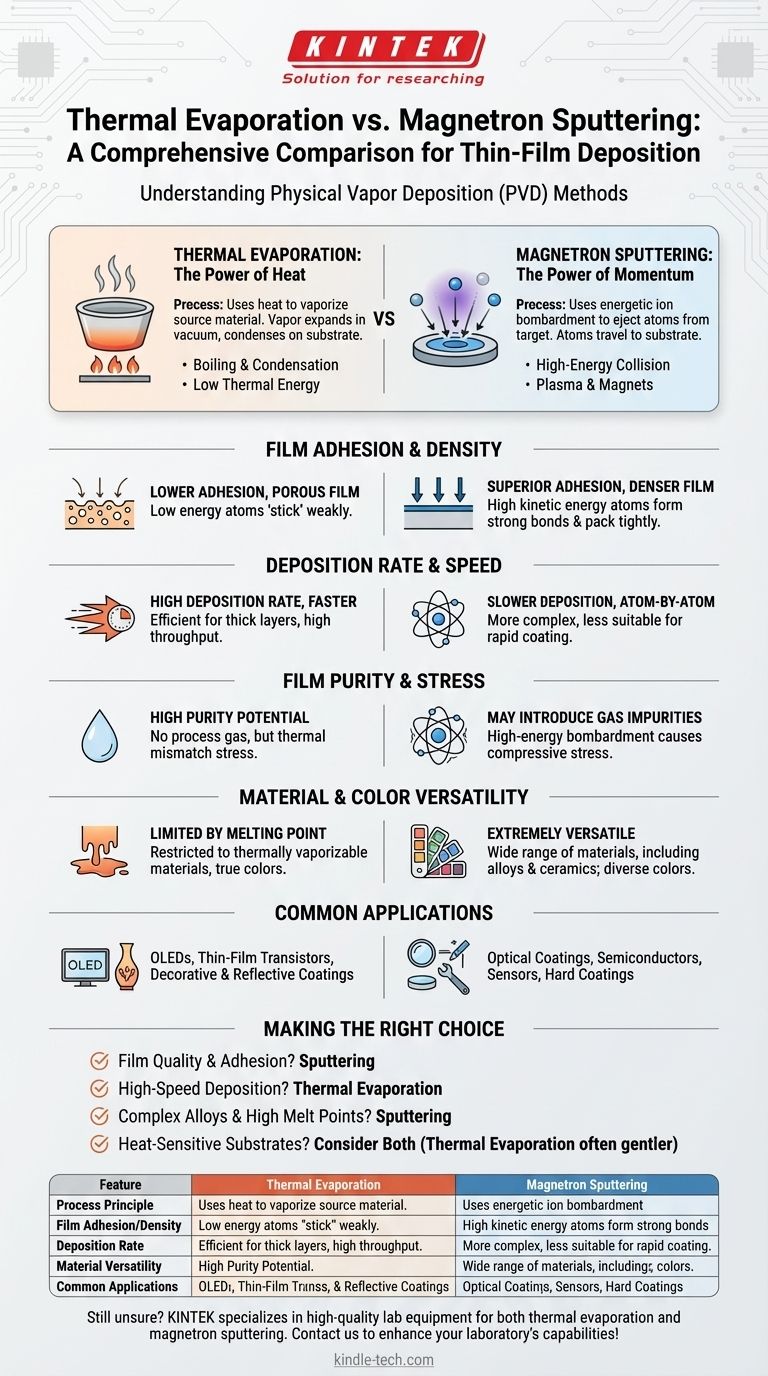

At their core, thermal evaporation and magnetron sputtering are two distinct methods of physical vapor deposition (PVD) that differ in how they transform a solid material into a vapor to coat a substrate. Thermal evaporation uses heat to boil a material until it vaporizes, while magnetron sputtering uses energetic ion bombardment to physically knock atoms off a target. This fundamental difference in energy transfer dictates the properties of the resulting thin film, such as its adhesion, density, and deposition rate.

Choosing between these two techniques is a classic engineering trade-off. Magnetron sputtering generally produces higher-quality, more adhesive films but is a slower and more complex process. Thermal evaporation is faster and simpler but results in films with lower density and weaker adhesion.

The Fundamental Process: Heat vs. Momentum

Both techniques occur in a vacuum chamber to ensure the vaporized material can travel to the substrate without colliding with air molecules. However, the method of generating that vapor is the critical distinction.

How Thermal Evaporation Works

Thermal evaporation is conceptually simple. A source material, typically held in a crucible or "boat," is heated by passing a large electrical current through it until its temperature rises past its vaporization point.

This process creates a vapor cloud of material that expands throughout the vacuum chamber. When this vapor comes into contact with the cooler surface of your substrate, it condenses, forming a thin film. This is analogous to how steam from a boiling kettle condenses on a cold window.

How Magnetron Sputtering Works

Sputtering does not rely on heat. Instead, it uses a high-energy plasma, typically of an inert gas like Argon. A high voltage is applied to the source material (the "target"), causing the gas to ionize and form a glowing plasma.

These positively charged ions are then accelerated into the negatively charged target with immense force. This collision is energetic enough to knock individual atoms or small clusters of atoms off the target material. These "sputtered" atoms travel through the vacuum and deposit onto the substrate, building a film atom by atom. The magnets are used to confine the plasma near the target, dramatically increasing the efficiency of the sputtering process.

Comparing Key Film Properties

The difference in energy—low thermal energy for evaporation versus high kinetic energy for sputtering—directly impacts the final film characteristics.

Film Adhesion and Density

Sputtered atoms arrive at the substrate with significantly higher kinetic energy. This energy helps them form a stronger bond with the substrate surface and pack together more tightly, resulting in superior adhesion and a denser film.

Evaporated atoms have only low thermal energy. They essentially "stick" where they land, leading to a more porous film structure and weaker adhesion to the substrate.

Deposition Rate and Speed

Thermal evaporation can produce a robust vapor stream, enabling very high deposition rates and shorter process times. This makes it highly efficient for depositing thicker layers or for high-throughput manufacturing.

Sputtering is an atom-by-atom process, which is inherently slower. The deposition rates are generally much lower than thermal evaporation, making it less suitable for applications demanding rapid coating.

Film Purity and Stress

Evaporation can produce very pure films for certain materials, as it doesn't require a process gas like argon, which can sometimes become embedded in the sputtered film.

However, both processes can introduce stress. The high-energy bombardment in sputtering can cause compressive stress, while the thermal mismatch between a hot film and a cool substrate during evaporation can cause tensile stress.

Material and Color Versatility

Sputtering is extremely versatile and can be used to deposit almost any material, including metals, ceramics, and complex alloys, because it doesn't rely on melting points. This allows for a wide range of color options by sputtering different materials or introducing reactive gases.

Evaporation is limited to materials that can be thermally vaporized without decomposing. Colors are generally limited to the true color of the source material (e.g., aluminum), and achieving other colors often requires a secondary painting process.

Common Applications for Each Method

The distinct advantages of each technique make them suitable for different applications.

When to Use Thermal Evaporation

This method is preferred when high speed and process simplicity are priorities and supreme film adhesion is not the primary concern.

Common uses include manufacturing OLEDs, thin-film transistors, and creating simple metallic coatings for decorative or reflective purposes.

When to Use Magnetron Sputtering

Sputtering is the go-to choice for applications where film quality, durability, and adhesion are critical.

It is widely used for producing optical coatings (like anti-reflection lenses), hard coatings for tools, and creating the precise electrical contacts and layers found in semiconductors and sensors.

Making the Right Choice for Your Goal

Your decision should be guided by the most critical requirements of your specific project.

- If your primary focus is film quality and adhesion: Sputtering is the superior choice due to the higher energy of the depositing atoms, creating denser and more durable films.

- If your primary focus is high-speed deposition or process simplicity: Thermal evaporation offers significantly faster coating times and involves less complex equipment.

- If you are depositing complex alloys or refractory materials: Sputtering can deposit materials with extremely high melting points or complex compositions that cannot be thermally evaporated.

- If you are working with heat-sensitive substrates: While both methods generate heat, thermal evaporation is often considered gentler, though specific process parameters must be carefully managed in either case.

Understanding the physics that distinguishes these two powerful techniques empowers you to select the optimal deposition method for your specific application.

Summary Table:

| Feature | Thermal Evaporation | Magnetron Sputtering |

|---|---|---|

| Process Principle | Heat-induced vaporization | Energetic ion bombardment (sputtering) |

| Film Adhesion/Density | Lower adhesion, more porous | Superior adhesion, denser films |

| Deposition Rate | High speed, faster coating | Slower, atom-by-atom process |

| Material Versatility | Limited by melting points | Wide range (metals, ceramics, alloys) |

| Common Applications | OLEDs, decorative coatings | Optical coatings, semiconductors, hard coatings |

Still unsure which PVD method is right for your lab's thin-film deposition needs? KINTEK specializes in providing high-quality lab equipment and consumables for both thermal evaporation and magnetron sputtering processes. Our experts can help you select the ideal solution to achieve superior film adhesion, precise thickness control, and optimal material performance for your specific application. Contact us today to discuss your project requirements and discover how KINTEK can enhance your laboratory's capabilities!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

People Also Ask

- What metal can evaporate? A Guide to Vapor Pressure and Thin Film Deposition

- What are the advantages of electron beam evaporation? Achieve High-Purity, High-Rate Thin Films

- What is the source of electron beam evaporation? The Electron Gun Explained for High-Purity Thin Films

- What is the thermal evaporation method of deposition? A Simple Guide to Thin Film Coating

- What is the principle of electron beam deposition? A Guide to High-Speed, Versatile Thin Films

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating

- What is the use of electron beam evaporation? Achieve High-Purity Thin Films for Demanding Applications

- How does the vacuum evaporation system work? A Guide to Thin Film Deposition