In short, a CVD diamond can exhibit fluorescence, but it is typically less common and often displays different characteristics compared to many natural or other lab-grown diamonds. The presence, color, and intensity of this glow under ultraviolet (UV) light are directly linked to the specific conditions of its creation and are not a universal trait of all CVD stones.

The fluorescence in a CVD diamond is not an inherent property but a byproduct of its specific growth process and any subsequent treatments. Understanding this allows you to interpret fluorescence not as a simple flaw, but as a fingerprint of its creation, with implications for both its aesthetic appeal and technical function.

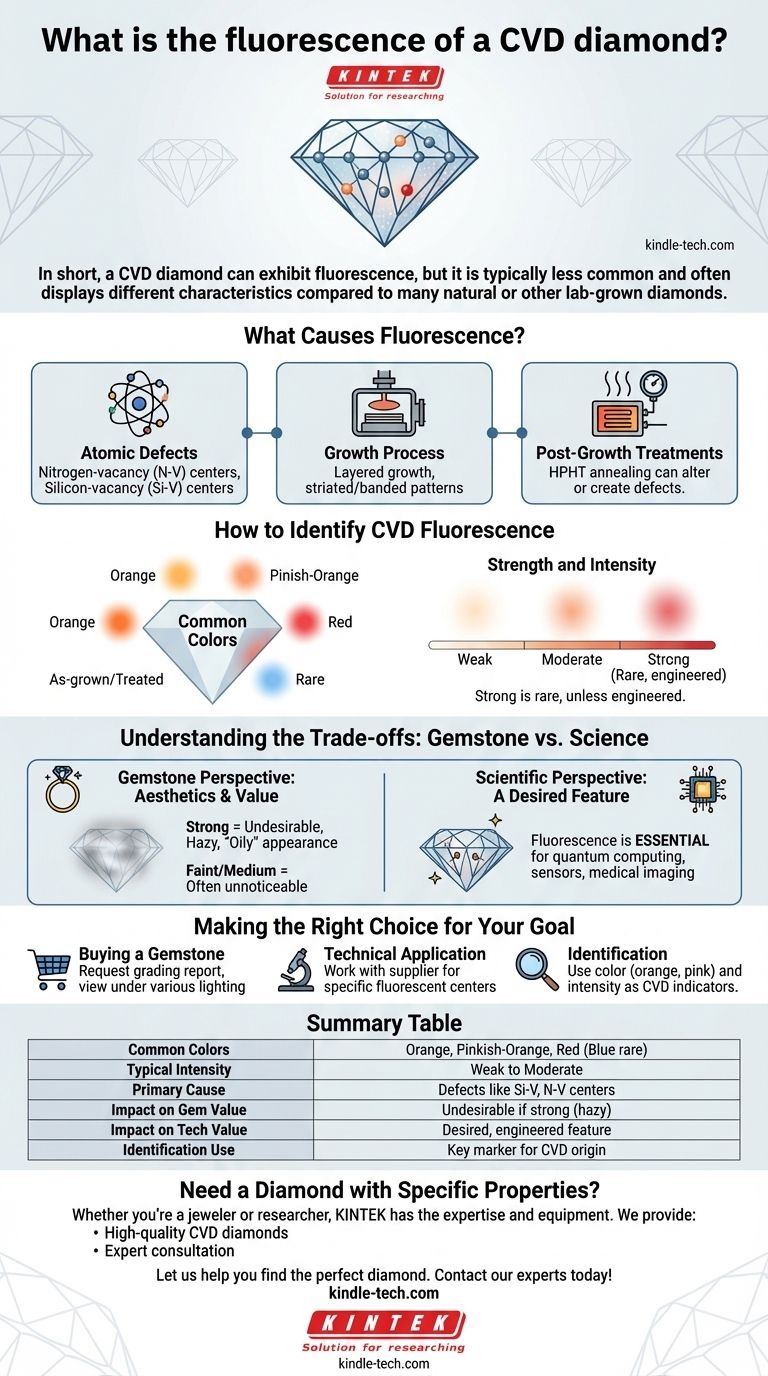

What Causes Fluorescence in CVD Diamonds?

The glow you see in a fluorescent diamond is caused by trace elements and structural irregularities within its crystal lattice that absorb UV light and re-emit it as visible color. In CVD diamonds, these are introduced in a unique way.

The Role of Atomic-Level Defects

A diamond is ideally a pure lattice of carbon atoms. However, during the chaotic, high-energy CVD growth process, other atoms can be incorporated into the structure, creating what are known as "color centers" or defects.

Nitrogen is a common impurity in natural diamonds, but in CVD diamonds, nitrogen-vacancy (N-V) centers and silicon-vacancy (Si-V) centers are frequent sources of fluorescence.

The Influence of the Growth Process

The CVD method involves growing the diamond layer by layer in a chamber filled with carbon-rich gases. The precise mixture of these gases and the conditions inside the chamber determine which trace elements or structural defects are incorporated.

Because of this layered growth, CVD diamonds can sometimes show striated or banded fluorescence patterns that follow the direction of their growth, a feature gemologists look for.

The Impact of Post-Growth Treatments

Many CVD diamonds undergo a post-growth treatment like High-Pressure/High-Temperature (HPHT) annealing to improve their color. This process can alter or even create the structural defects responsible for fluorescence, changing its intensity or color.

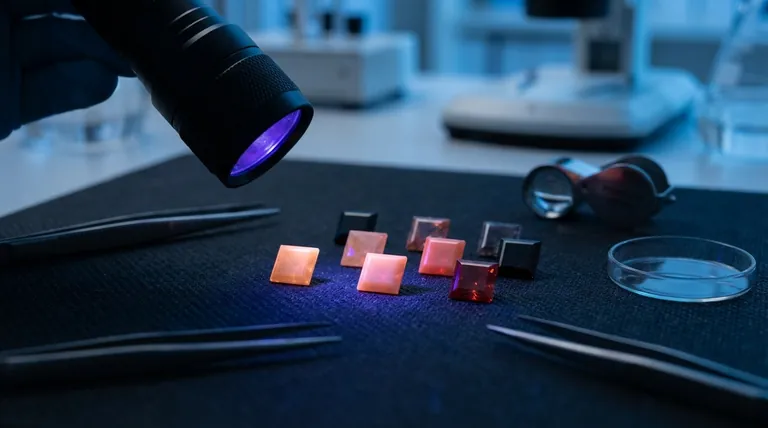

How to Identify CVD Fluorescence

While natural diamonds most commonly fluoresce blue, CVD diamonds have a different and more varied palette. This difference is a critical tool for identification.

Common Colors: Orange, Pink, and Red

The most characteristic fluorescence colors for as-grown or treated CVD diamonds are orange, pinkish-orange, or red. While blue is possible, it is far less common than in the natural diamond population.

This distinct color profile is one of the first indicators a gemologist uses to suspect a diamond may be a CVD lab-grown stone.

Strength and Intensity

Fluorescence in CVD diamonds is typically weak to moderate. It is rare to find a CVD diamond with the very strong fluorescence that can sometimes be seen in natural diamonds.

Strong fluorescence is generally only present when it has been intentionally engineered for a specific scientific purpose.

Understanding the Trade-offs: Is Fluorescence Good or Bad?

The desirability of fluorescence depends entirely on the diamond's intended use. What is considered a flaw in a gemstone can be the most critical feature in a technical component.

The Gemstone Perspective: Aesthetics and Value

In jewelry, strong fluorescence of any color is often considered undesirable because it can give the diamond a hazy or "oily" appearance in sunlight. This can negatively impact the stone's beauty and market value.

However, faint to medium fluorescence is usually unnoticeable to the naked eye and has little to no impact on appearance.

The Scientific Perspective: A Desired Feature

For many advanced technology applications, fluorescence is not a bug—it's the feature. Scientists and engineers intentionally create CVD diamonds with specific defects, like N-V centers, because their predictable fluorescence is essential for applications in quantum computing, high-sensitivity sensors, and advanced medical imaging.

Fluorescence as an Identification Marker

For gemologists, fluorescence is a vital, non-destructive clue to a diamond's origin. The combination of color, intensity, and potential growth patterns helps them differentiate CVD diamonds from natural diamonds and other lab-grown types like HPHT.

Making the Right Choice for Your Goal

Evaluating a CVD diamond's fluorescence requires you to consider your objective.

- If your primary focus is buying a gemstone: Request a grading report that specifies the fluorescence color and intensity, and always view the diamond under various lighting conditions, including direct sunlight.

- If your primary focus is technical or scientific application: Work directly with a materials supplier to specify the exact type and density of fluorescent color centers required for your purpose.

- If your primary focus is identification: Use fluorescence color (especially orange or pink) in conjunction with other gemological observations as a strong indicator of a potential CVD origin.

Ultimately, a CVD diamond's fluorescence tells a story about its origin and engineering, empowering you to evaluate its fitness for your specific purpose.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Common Colors | Orange, Pinkish-Orange, Red (Blue is rare) |

| Typical Intensity | Weak to Moderate |

| Primary Cause | Defects like Silicon-Vacancy (Si-V) centers from the growth process |

| Impact on Gem Value | Often considered undesirable if strong, can cause a hazy appearance |

| Impact on Tech Value | A desired, engineered feature for quantum computing and sensors |

| Identification Use | A key marker for gemologists to identify CVD origin |

Need a Diamond with Specific Properties?

Whether you're a jeweler seeking a flawless stone or a researcher requiring a diamond with precisely engineered fluorescence for a quantum application, KINTEK has the expertise and equipment to meet your needs.

As a specialist in advanced lab equipment and materials, we provide:

- High-quality CVD diamonds tailored for both gemological and technological uses.

- Expert consultation to help you select the right material based on fluorescence and other critical properties.

Let us help you find the perfect diamond for your project. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Dressing Tools for Precision Applications

- CVD Diamond Optical Windows for Lab Applications

People Also Ask

- Are CVD diamonds better than HPHT? The Real Truth About Lab-Grown Diamond Quality

- What is CVD diamond? The Ultimate Guide to Lab-Grown Diamonds and Their Uses

- What is the process of lab created diamonds? A Clear Guide to HPHT & CVD Methods

- What is the future of CVD diamond? Unlocking Next-Gen Electronics & Thermal Management

- What is the future value of lab grown diamond? Understanding Its Depreciating Financial Worth