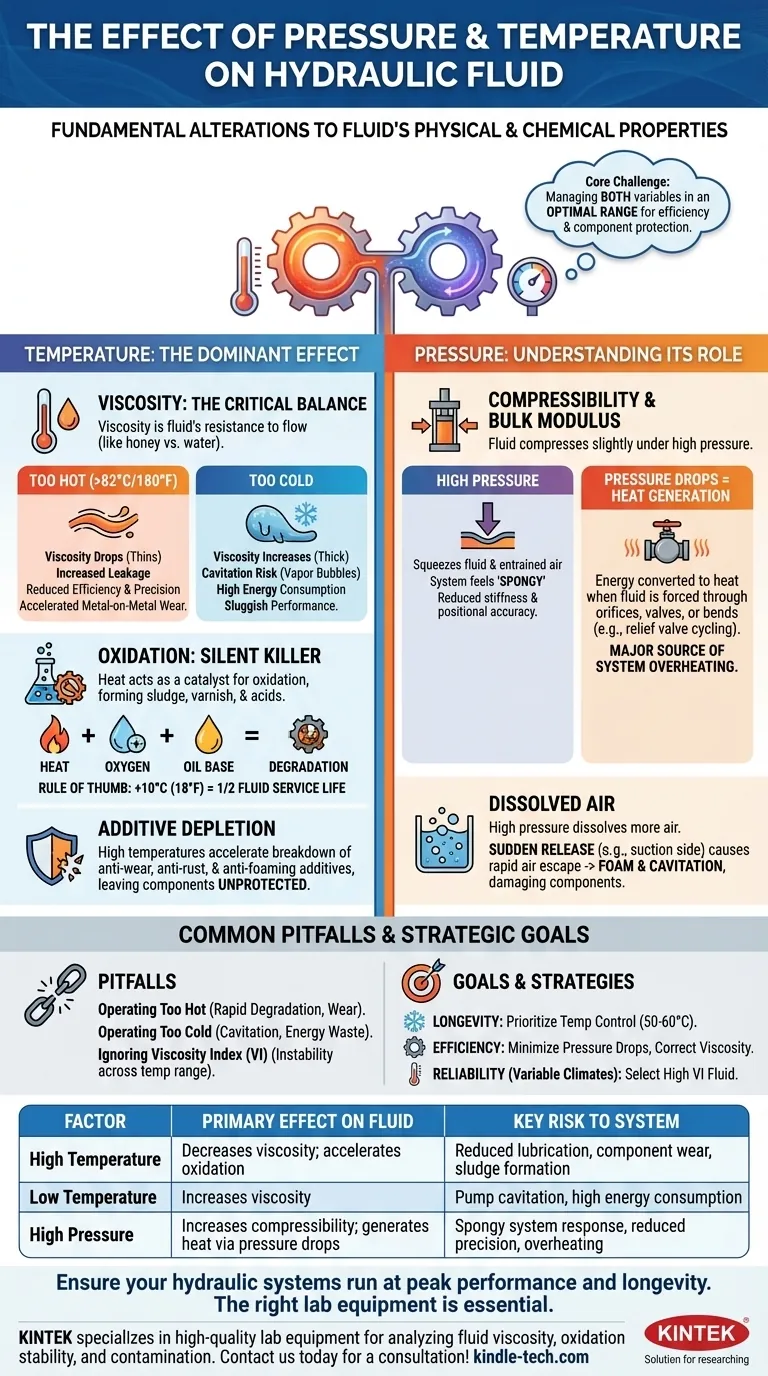

In short, temperature and pressure fundamentally alter a hydraulic fluid's physical and chemical properties. Temperature has the most significant impact, primarily by changing the fluid's viscosity (its thickness) and accelerating its chemical breakdown. Pressure affects the fluid's compressibility and viscosity to a lesser degree but is the primary driver of heat generation within the system.

The core challenge in any hydraulic system is not managing temperature or pressure in isolation, but understanding how they work together. Your fluid's ability to transmit power efficiently and protect components is entirely dependent on keeping both variables within a specific, optimal range.

The Dominant Effect of Temperature

Temperature is the single most critical factor influencing a hydraulic fluid's performance and lifespan. Both excessive heat and cold create distinct operational problems.

Viscosity: The Critical Balancing Act

Viscosity is a fluid's resistance to flow. Think of the difference between pouring honey (high viscosity) and water (low viscosity). The ideal hydraulic fluid has a specific viscosity to do its job correctly.

Temperature directly attacks this balance. When the fluid gets too hot, its viscosity drops. This thinning effect leads to increased internal leakage in pumps and valves, reducing system efficiency and precision. More critically, a thin fluid film cannot properly lubricate moving parts, leading to accelerated metal-on-metal wear.

Conversely, when the fluid is too cold, its viscosity increases dramatically. This thick, sluggish fluid is difficult for the pump to draw from the reservoir, which can lead to cavitation—the formation of damaging vapor bubbles. It also increases energy consumption as the pump works harder to push the fluid through the system.

Oxidation: The Silent Killer of Fluid Life

Heat acts as a catalyst for oxidation, a chemical reaction between the fluid's oil base and oxygen. This process is the primary cause of fluid degradation.

As fluid oxidizes, it forms sludge, varnish, and corrosive acids. Sludge clogs filters and small orifices, while varnish can cause valves to stick. This breakdown permanently degrades the fluid, and as a rule of thumb, for every 18°F (10°C) increase above 140°F (60°C), the fluid's service life is cut in half.

Additive Depletion

Hydraulic fluids contain a package of crucial additives for anti-wear, anti-rust, and anti-foaming properties. High temperatures accelerate the breakdown and depletion of these additives, leaving your system’s components unprotected.

Understanding the Role of Pressure

While temperature alters the fluid itself, pressure is more about what the system does to the fluid and how the fluid responds.

Compressibility and Bulk Modulus

Hydraulic fluid is often considered incompressible, but it does compress slightly under pressure. The measure of a fluid's resistance to compression is its bulk modulus.

High pressure squeezes the fluid, and any entrained air within it, making the system feel "spongy" and reducing its stiffness and positional accuracy. In high-precision applications, this compressibility can significantly affect performance.

The Link Between Pressure Drops and Heat

Pressure itself doesn't create heat, but pressure drops do. Every time fluid is forced through an orifice, valve, or bend in a pipe, hydraulic energy is converted directly into heat.

A relief valve cycling constantly, for example, is a major source of heat. This is the most common way systems overheat—not from external sources, but from their own internal inefficiencies generating heat from pressure changes.

Dissolved Air

Pressure affects how much air can be dissolved in the fluid. At high pressure, more air dissolves. When that pressure is suddenly released (like on the suction side of a pump), the air can rapidly come out of solution, creating foam and contributing to cavitation, which damages components.

Common Pitfalls and Trade-offs

Understanding these principles helps you avoid common operational failures. The goal is to maintain the fluid within its designed operating window.

Operating Too Hot: Accelerated Wear and Failure

Running a system consistently above 180°F (82°C) is a recipe for premature failure. You will experience rapid fluid degradation, seal hardening, and catastrophic component wear due to inadequate lubrication from low-viscosity fluid.

Operating Too Cold: Sluggish Performance and Cavitation

Attempting to run a system at full load with cold, thick fluid can starve the pump, causing cavitation that erodes internal components. The high viscosity also leads to high pressure drops and wasted energy until the system warms up.

Ignoring the Viscosity Index (VI)

The Viscosity Index (VI) measures how much a fluid's viscosity changes with temperature. A fluid with a high VI is more stable, maintaining its viscosity better across a wide temperature range. Choosing a fluid with the wrong VI for your operating environment can lead to either excessive thinning in the heat or excessive thickening in the cold.

Making the Right Choice for Your Goal

Your strategy for managing fluid properties depends entirely on your system's primary objective.

- If your primary focus is maximum system longevity: Prioritize temperature control. Maintain a stable operating temperature between 120-140°F (50-60°C) using properly sized coolers and reservoirs to dramatically slow fluid oxidation and extend component life.

- If your primary focus is peak efficiency: Minimize unnecessary pressure drops. Ensure your system design is efficient, valves are set correctly, and you are using a fluid with the correct viscosity for your steady-state operating temperature.

- If your primary focus is reliability in variable climates: Select a high Viscosity Index (VI) fluid. This ensures the fluid provides adequate protection when hot and doesn't become too thick to pump when cold, requiring less warm-up time.

Ultimately, treating your hydraulic fluid as a critical component—not just a commodity—is the key to a reliable and efficient system.

Summary Table:

| Factor | Primary Effect on Fluid | Key Risk to System |

|---|---|---|

| High Temperature | Decreases viscosity; accelerates oxidation | Reduced lubrication, component wear, sludge formation |

| Low Temperature | Increases viscosity | Pump cavitation, high energy consumption |

| High Pressure | Increases compressibility; generates heat via pressure drops | Spongy system response, reduced precision, overheating |

Ensure your hydraulic systems run at peak performance and longevity. The right lab equipment is essential for monitoring and maintaining your hydraulic fluid's properties. KINTEK specializes in high-quality lab equipment and consumables for analyzing fluid viscosity, oxidation stability, and contamination. Let our experts help you select the perfect tools to protect your investment and optimize your operations. Contact us today for a consultation!

Visual Guide

Related Products

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Lab Heat Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why is a laboratory hydraulic press used for Li3V2(PO4)3 pellets? Optimize Solid-State Sintering for Li-ion Materials

- What are the advantages of using a laboratory manual hydraulic pellet press for FTIR? Enhance Your Spectral Data

- What is the significance of applying 200 MPa of pressure with a laboratory hydraulic pellet press for composite ceramics?

- What is the role of a laboratory hydraulic press in Rare Earth Element (REE) analysis? Unlock High-Precision XRF & LIBS

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy