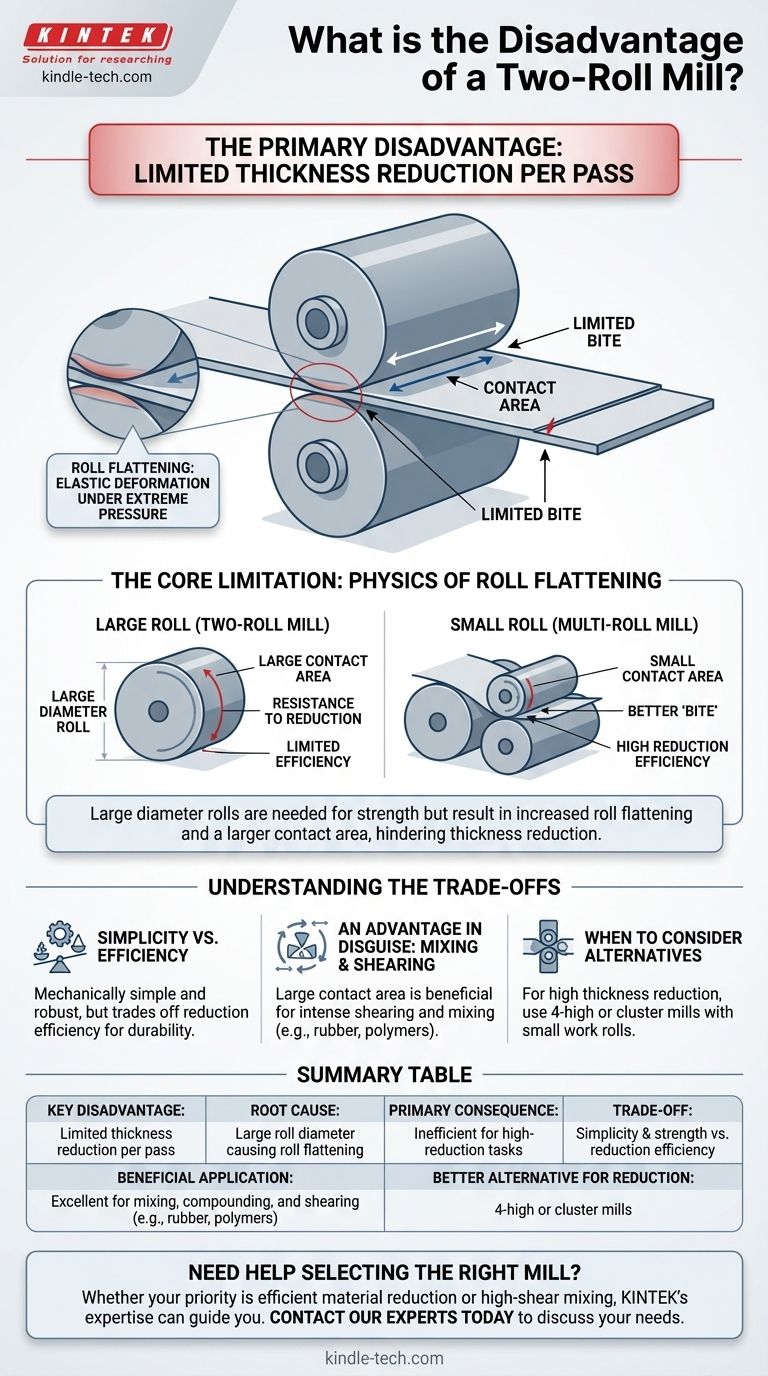

The primary disadvantage of a two-roll mill is its limited ability to significantly reduce the thickness of a material in a single pass. This limitation is a direct consequence of the large diameter of its rolls, which leads to a phenomenon known as roll flattening under the immense pressures required for milling.

The core issue with a two-roll mill is a physical paradox: the large, strong rolls needed to prevent bending under pressure deform slightly, creating a larger contact area that resists the very thickness reduction the mill is designed to achieve.

The Core Limitation: The Physics of Roll Flattening

The defining disadvantage of a two-roll mill stems from a simple principle of physics. Understanding this helps clarify why this design is suited for some tasks but not others.

What is Roll Flattening?

Roll flattening is the elastic deformation of the rolls at the point of contact with the workpiece. Under extreme pressure, the cylindrical roll surface flattens slightly, increasing the surface area that is in contact with the material being processed.

This larger contact area makes it more difficult for the rolls to "bite" into the material and force it through the narrowing gap.

The Role of Roll Diameter

Two-roll mills, also known as 2-high mills, require large-diameter rolls to provide the necessary structural rigidity and strength. This size prevents the rolls from bending or deflecting under the massive separating forces generated during milling.

However, this necessary largeness is also the source of the problem. Larger diameter rolls naturally have a larger contact area with the material, which is then exaggerated by the roll flattening effect.

The Consequence: Limited Reduction

The combination of a large initial contact area and roll flattening results in limited reduction capability. The mill becomes less efficient at thinning the material.

Think of it like trying to press a dough ball flat. Using your wide palm (a large, flat "roll") is less effective at rapidly thinning one specific spot than using the narrow side of your hand (a smaller "roll"). The two-roll mill operates more like the palm.

Understanding the Trade-offs

This limitation does not make the two-roll mill obsolete. Rather, it defines its ideal applications and clarifies its trade-offs against other designs.

Strength and Simplicity vs. Reduction Efficiency

The two-roll mill is mechanically simple, robust, and often more cost-effective than more complex configurations. Its disadvantage in reduction efficiency is a direct trade-off for its structural simplicity and durability.

An Advantage in Disguise: Mixing and Shearing

For many applications, high-efficiency reduction is not the primary goal. The large contact area that limits reduction is actually beneficial for tasks like mixing, blending, and compounding.

Applications in the rubber and polymer industries, such as mixing PVC powder or creating masterbatches, rely on the intense shearing action that occurs over this large contact surface. Here, the "disadvantage" becomes a key processing feature.

When to Consider Alternatives

When a high degree of thickness reduction in a single pass is the priority, other mill designs are superior. Multi-roll configurations like 4-high or cluster mills were invented specifically to overcome roll flattening.

These designs use small-diameter work rolls (for a small contact area) supported by much larger backup rolls to provide the necessary rigidity and prevent bending.

Making the Right Choice for Your Application

Selecting the correct mill configuration depends entirely on your primary processing objective.

- If your primary focus is material mixing, compounding, or shearing: The robust design and large contact area of a two-roll mill make it an effective and reliable choice.

- If your primary focus is significant thickness reduction of metals or other hard materials: The inherent limitations of a two-roll mill mean you should consider a 4-high or cluster mill for better efficiency.

Ultimately, understanding a tool's limitations is the key to using it effectively for the right task.

Summary Table:

| Key Disadvantage | Root Cause | Primary Consequence |

|---|---|---|

| Limited thickness reduction per pass | Large roll diameter causing roll flattening | Inefficient for high-reduction tasks |

| Trade-off | Beneficial Application | Better Alternative for Reduction |

| Simplicity & strength vs. reduction efficiency | Excellent for mixing, compounding, and shearing (e.g., rubber, polymers) | 4-high or cluster mills |

Need help selecting the right mill for your specific application?

Whether your priority is efficient material reduction or high-shear mixing and compounding, KINTEK's expertise in lab equipment can guide you to the optimal solution. Our team can help you understand the trade-offs and select equipment that maximizes your processing efficiency.

Contact our experts today to discuss your needs and find the perfect mill for your lab.

Visual Guide

Related Products

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- Laboratory Single Horizontal Jar Mill

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Jar Mill with Agate Grinding Jar and Balls

People Also Ask

- What are the advantages of screw extruders? Achieve Efficient, Continuous Polymer Processing

- What is short capacity of injection Moulding machine? Optimize Your Shot Size for Flawless Parts

- What is the use of a blown film machine? To Produce Strong, Versatile Plastic Films for Packaging

- What is a two-roll differential speed mill? Achieve Superior Polymer Mixing & Dispersion

- What is the role of high-speed melt mixing equipment? Key to RPE/CSPE Thermoplastic Elastomer Synthesis

- What is the blown film technique? A Guide to High-Strength Plastic Film Production

- What is the screw extrusion process? A Guide to Continuous Plastic Profiling

- What is a two roll mill for rubber compounding? A Foundational Tool for Polymer Processing