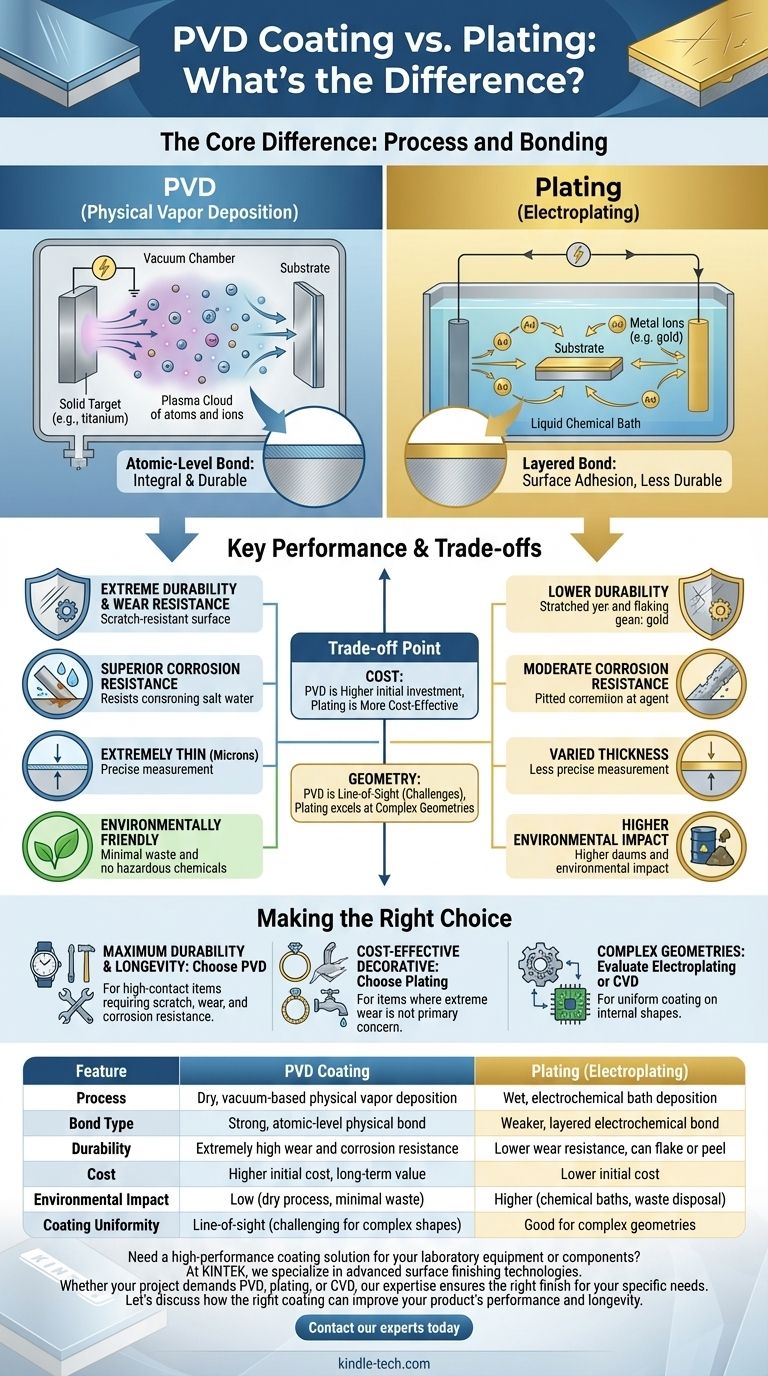

The core difference between PVD coating and plating lies in the application process and the nature of the bond created. PVD (Physical Vapor Deposition) is a vacuum deposition method that physically bonds a thin film to a surface at an atomic level, creating an extremely durable finish. In contrast, traditional plating (electroplating) uses an electrochemical process in a liquid bath to deposit a layer of metal onto a surface, which is less integrated and less durable.

Your choice between these two processes comes down to a fundamental trade-off. Plating offers a cost-effective way to achieve a desired surface finish, while PVD provides a high-performance, long-lasting solution that is far more resistant to wear and corrosion.

The Fundamental Difference: Process and Bonding

To understand the practical outcomes of each method, you must first understand how they work. The "how" dictates the durability, cost, and application suitability of the final product.

How PVD Works: A Physical Bond in a Vacuum

PVD is a dry coating process performed in a high-vacuum chamber. It is not a liquid dip or a chemical reaction in the traditional sense.

The process involves vaporizing a solid source material, such as titanium or zirconium, into a plasma of atoms or ions. A high-voltage electrical charge then guides these particles to the target object, where they condense and form a thin, tightly bonded film.

Think of it as a form of atomic-level bonding. The deposited material becomes an integral part of the surface rather than just a superficial layer sitting on top.

How Plating Works: An Electrochemical Deposit

The most common form of plating is electroplating. This process involves submerging the object (the substrate) into a chemical bath containing dissolved ions of the metal to be plated, such as gold or nickel.

An electrical current is passed through the bath, causing the metal ions to migrate and deposit onto the substrate's surface. This creates a new metallic layer, but it is a distinct layer adhered to the top of the base material.

A Note on CVD (Chemical Vapor Deposition)

It is also useful to distinguish PVD from CVD. While both are vapor deposition methods, CVD uses chemical reactions between precursor gases to create the film on the substrate's surface. CVD excels at creating highly uniform (conformal) coatings, even on complex internal geometries.

Comparing Key Performance Metrics

The differences in the application process lead to significant variations in performance, which is often the deciding factor in choosing a finish.

Durability and Wear Resistance

PVD is significantly more durable than plating. Because the coating is bonded at an atomic level, it is incredibly hard and highly resistant to scratches and abrasion. It will not flake or peel away.

A plated surface, by contrast, is a softer, separate layer. When scratched, the coating can be compromised, exposing the base metal underneath and leading to failure.

Corrosion Resistance

The dense, non-porous nature of a PVD coating provides a superior barrier against corrosion from sweat, salt water, and other environmental factors.

While plating offers some corrosion protection, any scratch or imperfection in the coating becomes a point of failure where corrosion can begin and spread under the plated layer.

Appearance and Thickness

Both processes can achieve a wide range of colors and finishes. However, PVD films are extremely thin—often only a few microns—yet provide their immense durability without altering the part's underlying surface texture or dimensions.

Understanding the Trade-offs

Neither technology is universally superior; they are tools designed for different goals, with distinct advantages and disadvantages.

Cost and Energy Consumption

Plating is generally a less expensive process than PVD. The equipment is less complex, and the energy requirements are lower, typically involving just a low-voltage electrical current.

PVD requires a significant capital investment in vacuum chambers and supporting technology. The process is also energy-intensive, often requiring high temperatures and powerful electrical arcs to vaporize the source material.

Environmental Impact

PVD is widely considered an environmentally friendly process. It is a dry process conducted in a vacuum, producing minimal waste and avoiding the hazardous chemicals common in electroplating.

Traditional electroplating relies on chemical baths that often contain heavy metals and acids, which require careful handling and create waste products that need specialized disposal.

Geometric Limitations

PVD is a line-of-sight process. This means it is challenging to uniformly coat deep recesses, sharp internal corners, or complex three-dimensional shapes.

Plating, because it occurs in a liquid bath, can generally coat intricate shapes more easily, though achieving perfect thickness uniformity can still be a challenge.

Making the Right Choice for Your Application

Your selection should be a deliberate decision based on the specific demands of your project.

- If your primary focus is maximum durability and longevity: Choose PVD for its superior resistance to scratches, wear, and corrosion, especially for high-contact items like watches, tools, or hardware.

- If your primary focus is cost-effectiveness for decorative purposes: Plating is a viable and traditional choice for items where extreme wear is not the primary concern.

- If your primary focus is coating complex internal geometries: Evaluate electroplating for its good coverage, or consider a process like CVD for the highest-precision, most uniform coating needs.

Understanding the fundamental process behind each finish empowers you to select a solution that aligns perfectly with your product's lifecycle and performance goals.

Summary Table:

| Feature | PVD Coating | Plating (Electroplating) |

|---|---|---|

| Process | Dry, vacuum-based physical vapor deposition | Wet, electrochemical bath deposition |

| Bond Type | Strong, atomic-level physical bond | Weaker, layered electrochemical bond |

| Durability | Extremely high wear and corrosion resistance | Lower wear resistance, can flake or peel |

| Cost | Higher initial cost, long-term value | Lower initial cost |

| Environmental Impact | Low (dry process, minimal waste) | Higher (chemical baths, waste disposal) |

| Coating Uniformity | Line-of-sight (challenging for complex shapes) | Good for complex geometries |

Need a high-performance coating solution for your laboratory equipment or components?

At KINTEK, we specialize in advanced surface finishing technologies. Whether your project demands the extreme durability of PVD coating for critical lab tools or a cost-effective plating solution for decorative parts, our expertise ensures the right finish for your specific needs.

We provide:

- Superior Durability: Protect your equipment with PVD coatings that resist wear, corrosion, and chemicals.

- Technical Expertise: Get guidance on the best process (PVD, plating, or CVD) for your application's geometry and performance requirements.

- Quality and Precision: Achieve consistent, high-quality finishes that enhance product lifespan and performance.

Let's discuss how the right coating can improve your product's performance and longevity. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance