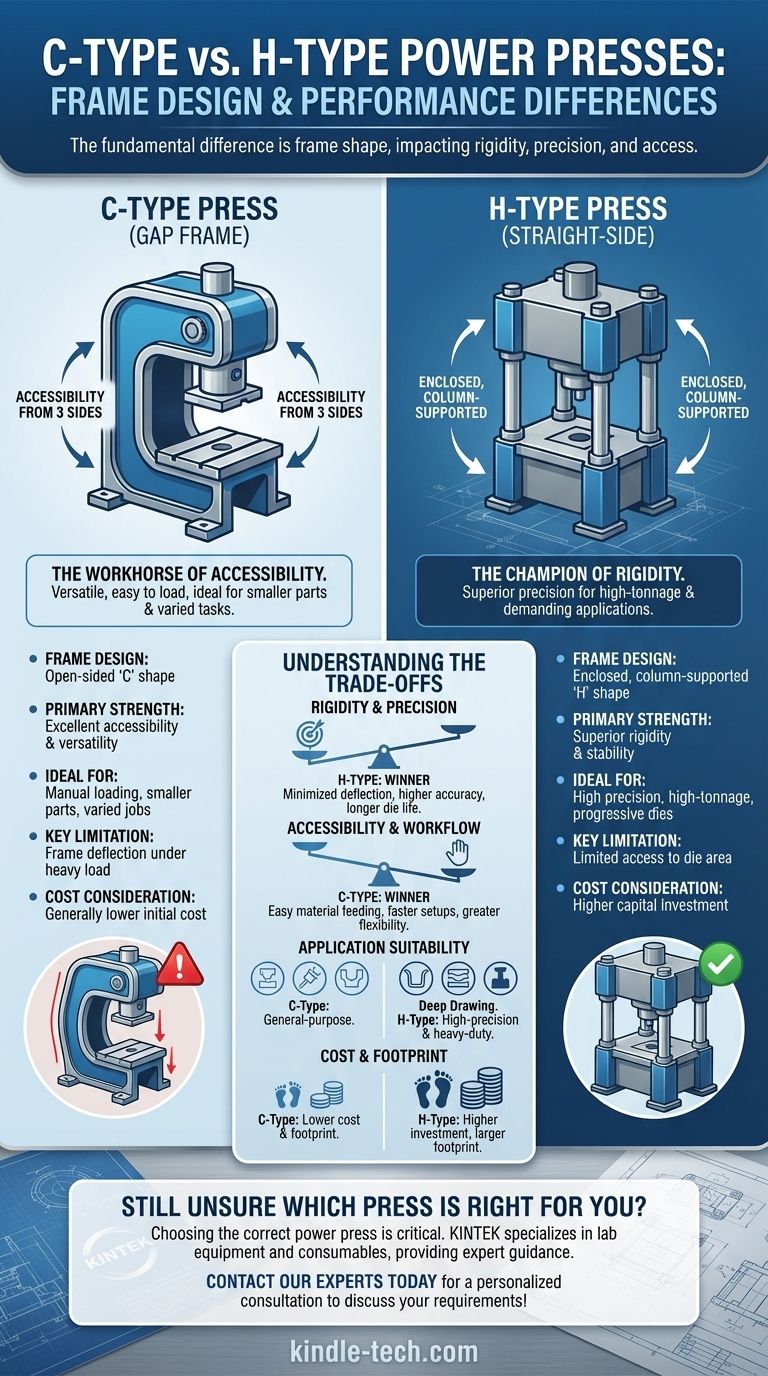

The fundamental difference between a C-type and H-type power press lies in the shape and construction of their frames. A C-type press, also known as a gap frame press, features an open-sided frame shaped like the letter "C," providing excellent access from three sides. In contrast, an H-type press, often called a straight-side press, has a fully enclosed, column-supported frame that offers superior rigidity. This single design distinction dictates the machine's performance, precision, and ideal applications.

The choice between a C-type and H-type press is a direct trade-off between accessibility and versatility (C-type) versus structural rigidity and precision (H-type). Understanding the demands of your specific operation is key to making the correct decision.

The C-Type Press: The Workhorse of Accessibility

A C-type press is one of the most common designs found in fabrication shops due to its versatility and ease of use. Its defining characteristic is its C-shaped frame.

The Open Frame Design

The frame is a single solid casting or fabrication that leaves the front, left, and right sides of the die area open. This provides unparalleled access for operators and automation systems.

Core Advantage: Unmatched Access

This open design is ideal for manually loading and unloading parts, accommodating unconventional part shapes, or integrating coil feeders and other automation from the side of the machine. Die changes are often faster and simpler.

The Inherent Limitation: Frame Deflection

Under heavy load, the open "gap" of the C-frame has a tendency to flex or "yawn." This slight opening of the gap, known as frame deflection, can impact the final accuracy of the part and can lead to uneven wear on the tooling over time.

The H-Type Press: The Champion of Rigidity

An H-type, or straight-side press, is engineered for demanding applications where precision is paramount. Its design directly addresses the limitations of the C-frame.

The Closed Frame Design

The H-type press uses a full frame with two or four massive steel columns that connect the machine bed to the crown. This creates a fully enclosed, box-like structure that is inherently more rigid and stable.

Core Advantage: Superior Precision

By distributing the pressing force evenly across the frame columns, an H-type press minimizes deflection. This structural integrity ensures consistent die alignment, which results in higher part accuracy, better quality, and significantly longer die life.

The Practical Consideration: Limited Access

The columns that provide rigidity also limit access to the die area. Material and tooling can typically only be loaded from the front and back of the press, which can complicate certain workflows and automation setups.

Understanding the Trade-offs: A Direct Comparison

Choosing between these two designs involves weighing their inherent strengths and weaknesses against the needs of your manufacturing process.

Rigidity and Precision

The H-type press is the clear winner. Its closed frame is built to resist the angular deflection that C-type frames experience, making it the standard for high-precision stamping, deep drawing, and progressive die operations.

Accessibility and Workflow

The C-type press offers superior flexibility. Its open sides allow for easy material feeding from multiple directions and faster setup for a wider variety of jobs, making it an excellent general-purpose machine.

Application Suitability

C-type presses excel at blanking, piercing, and forming operations on smaller parts where extreme precision is not the primary concern. H-type presses are necessary for high-tonnage applications, large-bed operations, and any process requiring tight tolerances.

Cost and Footprint

For a given tonnage, C-type presses are generally less expensive and have a smaller footprint. The robust construction and additional material required for an H-type press represent a more significant capital investment.

Making the Right Choice for Your Application

Your final decision should be guided by the specific demands of your parts and production goals.

- If your primary focus is versatility and frequent job changes: A C-type press is the ideal choice for its unmatched accessibility and lower initial cost.

- If your primary focus is high-volume production with maximum precision: An H-type press provides the rigidity needed to maintain part quality and protect your investment in expensive tooling.

- If your operation involves progressive dies or deep drawing: The superior stability and minimal deflection of an H-type press are non-negotiable.

Ultimately, understanding this core difference in frame design empowers you to select not just a machine, but the right foundation for a reliable and efficient manufacturing process.

Summary Table:

| Feature | C-Type Press (Gap Frame) | H-Type Press (Straight-Side) |

|---|---|---|

| Frame Design | Open-sided 'C' shape | Enclosed, column-supported 'H' shape |

| Primary Strength | Excellent accessibility from 3 sides | Superior rigidity and stability |

| Ideal For | Versatility, manual loading, smaller parts | High precision, high-tonnage, progressive dies |

| Key Limitation | Frame deflection under heavy load | Limited access to die area |

| Cost Consideration | Generally lower initial cost | Higher capital investment |

Still Unsure Which Press is Right for Your Lab or Production Line?

Choosing the correct power press is critical for the accuracy and efficiency of your manufacturing or R&D work. The wrong frame type can lead to part inaccuracies, increased tooling wear, and production bottlenecks.

KINTEK specializes in lab equipment and consumables, providing expert guidance to help you select the perfect machinery for your specific application. Whether you need the versatility of a C-type press for varied tasks or the precision of an H-type press for demanding production, we have the solutions to enhance your operational reliability.

Contact our experts today for a personalized consultation. We'll help you analyze your needs to ensure you invest in a press that delivers superior performance and protects your tooling investment.

Reach out to our team now via our contact form to discuss your power press requirements!

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What role does a laboratory hydraulic hot press play in rice husk-based composite boards? Achieve Structural Density

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces

- Why is a heated hydraulic press used for warm pressing NASICON green tapes? Optimize Your Solid Electrolyte Density

- What is the function of a laboratory hydraulic hot press in the assembly of solid-state photoelectrochemical cells?

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating