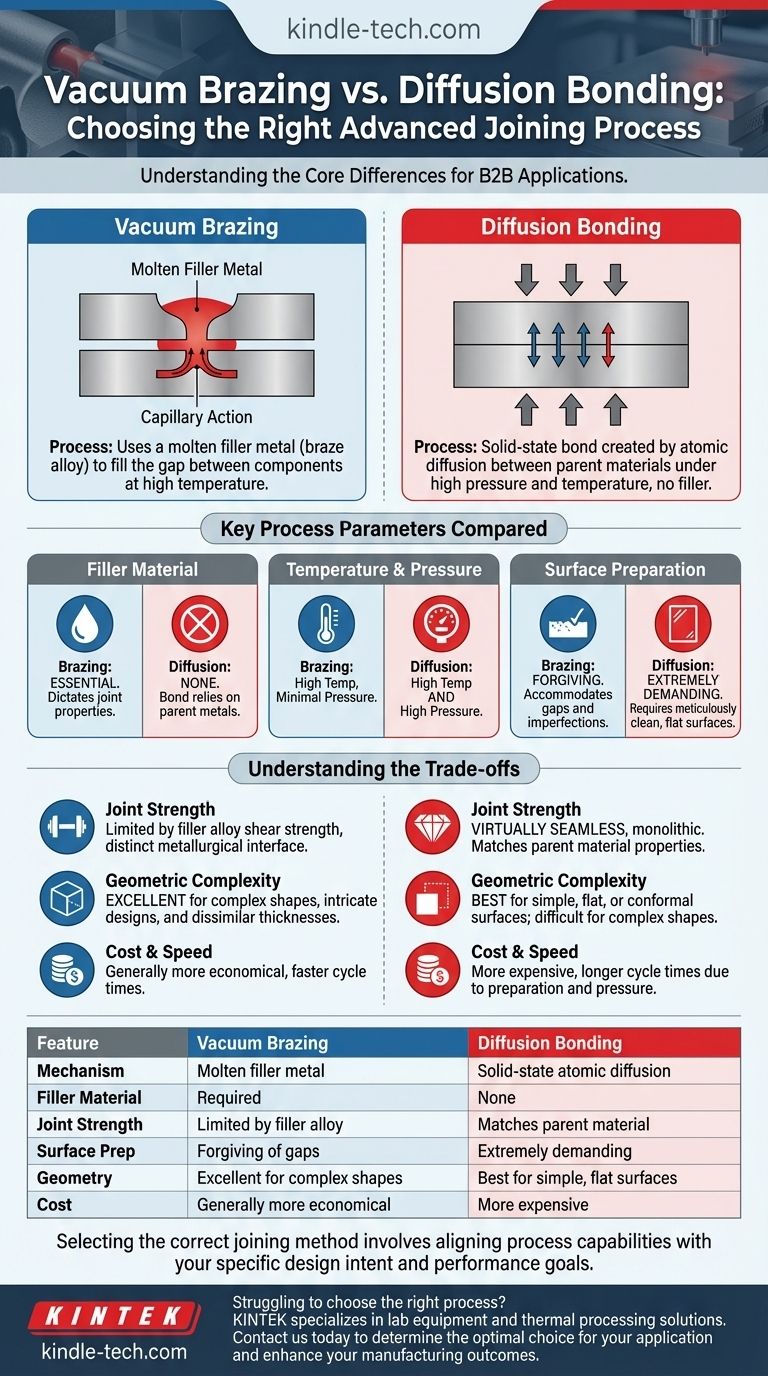

The fundamental difference between vacuum brazing and diffusion bonding lies in how the joint is created. Vacuum brazing uses a molten filler metal to join two components, while diffusion bonding creates a direct, solid-state bond between the parent materials at an atomic level without any filler.

The choice between these two advanced joining techniques is a choice between process practicality and ultimate performance. Brazing offers flexibility for complex geometries by filling a gap, whereas diffusion bonding achieves a seamless, parent-metal-strength bond by eliminating that gap entirely.

Understanding the Core Mechanisms

To select the right process, you must first understand how each one fundamentally works. While both occur under high temperature and vacuum to ensure purity, their methods of creating a bond are entirely distinct.

How Vacuum Brazing Works: The Filler Metal

Vacuum brazing is a process where a filler metal (or braze alloy) with a lower melting point than the base materials is used.

The components are assembled with the filler metal placed in or near the joint. Inside a vacuum furnace, the assembly is heated to a temperature above the filler's melting point but below the base materials' melting point.

The molten filler then flows into the gap between the components via capillary action, creating a strong, permanent metallurgical bond upon cooling.

How Diffusion Bonding Works: The Solid-State Bond

Diffusion bonding is a solid-state joining process that uses no filler material whatsoever. It is a direct bond between the two workpieces.

The components, which must have exceptionally clean and flat surfaces, are brought into intimate contact under high pressure and temperature inside a vacuum.

This environment allows atoms from each component to migrate across the boundary, creating a single, continuous piece of material with a joint that is often indistinguishable from the parent metals.

Key Process Parameters Compared

The operational differences between the two methods have significant implications for design, manufacturing, and final component performance.

The Role of Filler Material

The use of a filler is the most defining difference. In brazing, the filler is essential to the process and its properties dictate the strength and characteristics of the joint.

In diffusion bonding, there is no filler. The bond's properties are determined entirely by the parent materials themselves.

Temperature and Pressure Requirements

Vacuum brazing primarily relies on high temperature to melt the filler alloy, requiring only minimal pressure to hold the parts in place.

Diffusion bonding, by contrast, relies on a combination of high temperature and high pressure. The pressure is critical for forcing the two surfaces into the intimate atomic-level contact needed for diffusion to occur.

Surface Preparation and Tolerances

Vacuum brazing is relatively forgiving of surface imperfections and can accommodate larger, less precise gaps between parts, as the filler metal is designed to fill these voids.

Diffusion bonding is extremely demanding. It requires surfaces that are meticulously cleaned, precisely machined, and often polished to be exceptionally flat and smooth. Any imperfection can create a void and prevent a successful bond.

Understanding the Trade-offs

Choosing a process involves balancing the desired performance with manufacturing complexity and cost. Neither method is universally superior; they are suited to different applications.

Joint Properties and Performance

A diffusion bond is virtually seamless and monolithic. When executed correctly, the joint can exhibit the same mechanical strength and physical properties as the parent material, making it ideal for high-performance applications.

A brazed joint's strength is limited by the shear strength of the filler alloy, which is almost always lower than that of the parent materials. The joint represents a distinct metallurgical interface that can be a point of failure.

Geometric Complexity

Brazing excels at joining complex shapes and assemblies that are difficult to press together uniformly. Its ability to fill gaps makes it a more versatile and practical choice for intricate designs or dissimilar thicknesses.

Diffusion bonding is best suited for parts with simple, flat, or conformal joining surfaces where uniform pressure can be easily applied.

Material Compatibility and Cost

Both processes are excellent for joining dissimilar materials. However, diffusion bonding can sometimes join combinations that are challenging for brazing due to incompatible filler metal reactions.

Generally, the extensive surface preparation and longer cycle times make diffusion bonding a more expensive process than vacuum brazing, especially for components that do not already have tightly toleranced surfaces.

Making the Right Choice for Your Application

Your final decision should be driven by the specific engineering requirements of your component.

- If your primary focus is maximum joint integrity and a seamless interface: Diffusion bonding is the superior choice, as it creates a bond with the properties of the parent metal.

- If your primary focus is joining complex geometries or bridging larger gaps: Vacuum brazing provides the necessary flexibility and is more forgiving of manufacturing tolerances.

- If your primary focus is balancing strong performance with manufacturing cost: Vacuum brazing is often the more practical and economical option for a wide range of applications.

Ultimately, selecting the correct joining method is about aligning the process capabilities with your specific design intent and performance goals.

Summary Table:

| Feature | Vacuum Brazing | Diffusion Bonding |

|---|---|---|

| Mechanism | Uses molten filler metal | Solid-state atomic diffusion |

| Filler Material | Required | None |

| Joint Strength | Limited by filler alloy | Matches parent material |

| Surface Prep | Forgiving of gaps | Extremely demanding |

| Geometry | Excellent for complex shapes | Best for simple, flat surfaces |

| Cost | Generally more economical | More expensive |

Struggling to choose the right joining process for your high-performance components? KINTEK specializes in lab equipment and consumables, serving laboratory needs with advanced thermal processing solutions. Our experts can help you determine whether vacuum brazing or diffusion bonding is the optimal choice for your specific materials, design, and performance goals. Contact us today via our [#ContactForm] to discuss your project and discover how our precision equipment can enhance your manufacturing outcomes.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What functions does the vacuum environment of a vacuum hot pressing furnace serve? Optimize Cu/WC Composite Performance

- How does a vacuum hot press sintering furnace contribute to graphite/copper composites? Key Benefits & Mechanisms

- What function does the vacuum environment serve during the densification of Ag-SnO2-Y2O3? Optimize Material Density

- How does furnace temperature control affect Diamond/Al-Cu composites? Maximize Phase Control and Thermal Performance.

- What is pressure sintering? Achieve High-Density Materials Faster and Stronger