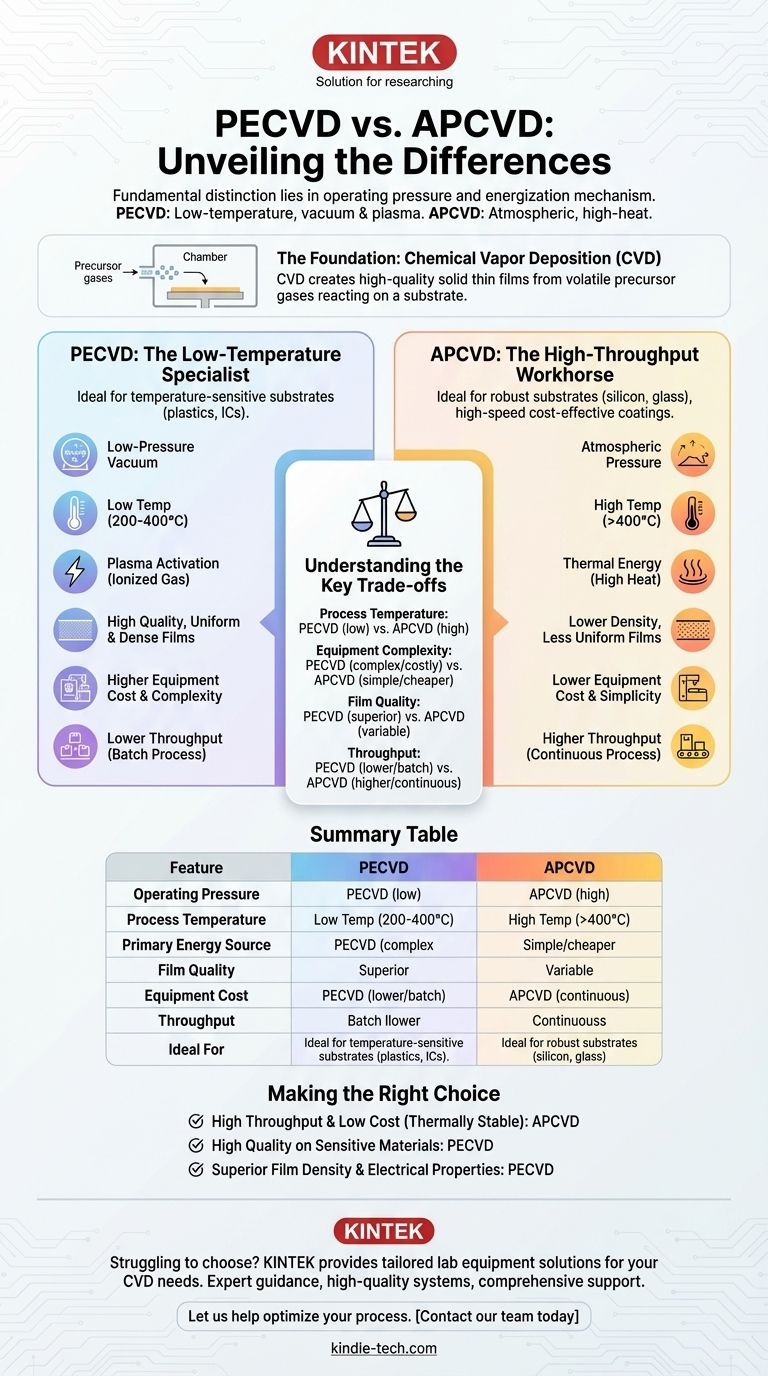

The fundamental difference between PECVD and APCVD lies in their operating pressure and the mechanism used to energize the chemical reaction. PECVD (Plasma-Enhanced Chemical Vapor Deposition) uses a low-pressure vacuum and plasma to deposit films at low temperatures. In contrast, APCVD (Atmospheric Pressure Chemical Vapor Deposition) operates at normal atmospheric pressure and typically relies on high heat to drive the reaction.

While both are methods for creating thin films, PECVD is a low-temperature, vacuum-based process prized for quality on sensitive substrates, whereas APCVD is a high-speed, atmospheric process optimized for throughput and cost-effectiveness.

The Foundation: What is Chemical Vapor Deposition (CVD)?

The Core Principle

Chemical Vapor Deposition (CVD) is a family of processes used to create high-quality, solid thin films on a substrate.

The basic mechanism involves introducing volatile precursor gases into a reaction chamber. These gases then react or decompose on the substrate's surface to form the desired solid material.

A Closer Look at the Two Methods

While both PECVD and APCVD fall under the CVD umbrella, their distinct operating conditions lead to vastly different capabilities and applications.

APCVD: The High-Throughput Workhorse

APCVD operates at standard atmospheric pressure, meaning it does not require an expensive and complex vacuum system.

Because it lacks a vacuum, the process typically relies on very high temperatures (often >400°C) to provide the thermal energy needed to break down the precursor gases and initiate the film-forming reaction.

This simplicity and high deposition rate make it ideal for applications where speed and cost are more critical than perfect film quality, such as creating thick layers of silicon dioxide for solar cells or protective coatings.

PECVD: The Low-Temperature Specialist

PECVD operates under a low-pressure vacuum. This controlled environment is crucial for its primary advantage.

Instead of relying solely on heat, PECVD introduces energy into the system by creating plasma—an ionized gas. This plasma bombards the precursor gases, breaking them down into reactive species at much lower temperatures (often 200-400°C).

This low-temperature capability is essential for depositing films onto substrates that cannot withstand high heat, such as plastics, integrated circuits with existing metal layers, or other sensitive electronic components.

Understanding the Key Trade-offs

Choosing between these methods involves a clear set of engineering trade-offs. The decision is almost never about which is "better" overall, but which is correct for a specific goal.

Process Temperature

PECVD has a major advantage in its low deposition temperature, enabling its use on a wide variety of temperature-sensitive materials.

APCVD requires high temperatures, which limits its use to robust substrates like silicon wafers or certain types of glass that can tolerate the thermal stress.

Equipment Complexity and Cost

APCVD systems are relatively simple and less expensive. They do not require vacuum pumps or the sophisticated radio-frequency (RF) power systems needed to generate plasma.

PECVD systems are significantly more complex and costly due to the required vacuum chamber, pumps, and plasma generation hardware.

Film Quality and Uniformity

PECVD generally produces films with higher density, better uniformity, and superior electrical properties. The plasma process and vacuum environment provide greater control over the film's chemical composition and structure.

APCVD films often have lower density and can be less uniform. The atmospheric process is harder to control precisely, which can impact the final material characteristics.

Throughput and Speed

APCVD is typically a much faster process, capable of high deposition rates. It can also be implemented in a continuous, conveyor-style system, making it excellent for high-volume manufacturing.

PECVD is usually a slower, batch-based process. Loading and unloading substrates into the vacuum chamber limits its overall throughput compared to continuous APCVD.

Making the Right Choice for Your Goal

Your application's specific requirements for temperature, quality, and speed will dictate the correct choice.

- If your primary focus is high throughput and low cost for thermally stable substrates: APCVD is the clear choice for its speed and simpler equipment.

- If your primary focus is depositing high-quality films on temperature-sensitive materials: PECVD is necessary because its plasma process allows for significantly lower processing temperatures.

- If your primary focus is achieving superior film density, uniformity, and electrical properties: PECVD offers greater control over the deposition process, resulting in higher-performance films.

Ultimately, the choice between PECVD and APCVD is a strategic decision balancing the need for processing speed and cost against the required film quality and substrate limitations.

Summary Table:

| Feature | PECVD (Plasma-Enhanced CVD) | APCVD (Atmospheric Pressure CVD) |

|---|---|---|

| Operating Pressure | Low-pressure vacuum | Atmospheric pressure |

| Process Temperature | Low (200-400°C) | High (>400°C) |

| Primary Energy Source | Plasma activation | Thermal energy (heat) |

| Film Quality | High density, excellent uniformity | Lower density, less uniform |

| Equipment Cost | Higher (vacuum & plasma systems) | Lower (simpler setup) |

| Throughput | Lower (batch process) | Higher (continuous process) |

| Ideal For | Temperature-sensitive substrates, high-quality films | High-throughput, cost-effective coatings |

Struggling to choose between PECVD and APCVD for your thin-film deposition needs?

At KINTEK, we specialize in providing tailored lab equipment solutions for all your chemical vapor deposition requirements. Whether you need the low-temperature precision of PECVD for sensitive electronics or the high-throughput efficiency of APCVD for industrial coatings, our experts can help you select the perfect system.

We offer:

- Expert guidance on CVD technology selection

- High-quality PECVD and APCVD systems

- Comprehensive support for laboratory equipment and consumables

Let us help you optimize your deposition process. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is CVD technique? A Guide to High-Performance Thin Film Manufacturing

- What is the advantage of chemical Vapour deposition over oxidation? Unmatched Versatility in Thin Film Deposition

- What is the difference between chemical vapour deposition and physical Vapour deposition? A Guide to Choosing the Right Thin-Film Coating Process

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What is the purpose of a DC bias power supply in growing vertical graphene nanowalls? Control Ion Direction and Growth

- What are the characteristics of physical Vapour deposition? A Guide to Precision Thin-Film Coatings

- What is the process of vacuum deposition coating? Create High-Performance, Durable Thin Films

- What are the benefits of atomic layer deposition? Achieve Unmatched Precision in Thin-Film Creation