In manufacturing, the dry bag process is a form of isostatic pressing used to compact powdered materials into a solid, uniform mass. Unlike its "wet bag" counterpart, the key feature of the dry bag method is that the flexible mold containing the powder is permanently installed within the pressure vessel and does not come into direct contact with the pressurizing fluid. This containment makes the process significantly faster, cleaner, and more suitable for automation.

The core principle to understand is that the dry bag process trades the shape flexibility of other methods for immense gains in speed and automation. It is a specialized technique engineered specifically for the high-volume production of relatively simple components.

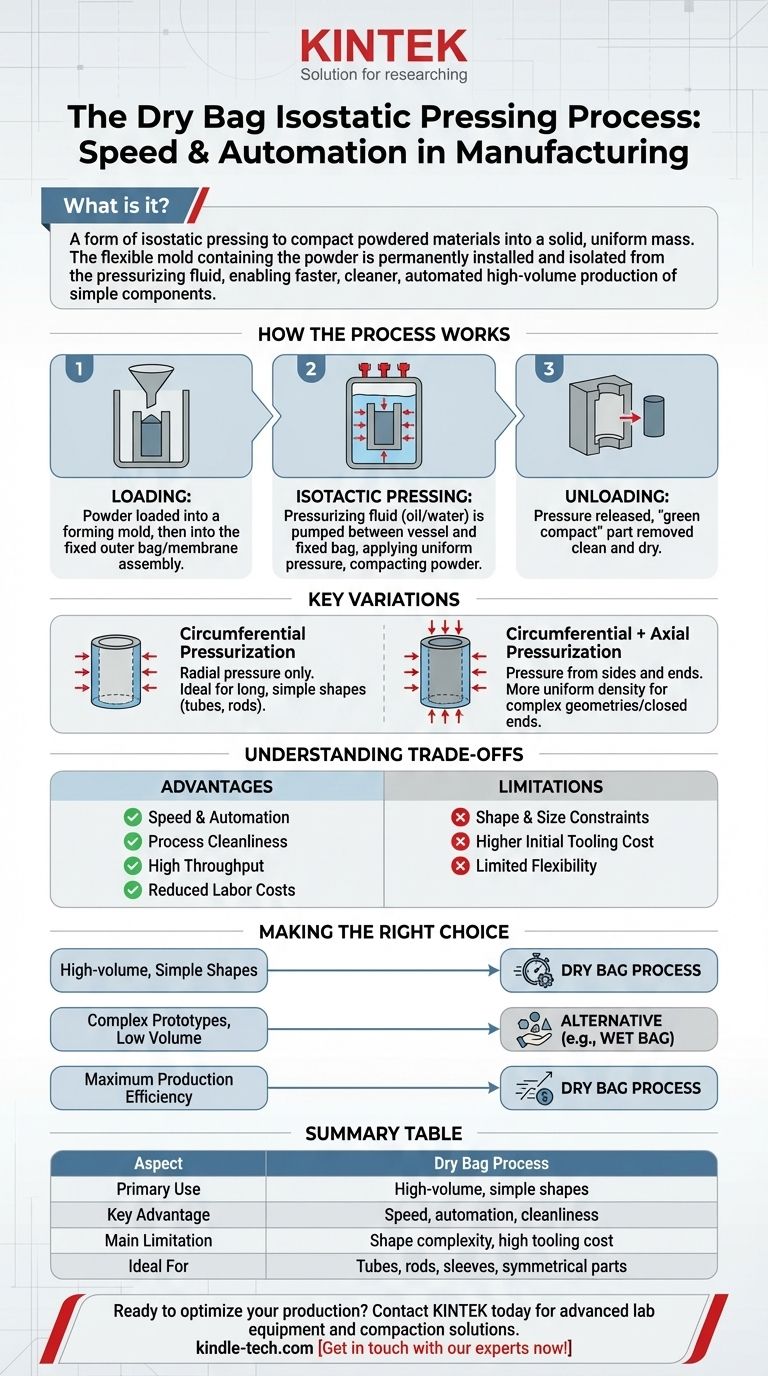

How the Dry Bag Process Works

The dry bag method is defined by its unique tooling arrangement, which isolates the material from the pressurizing medium. This design is central to its efficiency.

The Fixed Mold Assembly

At the heart of a dry bag press is a durable, flexible membrane or "bag" that is fixed inside the steel pressure vessel. This outer bag remains in the vessel during the entire production cycle and acts as a barrier.

Loading the Powder

Powder is introduced into a separate, often disposable, forming mold. This filled mold is then loaded into the permanent outer bag. Alternatively, for fully automated systems, a hopper can feed the powder directly into the fixed bag assembly.

Applying Isostatic Pressure

Once the powder is loaded and the vessel is sealed, a liquid (typically oil or water) is pumped into the space between the pressure vessel wall and the fixed outer bag. This fluid applies uniform, or isostatic, pressure from all sides, compacting the powder within the inner mold into a solid, high-density part known as a "green compact."

Key Variations of the Dry Bag Method

The way pressure is applied can be tailored to the geometry of the part being produced. This leads to two primary system designs.

Circumferential Pressurization

This is the simpler of the two systems. It uses a cylindrical pressing mold that applies pressure only from the outer radial surfaces. This method is ideal for producing long, simple shapes like tubes, rods, and sleeves.

Circumferential + Axial Pressurization

This more advanced system applies pressure from the outer surfaces and from the top (and sometimes bottom) of the mold. This axial pressure helps achieve more uniform density throughout the part, especially for components with closed ends or more complex geometries than a simple tube.

Understanding the Primary Trade-offs

The decision to use the dry bag process hinges on a clear understanding of its strengths and limitations. It is a highly specialized tool, not a universal solution.

Advantage: Speed and Automation

Because the mold assembly is fixed and the process is self-contained, dry bag pressing is exceptionally fast and easily automated. This makes it the preferred method for mass production, enabling high throughput and reducing labor costs.

Advantage: Process Cleanliness

Since the forming mold and the powder never touch the pressurizing liquid, the parts emerge clean and dry. This eliminates the post-processing cleaning steps required in wet bag pressing, further streamlining the production line.

Limitation: Shape and Size Constraints

The primary drawback is a lack of flexibility. The dry bag process is best suited for producing a limited variety of simple, symmetrical shapes. It is not practical for creating large, intricate, or one-off components.

Limitation: Higher Initial Tooling Cost

Developing the robust, permanent mold assembly for an automated dry bag system represents a significant upfront investment compared to the simpler tooling used in wet bag pressing. This cost is only justified by high production volumes.

Making the Right Choice for Your Goal

Selecting the correct pressing method is critical to achieving your manufacturing objectives efficiently. Your production volume and part complexity are the deciding factors.

- If your primary focus is high-volume production of simple shapes: The dry bag process is the definitive choice for its unmatched speed, consistency, and potential for automation.

- If your primary focus is creating complex prototypes or low-volume parts: An alternative like wet bag isostatic pressing offers far greater flexibility in shape and is more cost-effective for smaller runs.

- If your primary focus is achieving maximum production efficiency: The streamlined, automated nature of the dry bag method minimizes manual handling and secondary operations, delivering the lowest cost-per-part at scale.

By understanding its specific strengths in automation and speed, you can leverage the dry bag process to achieve highly efficient and consistent manufacturing outcomes.

Summary Table:

| Aspect | Dry Bag Process |

|---|---|

| Primary Use | High-volume production of simple shapes |

| Key Advantage | Speed, automation, and cleanliness |

| Main Limitation | Shape complexity and higher initial tooling cost |

| Ideal For | Tubes, rods, sleeves, and other symmetrical parts |

Ready to optimize your production line with high-speed isostatic pressing?

At KINTEK, we specialize in providing advanced lab equipment and consumables, including solutions for efficient powder compaction. Our expertise can help you determine if the dry bag process is the right fit for your high-volume manufacturing needs.

Contact us today to discuss how our solutions can bring speed, consistency, and automation to your laboratory or production facility.

Get in touch with our experts now!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- Why is a cold isostatic press (CIP) required after uniaxial pressing? Maximize LLZO Density & Performance

- What will happen if forging is carried out at very low temperature? Discover the Power of Cold Forging

- Why is a cold isostatic press advantageous for Argyrodite sulfide solid-state batteries? Achieve Optimal Densification

- Why Use an Isostatic or High-Precision Hydraulic Press for Li/LLZO/Li Batteries? Master Solid-State Interfaces

- Why is cold working better than hot working? A Guide to Choosing the Right Metal Forming Process

- Why is semi-isostatic pressing used for ceramics? Unlock Uniform Density and Superior Precision

- What products are made from cold isostatic pressing? Achieve Uniform Density in Complex Parts

- Why use cold pressing for Li10SnP2S12 electrolyte pellets? Preserving Stability in Sulfide Electrolytes