In essence, the primary difference is their operating temperature and intended purpose. An air oven is designed for lower-temperature applications like drying, curing, and general heating, typically operating well below 500°C. A muffle furnace is a specialized piece of equipment built to reach much higher temperatures, often exceeding 1000°C, for processes that transform materials, such as ashing, sintering, or heat-treating metals.

The choice between an oven and a muffle furnace is not about which is superior, but which tool is engineered for your specific thermal process. Ovens are for heating and drying; furnaces are for fundamentally changing or analyzing a material at extreme temperatures.

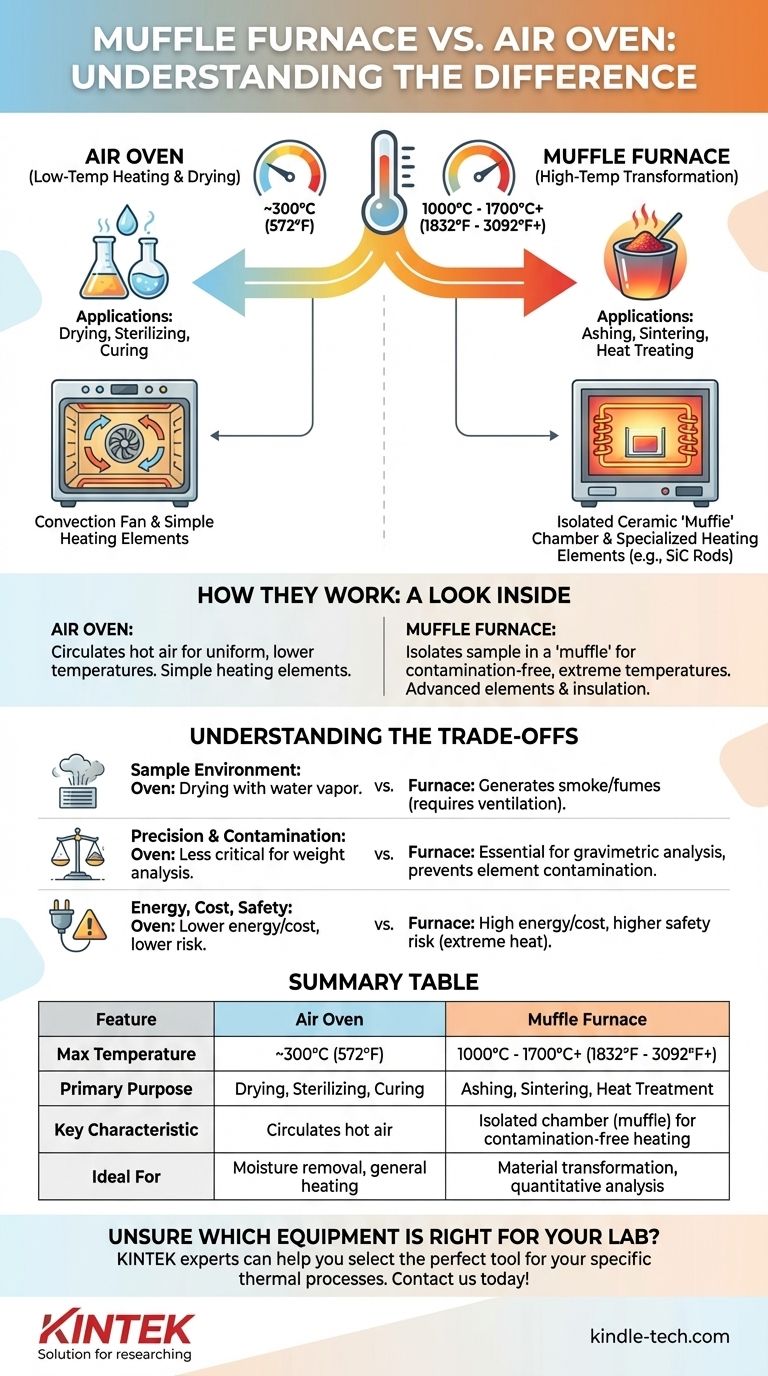

The Fundamental Difference: Temperature and Purpose

The most significant distinction lies in the thermal range each device is designed to handle and the scientific or industrial processes this enables.

Air Ovens: Low-Temperature Heating and Drying

An air oven, sometimes called a convection or laboratory oven, is designed for uniform heating at relatively low temperatures. They typically operate from just above ambient to around 300°C (572°F).

Their primary function is to remove moisture or perform simple thermal tests. Common applications include drying laboratory glassware, sterilizing equipment, curing polymers, and conducting stability testing on electronic components.

Muffle Furnaces: High-Temperature Transformation

A muffle furnace is engineered for processes that require extreme heat, generally starting around 500°C (932°F) and capable of reaching 1700°C (3092°F) or more.

These high temperatures are not for simple drying but for inducing chemical or physical changes in a material. This includes applications like ashing (burning off organic material to determine inorganic content), sintering (fusing powdered material together), loss-on-ignition analysis, and metallurgical heat treatments.

How They Work: A Look at Construction

The difference in purpose dictates a significant difference in their internal construction, especially concerning insulation and heating elements.

The "Muffle": Protecting the Sample

The key feature of a muffle furnace is the "muffle" itself—a chamber that isolates the sample from the heating elements. This chamber is typically made from high-temperature ceramic fiber insulation.

This design serves two critical functions:

- It enables rapid heating and excellent temperature stability.

- It prevents contamination, as the sample is not exposed to the electric heating elements, which is vital for precise quantitative analysis.

High-Temperature Heating Elements

To achieve such extreme temperatures, muffle furnaces use specialized heating components that are chosen based on the required temperature range.

- Up to 1200°C: Standard electric heating wires are used.

- 1300°C to 1400°C: More robust silicon-carbon rods are required.

- 1400°C to 1700°C: High-performance silicon molybdenum rods are necessary.

In contrast, a standard air oven uses simpler heating elements and a fan to circulate hot air, which is sufficient for its lower temperature range but inadequate for high-heat applications.

Understanding the Trade-offs

Choosing the wrong instrument can lead to failed experiments, damaged equipment, or inaccurate results. Understanding their limitations is crucial.

Sample Environment and Fumes

An air oven simply circulates air, making it suitable for drying with water vapor. A muffle furnace, when used for processes like ashing, generates smoke and corrosive fumes as the sample combusts. This requires proper ventilation and careful material selection for the furnace chamber.

Precision and Contamination

For analytical work like gravimetric analysis, where the final weight of the sample is critical, a muffle furnace is essential. Its design prevents flakes from the heating elements from falling into and contaminating the sample, ensuring analytical accuracy.

Energy, Cost, and Safety

A muffle furnace consumes significantly more energy than an oven. The advanced insulation and specialized heating elements also make it a more expensive piece of equipment. The extreme temperatures present a higher safety risk, requiring more stringent operating procedures.

Making the Right Choice for Your Application

Your final decision must be driven by the specific thermal process you need to perform.

- If your primary focus is drying, sterilizing, or general heating below 300°C: An air oven is the correct, cost-effective tool for the job.

- If your primary focus is ashing, loss-on-ignition, or quantitative analysis: You require a muffle furnace for its high temperatures and clean, non-contaminating heating chamber.

- If your primary focus is sintering ceramics or performing metallurgical heat treatments: A muffle furnace is the only option capable of reaching the necessary extreme temperatures.

By aligning the equipment's capability with your specific application, you ensure you are investing in the right tool to achieve precise and repeatable results.

Summary Table:

| Feature | Air Oven | Muffle Furnace |

|---|---|---|

| Max Temperature | ~300°C (572°F) | 1000°C - 1700°C+ (1832°F - 3092°F+) |

| Primary Purpose | Drying, Sterilizing, Curing | Ashing, Sintering, Heat Treatment |

| Key Characteristic | Circulates hot air | Isolated chamber (muffle) for contamination-free heating |

| Ideal For | Moisture removal, general heating | Material transformation, quantitative analysis |

Unsure which equipment is right for your lab's specific thermal processes?

KINTEK specializes in providing the precise lab equipment you need. Whether your application requires the high-temperature capabilities of a muffle furnace for ashing and sintering or the controlled, lower-temperature environment of an air oven for drying and curing, our experts can help you select the perfect tool.

Contact us today via our contact form to discuss your requirements and ensure you invest in the right solution for accurate, repeatable results.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the capacity of a muffle furnace? Find the Right Size for Your Lab Needs

- What is the cooling rate for a muffle furnace? Achieve Optimal Cooling for Your Lab Processes

- What is the use of muffle furnace in pharmaceuticals? Essential for Purity & Quality Control

- What is the tolerance of a muffle furnace? A Guide to Temperature Accuracy & Uniformity

- What is the use of muffle furnace in chemistry? Achieve Contaminant-Free Heating for Accurate Analysis