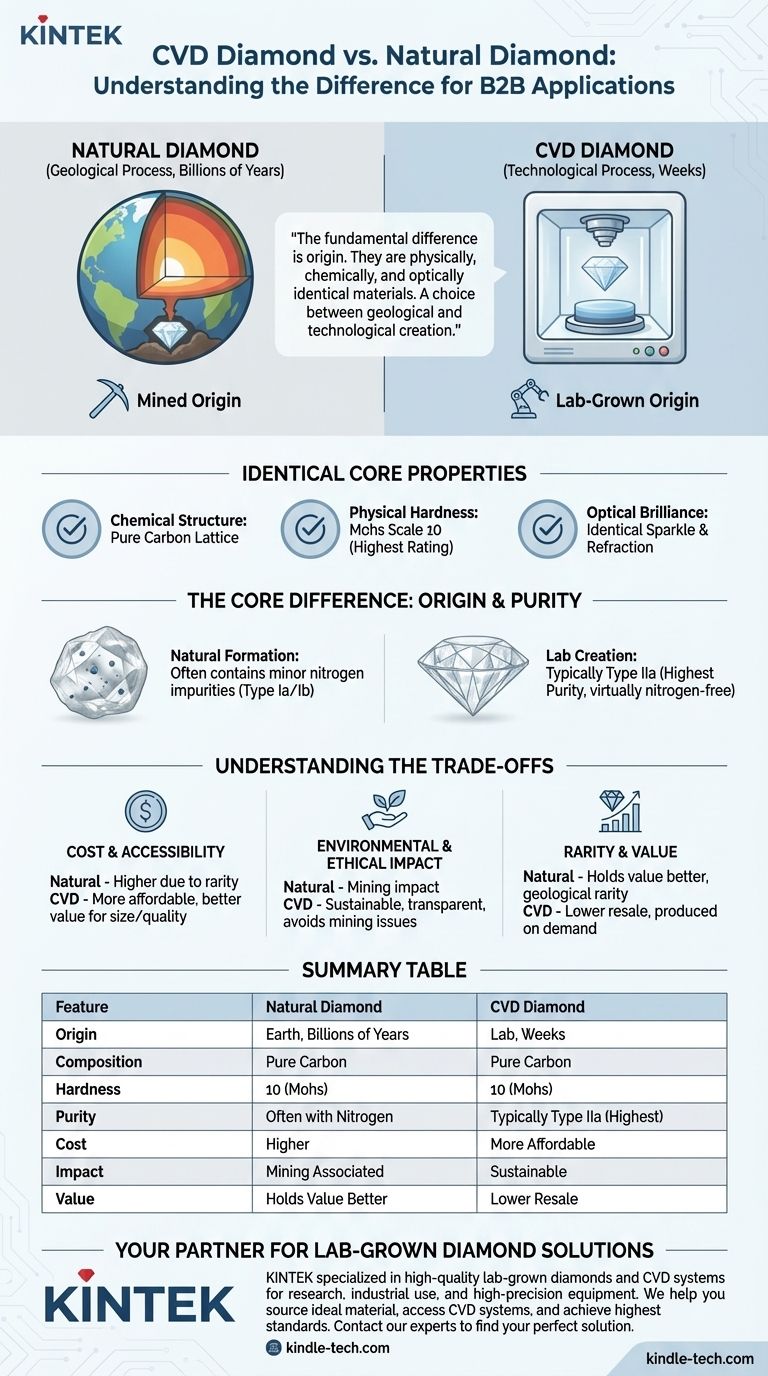

The fundamental difference between a CVD diamond and a natural diamond is its origin. A natural diamond is formed over billions of years under the Earth's crust, while a CVD (Chemical Vapor Deposition) diamond is grown in a laboratory in a matter of weeks. Despite these vastly different origins, they are physically, chemically, and optically identical materials.

Your decision is not between a "real" and a "fake" diamond. It is a choice between a diamond created by a geological process and one created by a technological process. Both are real diamonds, but the lab-grown method often produces a stone with higher purity at a more accessible price point.

What "Chemically Identical" Really Means

When experts say these two types of diamonds are the same, it refers to their core properties. Without specialized gemological equipment, even a trained jeweler cannot tell them apart.

Identical Chemical Structure

Both natural and CVD diamonds are made of pure carbon atoms arranged in the same rigid crystal lattice structure. This shared atomic makeup is the foundation for all their other identical properties.

Identical Physical Hardness

Both types of diamonds score a perfect 10 on the Mohs scale of hardness, the highest possible rating. This means a CVD diamond is just as durable and resistant to scratching as a mined diamond, making it equally suitable for everyday wear.

Identical Optical Brilliance

The way a diamond reflects and refracts light—its fire, brilliance, and sparkle—is a product of its crystal structure and cut. Because the structure is the same, a well-cut CVD diamond will exhibit the same intense sparkle as a well-cut natural diamond.

The Core Difference: Origin and Purity

While they are the same material, the journey each diamond takes to its final form is profoundly different. This journey is what creates the most significant distinctions in purity and cost.

Formation by Nature

Natural diamonds form under conditions of extreme heat and pressure deep within the Earth's mantle over a period of 1 to 3 billion years. During this chaotic and lengthy process, other elements, most commonly nitrogen, often become trapped within the crystal, creating minor impurities.

Creation by Technology

CVD diamonds are grown in a highly controlled laboratory environment. The process starts with a thin "seed" of a diamond slice, which is placed in a sealed chamber. This chamber is heated and filled with carbon-rich gases, which break down and deposit onto the seed, growing a pure diamond crystal, layer by layer.

The Purity Advantage

The controlled environment of a lab gives CVD diamonds a distinct advantage in purity. Most CVD diamonds are classified as Type IIa, the purest form of diamond, which is virtually free of nitrogen impurities.

In contrast, only about 5% of all natural diamonds are Type IIa. This higher purity can make CVD diamonds appear exceptionally white, bright, and flawless.

Understanding the Trade-offs

Choosing between a natural and a CVD diamond involves weighing a few key practical considerations. There is no single "better" option; the right choice depends entirely on your priorities.

Cost and Accessibility

This is the most significant practical difference. The ability to produce diamonds in a lab in weeks, rather than relying on intensive mining operations, makes CVD diamonds significantly more affordable. You can often acquire a larger, higher-quality lab-grown diamond for the same budget as a smaller natural one.

Environmental and Ethical Impact

Lab-grown diamonds bypass the traditional mining process entirely. This means they do not contribute to the environmental disruption or potential ethical conflicts sometimes associated with diamond mining, offering a more transparent and sustainable choice.

Rarity and Perceived Value

The value of a natural diamond is intrinsically tied to its finite supply and geological rarity. A lab-grown diamond, while physically identical, can be produced on demand. This distinction means that natural diamonds have historically held their value better over the long term, while the resale value of lab-grown diamonds is generally lower.

Making the Right Choice for Your Goal

Your decision should be guided by what you value most in a diamond.

- If your primary focus is maximizing size and quality for your budget: A CVD diamond is the clear choice, offering superior purity and a larger stone for the price.

- If your primary focus is tradition and long-term value retention: A natural diamond's rarity and billion-year-old origin story carry a unique legacy and historical value.

- If your primary focus is ethical sourcing and environmental impact: A lab-grown diamond provides a definitive and verifiable solution that avoids the concerns of mining.

Ultimately, the choice is between the unique story of geological rarity and the impressive achievements of modern technology.

Summary Table:

| Feature | Natural Diamond | CVD Diamond |

|---|---|---|

| Origin | Formed over billions of years in the Earth | Grown in a lab in weeks |

| Chemical Composition | Pure Carbon | Pure Carbon |

| Hardness (Mohs Scale) | 10 | 10 |

| Typical Purity | Often contains nitrogen impurities | Typically Type IIa (highest purity) |

| Cost | Higher due to rarity and mining | More affordable, better value for size/quality |

| Ethical & Environmental Impact | Associated with mining | More sustainable and transparent choice |

| Long-Term Value | Historically holds value better | Lower resale value |

Still Unsure Which Diamond is Right for Your Application?

Whether you require diamonds for research, industrial use, or high-precision laboratory equipment, the choice of material is critical. KINTEK specializes in providing high-quality lab-grown diamonds and the equipment needed for advanced material science.

We can help you:

- Source the ideal diamond material for your specific thermal, optical, or mechanical requirements.

- Access CVD systems for your own in-house diamond growth and research.

- Benefit from our expertise to ensure your project achieves the highest standards of performance and purity.

Let's discuss your needs. Contact our experts today to find the perfect diamond solution for your laboratory.

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Dressing Tools for Precision Applications

- CVD Diamond Optical Windows for Lab Applications

People Also Ask

- What are 5 negative impacts of diamond mines on the environment? The Hidden Environmental Cost of Diamond Mining

- Can you chemically make diamonds? Yes, CVD & HPHT Create Real Diamonds

- How does microwave plasma work? Unlock Precision Material Synthesis for Advanced Manufacturing

- What are the technical advantages of using a low-pressure microwave plasma reactor? Room Temperature Polymer Synthesis

- What is the process of MPCVD? Grow High-Purity Diamond & Advanced Films

- Can a jeweler distinguish a lab grown diamond? The Truth About Identifying Diamond Origin

- What is the fluorescence of a CVD diamond? A Guide to Its Unique Glow and Purpose

- What is the difference between MPCVD and HFCVD? Choose the Right CVD Method for Your Application