The fundamental difference between sputtering and Physical Vapor Deposition (PVD) is not one of opposition, but of classification. Sputtering is a specific technique that falls under the broad category of PVD. Therefore, all sputtering is a form of PVD, but not all PVD is sputtering.

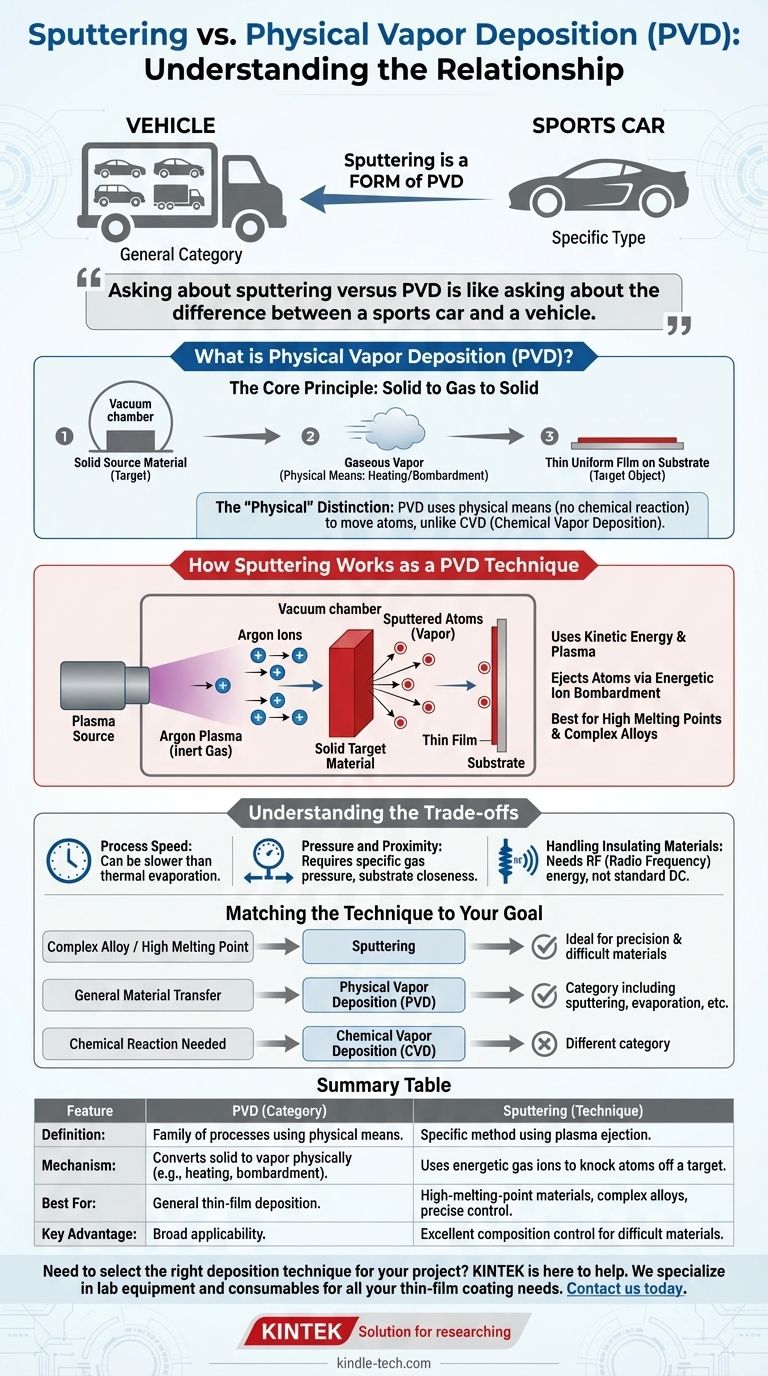

Asking about sputtering versus PVD is like asking about the difference between a sports car and a vehicle. One is a specific type (the sports car) within a general category (the vehicle). Sputtering is a specific method used to achieve the general goal of Physical Vapor Deposition.

What is Physical Vapor Deposition (PVD)?

Physical Vapor Deposition is a family of processes used to create thin films and coatings. The name itself describes the core principle.

The Core Principle: Solid to Gas to Solid

All PVD processes follow a simple, three-step sequence within a vacuum chamber.

First, a solid source material (known as the "target") is converted into a gaseous vapor. Second, this vapor is transported across the chamber. Third, it condenses back into a solid form, creating a thin, uniform film on a target object (the "substrate").

The "Physical" Distinction

The key to PVD is that this transformation from solid to gas is achieved through physical means, such as heating or energetic bombardment.

This is distinct from Chemical Vapor Deposition (CVD), where gaseous molecules undergo a chemical reaction on the substrate's surface to form the film. PVD simply moves atoms from one place to another.

How Sputtering Works as a PVD Technique

Sputtering is one of the most common and versatile PVD methods. Instead of melting the material to create a vapor, it uses kinetic energy.

The Mechanism of Ejection

The process begins by creating a plasma, typically from an inert gas like argon.

An electric field accelerates the positive argon ions from this plasma, causing them to collide with the solid target material with tremendous force.

Creating the Atomic Vapor

If the incoming ion has enough energy (typically four times the bond energy of the target's atoms), it will physically knock atoms loose from the target's surface.

These dislodged, or "sputtered," atoms are ejected into the vacuum chamber, effectively creating a vapor of the target material. They then travel and deposit onto the nearby substrate, building the thin film atom by atom.

Why Choose Sputtering?

Sputtering is highly valued for its control and versatility. It is particularly effective for depositing materials that are difficult to handle with other PVD methods.

This includes materials with extremely high melting points, like carbon or silicon, and complex alloys, as the sputtering process generally preserves the original composition of the target material in the final film.

Understanding the Trade-offs

While powerful, sputtering is not the universal solution for all PVD applications. It has specific requirements and limitations.

Process Speed

Sputtering can be a slower deposition method compared to other PVD techniques like thermal evaporation, where material is simply boiled off.

Pressure and Proximity

The process requires a specific range of gas pressure to sustain the plasma. This means it cannot operate at the extremely low pressures used by some other techniques, and the substrate must be relatively close to the target.

Handling Insulating Materials

Standard sputtering works best with electrically conductive target materials. To sputter insulating materials, a more complex Radio Frequency (RF) energy source is required instead of a standard DC source.

Matching the Technique to Your Goal

Choosing the right deposition process requires understanding what you are trying to achieve with your material.

- If your primary focus is depositing a complex alloy or a material with a very high melting point: Sputtering is often the superior PVD technique for its precision and ability to handle difficult materials.

- If you are looking for the general category of processes that physically transfer material onto a surface: You are referring to Physical Vapor Deposition (PVD), which includes sputtering, evaporation, and other methods.

- If your process involves a chemical reaction on the substrate's surface to form the film: You are likely looking at Chemical Vapor Deposition (CVD), a different category of thin-film deposition altogether.

Understanding that sputtering is a tool within the PVD toolbox is the first step toward selecting the right process for your specific application.

Summary Table:

| Feature | PVD (Category) | Sputtering (Technique) |

|---|---|---|

| Definition | A family of processes that deposit thin films via physical means. | A specific PVD method that uses plasma to eject target atoms. |

| Mechanism | Converts solid material to vapor physically (e.g., heating, bombardment). | Uses energetic gas ions to knock atoms off a target material. |

| Best For | General thin-film deposition. | High-melting-point materials, complex alloys, and precise control. |

| Key Advantage | Broad applicability. | Excellent composition control for difficult materials. |

Need to select the right deposition technique for your project? The experts at KINTEK are here to help. We specialize in lab equipment and consumables for all your thin-film coating needs. Whether you're working with high-melting-point materials or complex alloys, our team can provide the ideal sputtering or PVD solution to enhance your research and development. Contact us today to discuss your specific application and discover how KINTEK can support your laboratory's success!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells