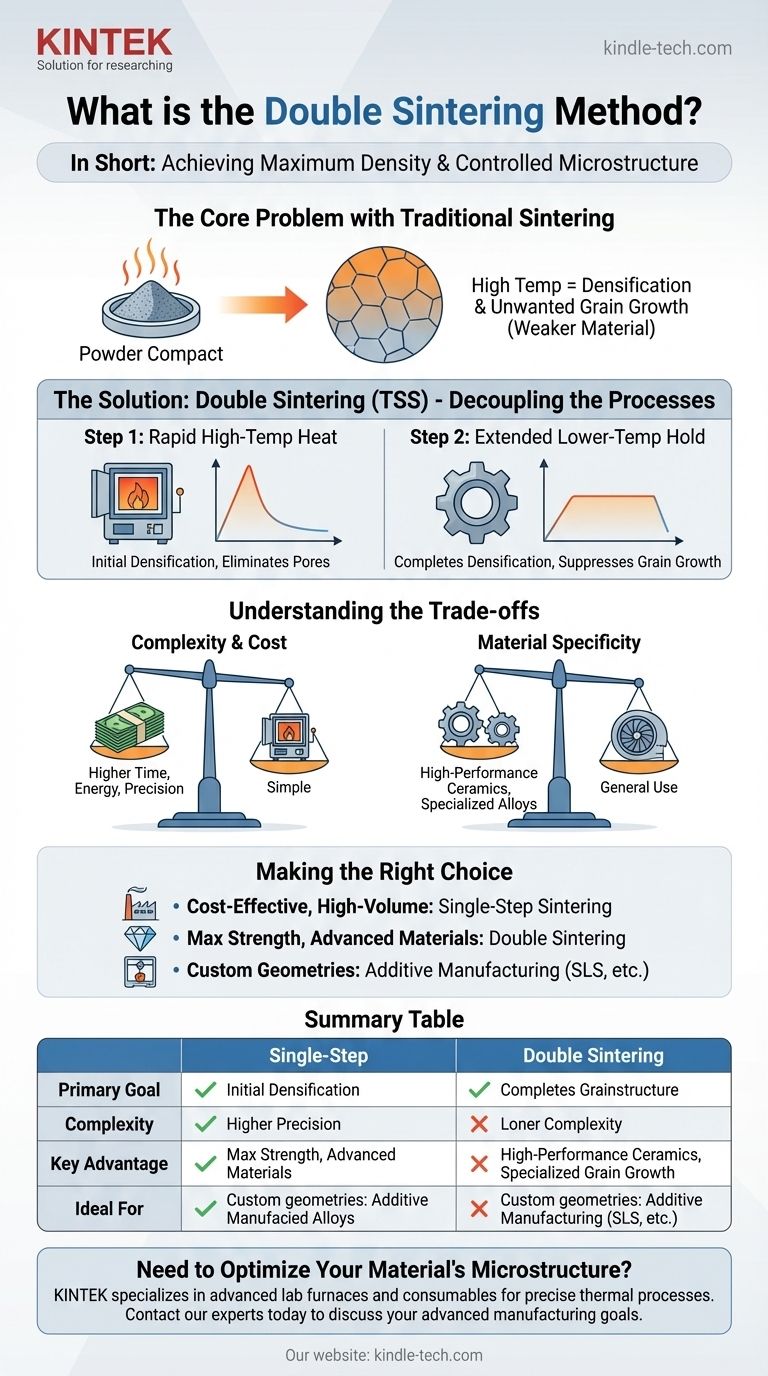

In short, the double sintering method is a specialized thermal process that uses two distinct heating and cooling cycles instead of one. Its primary purpose is to achieve a dense final product while precisely controlling the microstructure, specifically by minimizing the growth of internal grains, which is often a challenge in standard single-sintering processes.

The core problem with traditional sintering is that the high temperatures needed for densification also cause unwanted grain growth, which can weaken the material. Double sintering solves this by decoupling the two phenomena—using a first high-temperature step for initial densification and a second, lower-temperature step to complete densification while suppressing grain growth.

The Fundamentals of Sintering

What Sintering Achieves

Sintering is a manufacturing process that compacts a powdered material into a solid mass using heat and pressure.

The key is that the temperature remains below the material's melting point. This allows the individual particles to fuse at their contact points.

The Standard Single-Step Process

In a typical process, a "green" part is formed by mixing the primary powder with a temporary bonding agent.

When heated, this binder burns away. As the temperature rises further, the powder particles begin to bond, reducing the porous spaces between them and creating a dense, solid object.

This method is highly effective for materials with high melting points, such as metals and ceramics, and is fundamental to powder metallurgy and certain types of 3D printing.

Why a Second Sintering Step is Necessary

The Core Conflict: Densification vs. Grain Growth

The ultimate goal of sintering is to achieve maximum density (i.e., minimal porosity). This requires high temperatures to drive the atomic diffusion that fuses particles together.

However, these same high temperatures also promote grain growth. As small grains merge into larger ones, the material's mechanical properties, like strength and hardness, can degrade significantly.

In a single sintering step, you are forced to make a compromise between achieving high density and preventing excessive grain growth.

The Solution: Decoupling the Processes

The double sintering method, often called two-step sintering (TSS), cleverly separates these two competing processes.

The first step involves heating the material rapidly to a high temperature for a very short time. This kick-starts the densification process, eliminating many of the pores.

The material is then quickly cooled to a slightly lower temperature and held there for an extended period. At this second temperature, the rate of densification remains relatively high, while the rate of grain growth is significantly suppressed.

Understanding the Trade-offs

Process Complexity and Cost

The primary drawback of double sintering is its complexity. It requires precise control over heating and cooling rates, which demands more sophisticated furnace equipment.

This added step and the need for precision increase both the time and energy consumption of the process, making it more expensive than conventional single-step sintering.

Material and Application Specificity

Double sintering is not a universal solution. Its effectiveness is highly dependent on the specific material system being used.

It is most commonly applied to high-performance ceramics or specialized metal alloys where achieving a fine-grained, fully dense microstructure is critical for the final application's performance—and worth the extra cost.

Making the Right Choice for Your Goal

- If your primary focus is cost-effective, high-volume production: Standard single-step sintering is almost always the more practical and economical choice.

- If your primary focus is achieving maximum mechanical strength in advanced materials: Double sintering offers superior control over the final microstructure and is a powerful tool for high-performance applications.

- If your primary focus is creating custom geometries via additive manufacturing: Techniques like Selective Laser Sintering (SLS) use a different layer-by-layer approach, but the underlying goal of fusing powder while managing heat remains a core principle.

Ultimately, choosing a sintering method requires balancing the desired material properties against the constraints of cost, time, and manufacturing complexity.

Summary Table:

| Aspect | Single-Step Sintering | Double Sintering |

|---|---|---|

| Primary Goal | Cost-effective, high-volume production | Maximum density with controlled grain size |

| Process Complexity | Lower | Higher (requires precise temperature control) |

| Key Advantage | Simplicity and speed | Superior final material properties (strength, hardness) |

| Ideal For | General applications | High-performance ceramics and specialized alloys |

Need to optimize your material's microstructure? The double sintering method is a sophisticated solution for achieving maximum density and strength in high-performance applications. KINTEK specializes in providing the advanced lab furnaces and consumables required for precise thermal processes like this. Contact our experts today to discuss how we can support your advanced material manufacturing goals.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the function of quartz tubes and vacuum sealing systems? Secure Your High-Purity Solid Solution Synthesis

- What is the primary function of quartz tubes in halide electrolyte synthesis? Ensure Purity & Precise Stoichiometry

- What are the primary functions of high-precision tube furnaces in graphene growth? Achieve Defect-Free GS Synthesis

- How does an industrial tube furnace ensure the required process conditions for supercritical fluid experimental devices?

- What happens when quartz is heated? A Guide to Its Critical Phase Transitions and Uses