At their core, an electric oven and a muffle furnace are distinguished by their maximum temperature and fundamental design purpose. While both use electricity to generate heat, an electric oven is designed for low-temperature applications like drying and warming, whereas a muffle furnace is a specialized instrument built for high-temperature material processing and transformation.

The critical difference lies not in the power source, but in the purpose. An electric oven is a general-purpose heater, while a muffle furnace is a high-temperature, contamination-free chamber designed to fundamentally change the properties of the materials placed inside it.

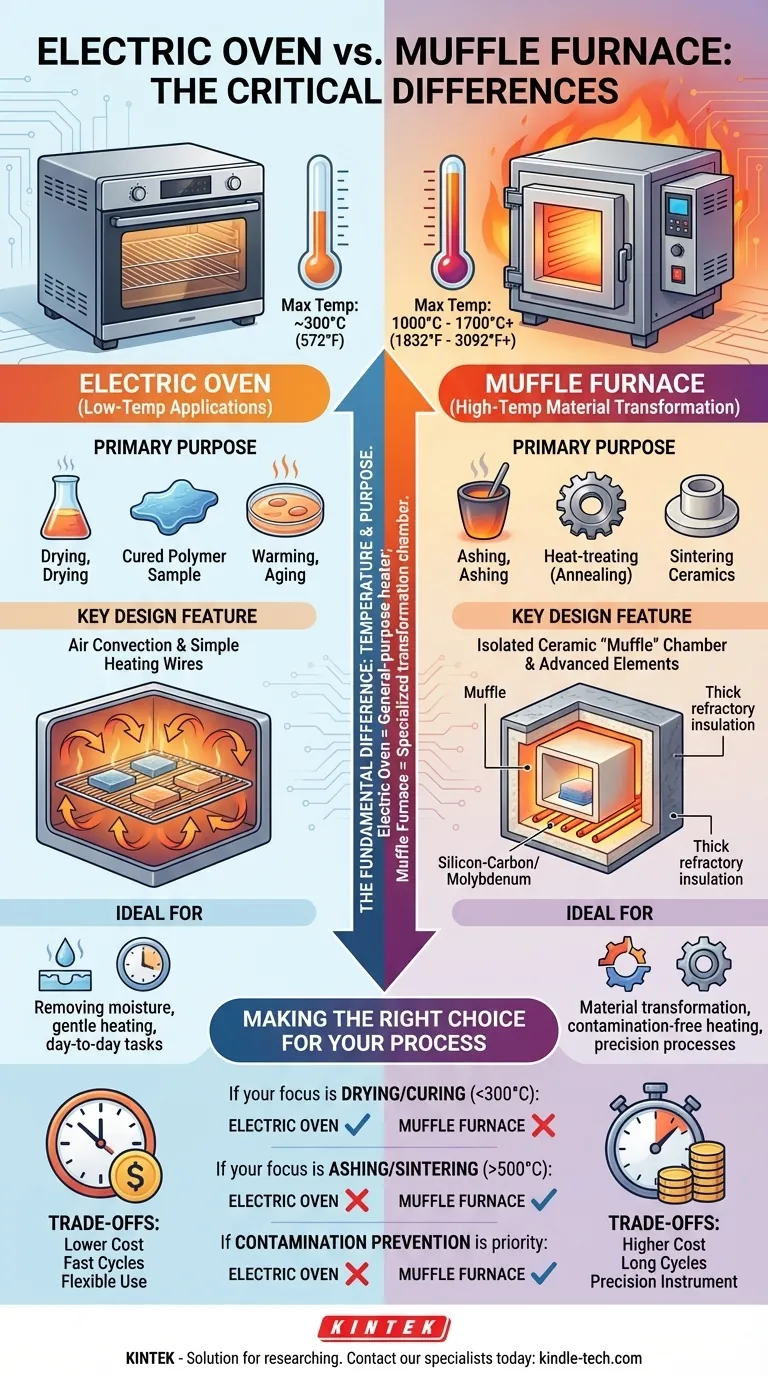

The Fundamental Difference: Temperature and Purpose

The most significant distinction between these two devices is the temperature range they operate in and the tasks they are designed to perform.

Electric Ovens: Low-Temperature Applications

An electric laboratory oven, often called a drying or convection oven, typically operates in a range from slightly above ambient temperature up to around 300°C (572°F).

Their primary function is not to alter the chemical nature of a substance but to perform tasks like drying glassware, removing moisture from samples, curing polymers, or conducting gentle aging tests.

Muffle Furnaces: High-Temperature Material Transformation

A muffle furnace is engineered for extremely high temperatures, commonly starting around 1000°C and capable of reaching 1700°C (3092°F) or higher.

Their purpose is to induce significant chemical or physical changes in a material. Common applications include ashing samples to determine inorganic content, heat-treating metals (annealing), and sintering ceramics.

A Closer Look at Design and Construction

The dramatic difference in temperature capability is a direct result of fundamental differences in how each device is built.

The "Muffle": Isolating the Sample

The defining feature of a muffle furnace is the "muffle" itself—an inner chamber, typically made of high-temperature ceramic.

This chamber isolates the sample from the raw heating elements. This design serves two critical functions: it prevents any contamination of the sample from the elements and ensures incredibly uniform heating through radiation within the chamber.

Heating Elements and Insulation

Electric ovens use simple heating wires, but muffle furnaces require more advanced components to reach and sustain extreme temperatures.

According to temperature requirements, these can be electric heating wires (up to 1200°C), silicon-carbon rods (up to 1400°C), or silicon molybdenum rods (up to 1700°C). This is paired with thick, multi-layered refractory insulation to contain the intense heat safely and efficiently.

Atmosphere Control

In a standard oven, air is simply circulated, meaning any fumes or outgassing from samples is spread throughout the chamber.

In a muffle furnace, the isolated muffle provides a more controlled environment. This is essential for processes where reacting with atmospheric gases or contaminants from heating elements would ruin the result.

Understanding the Trade-offs

Choosing the wrong instrument is not just inefficient; it can compromise your results.

Cost and Energy Consumption

Muffle furnaces are significantly more expensive to purchase and operate. Reaching and maintaining temperatures over 1000°C requires a tremendous amount of electrical energy compared to the modest needs of a 200°C oven.

Process Time and Flexibility

Due to their massive thermal insulation, muffle furnaces have very long heat-up and cool-down cycles. They are typically used for long, pre-programmed batch processes.

An electric oven, by contrast, heats and cools relatively quickly, making it more flexible for varied, day-to-day laboratory tasks.

Precision vs. General Use

Using a muffle furnace for a simple drying task is extreme overkill. It is an inefficient use of a precision instrument. Likewise, attempting to ash a sample in a standard lab oven is impossible, as it simply cannot generate the required heat.

Making the Right Choice for Your Process

Your choice should be dictated entirely by the temperature and environmental control your specific process requires.

- If your primary focus is drying, curing, or sterilizing below 300°C: An electric laboratory oven is the correct and most efficient choice.

- If your primary focus is determining ash content, heat-treating metals, or sintering ceramics (above 500°C): You require a muffle furnace for its high-temperature capability.

- If preventing sample contamination from heating elements is your top priority: The isolated chamber of a muffle furnace is non-negotiable, even for lower-temperature applications.

Understanding this distinction ensures you select not just a heating device, but the precise instrument your scientific process demands.

Summary Table:

| Feature | Electric Laboratory Oven | Muffle Furnace |

|---|---|---|

| Primary Purpose | Drying, curing, warming | Ashing, heat-treating, sintering |

| Max Temperature | ~300°C (572°F) | 1000°C - 1700°C+ (1832°F - 3092°F+) |

| Key Design Feature | Air convection | Isolated ceramic muffle chamber |

| Ideal For | Removing moisture, gentle heating | Material transformation, contamination-free heating |

Still unsure which heating equipment is right for your lab's specific processes?

KINTEK specializes in precision lab equipment and consumables, serving diverse laboratory needs. Our experts can help you select the perfect instrument—whether a standard electric oven for drying or a high-temperature muffle furnace for advanced material testing—ensuring efficiency, accuracy, and safety for your applications.

Contact our specialists today for a personalized consultation and discover the right solution for your laboratory!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do you run a muffle furnace? Master the Step-by-Step Process for Safe, Precise Results

- What is the meaning of muffle furnace? The Key to Pure, High-Temperature Processing

- How do you keep a sample in a muffle furnace? A Guide to Safe and Accurate Placement

- What is the significance of a muffle furnace? Achieve Uncontaminated, High-Purity Heating

- What type of furnace is a muffle furnace? A Guide to High-Purity, Contamination-Free Heating