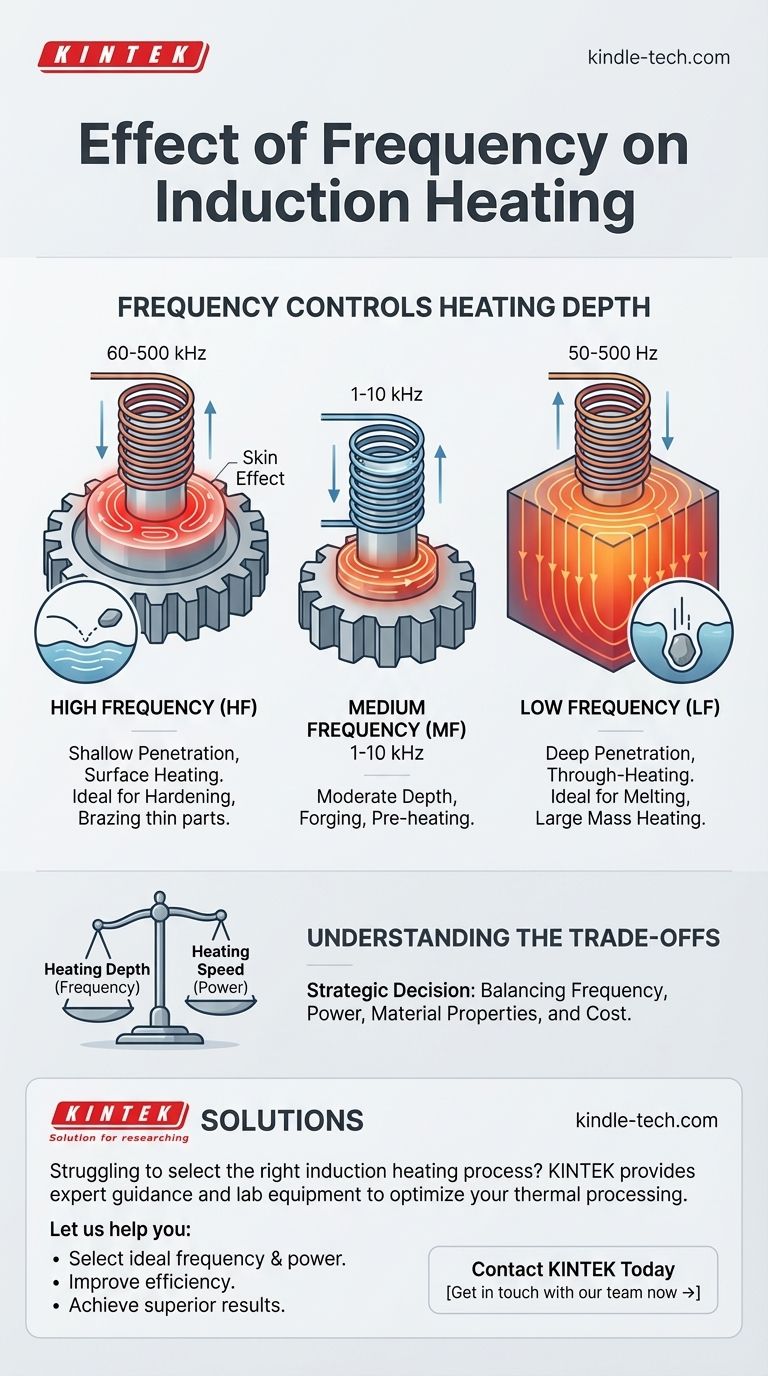

In induction heating, frequency is the primary control for heating depth. A higher frequency concentrates the heating effect near the surface of the workpiece, a phenomenon known as the "skin effect." Conversely, a lower frequency allows the induced energy to penetrate deeper into the material, resulting in more uniform, through-heating. This relationship is fundamental to selecting the right process for your specific application.

While frequency directly controls how deep the heat penetrates, selecting the right induction process is rarely about frequency alone. It is a strategic decision that balances the desired heating depth (frequency) with the required heating speed (power) and the material's properties.

The Fundamental Principle: Frequency and the Skin Effect

To understand the role of frequency, we must first look at the core physics of induction. The process works by inducing electrical currents within the material itself, which in turn generates heat.

How Induction Heating Works

An induction system uses a coil to generate a powerful, rapidly alternating magnetic field. When an electrically conductive part (like a steel gear) is placed within this field, it induces swirling electrical currents inside the part. These are called eddy currents. The material's natural resistance to the flow of these currents generates immense, precise heat through a process called Joule heating.

Introducing the "Skin Effect"

The frequency of the alternating magnetic field dictates where these eddy currents flow. At high frequencies, the currents are forced to flow in a thin layer near the part's surface. This is the skin effect.

Think of it like skipping a stone on water. A very fast, high-frequency spin will cause the stone to skip across the surface. A slow, low-frequency toss will cause the stone to sink and penetrate deep into the water. The same principle applies to eddy currents in a conductor.

The Rule of Thumb: Frequency vs. Penetration Depth

The relationship is simple and inverse:

- Higher Frequency = Shallower Current Penetration = Surface Heating

- Lower Frequency = Deeper Current Penetration = Through-Heating

This control over heating depth is the most critical function of frequency in any induction application.

Practical Applications of Different Frequencies

The choice of frequency is dictated entirely by the engineering goal. Different frequency ranges are optimized for different industrial processes.

High Frequency (HF): For Surface Treatments

Typically operating from 60 kHz to 500 kHz, high-frequency induction is ideal for applications where only the surface needs to be heated. The shallow heating depth is perfect for case hardening gears, shafts, and other components where a hard, wear-resistant surface is needed over a tough, ductile core.

Medium Frequency (MF): For Through-Heating and Forging

This range is used for heating smaller parts all the way through or for pre-heating larger parts for forging or forming. The deeper heat penetration ensures the entire cross-section of the component reaches the target temperature.

Low Frequency (LF): For Large Mass Heating

Used for massive workpieces, such as large billets or slabs, low-frequency induction provides the deep penetration necessary to heat a large volume of metal uniformly. It is also the frequency of choice for melting applications in induction furnaces.

Understanding the Trade-offs

Selecting a frequency is not a purely academic exercise. It involves balancing several practical and economic factors to find the optimal solution.

Frequency vs. Power

Frequency and power are independent but related variables. You can achieve a similar heating outcome with different combinations. For example, a lower-power, high-frequency unit might heat a surface just as effectively as a higher-power, medium-frequency unit, but it might take longer. The choice often comes down to cycle time requirements versus equipment cost.

The Impact of Material

The material of the workpiece is a critical factor. Magnetic materials like carbon steel heat much more easily below their Curie temperature (the point at which they become non-magnetic) than non-magnetic materials like aluminum or copper. The optimal frequency will change based on the material's resistivity and magnetic permeability.

Cost and Equipment Complexity

There is no single machine that does everything perfectly. High-frequency power supplies often use different internal components than low-frequency supplies. The decision must therefore account for the purchase cost, efficiency, and maintenance profile of the equipment best suited for your primary application.

Making the Right Choice for Your Goal

Ultimately, the correct frequency is the one that best matches your desired outcome. Use your process goal as your guide.

- If your primary focus is surface hardening or brazing thin parts: A higher frequency is almost always the correct choice to concentrate energy on the surface.

- If your primary focus is heating a component uniformly for forging: A medium frequency provides the balance of penetration depth and efficient heating time.

- If your primary focus is melting a large volume of metal or heating a very thick slab: A low frequency is necessary to ensure the energy penetrates deep into the mass.

Armed with this understanding, you can now select a process based not just on frequency, but on the precise outcome you need to achieve.

Summary Table:

| Frequency Range | Primary Application | Heating Depth |

|---|---|---|

| High (60-500 kHz) | Surface Hardening, Brazing | Shallow (Surface) |

| Medium (1-10 kHz) | Through-Heating, Forging | Moderate |

| Low (50-500 Hz) | Melting, Large Mass Heating | Deep (Uniform) |

Struggling to select the right induction heating process for your materials?

The choice of frequency is critical to achieving your desired outcome, whether it's precise surface hardening or uniform through-heating. At KINTEK, we specialize in providing the lab equipment and expert guidance to optimize your thermal processing.

We can help you:

- Select the ideal frequency and power for your specific material and application.

- Improve efficiency and consistency in your heating processes.

- Achieve superior results in hardening, brazing, forging, or melting.

Contact KINTEK today for a consultation, and let our experts help you harness the power of induction heating.

Get in touch with our team now →

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Non Consumable Vacuum Arc Induction Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

People Also Ask

- How does a vacuum hot pressing furnace facilitate the consolidation of (Cu–10Zn)-Al2O3 nanocomposites?

- What are the advantages of a vacuum hot-press furnace? Superior Bonding for Diamond/Aluminum Composites

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- What are the advantages of using a vacuum hot press for CuCr50? Achieve Superior Density & Purity in Alloy Production