At its core, pressure primarily changes the volume of hydraulic fluid by a small but significant amount. While hydraulic fluid is treated as incompressible for basic calculations, it does compress in reality, and this effect becomes critical in high-performance and high-pressure applications. This compression stores energy within the fluid, which can impact system performance, efficiency, and safety.

The central takeaway is that hydraulic fluid is not truly incompressible. Understanding its slight compressibility, defined by the Bulk Modulus, is the key to moving beyond basic hydraulic principles and into expert-level design, analysis, and troubleshooting of modern systems.

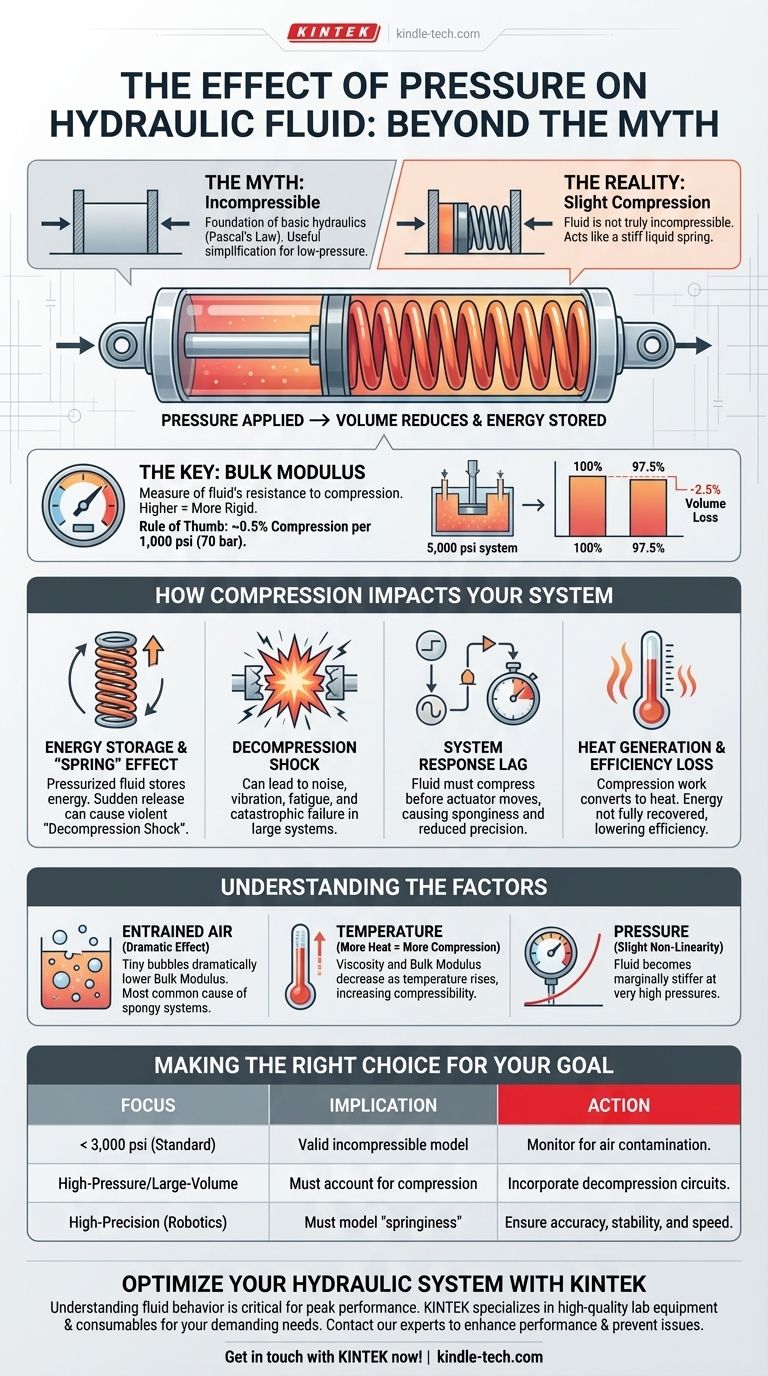

The Myth of Incompressibility

For decades, the foundation of hydraulics has been Pascal's Law, which operates on the assumption that a force applied to a confined fluid is transmitted equally throughout. This works because oil is remarkably resistant to compression, but it is not immune.

The Practical Assumption

In many low-to-medium pressure systems, treating the fluid as perfectly incompressible is a valid and useful simplification. It allows for straightforward calculations of force and speed without significant error. This assumption holds true when precision and energy efficiency are not the absolute top priorities.

The Physical Reality: Bulk Modulus

The true resistance of a fluid to compression is measured by its Bulk Modulus. This value quantifies how much pressure is needed to cause a certain fractional decrease in volume. A higher Bulk Modulus means the fluid is less compressible and more rigid. For example, steel has an extremely high Bulk Modulus, while air has a very low one.

Quantifying the Compression

As a rule of thumb, a typical mineral-based hydraulic oil will compress by approximately 0.5% for every 1,000 psi (70 bar) of pressure applied. While this seems minor, in a 5,000 psi system, the fluid has already lost 2.5% of its original volume. In large or high-precision systems, this volume change is far from negligible.

How Fluid Compression Impacts Your System

Ignoring this small percentage of compression can lead to significant, and often unexpected, consequences in a hydraulic system's behavior. The compressed fluid essentially acts like a stiff liquid spring.

Energy Storage and The "Spring" Effect

When you pressurize hydraulic fluid, you are storing potential energy in it. This stored energy must go somewhere when the pressure is released. A sudden release, like shifting a valve, can cause this energy to be unleashed violently, resulting in decompression shock. This shockwave can cause noise, component fatigue, and even catastrophic failure in high-pressure or large-volume systems.

System Response and Accuracy

Because the fluid must first be compressed before it can move an actuator, there is an inherent delay or "sponginess" in the system's response. In applications requiring high precision, such as CNC machinery or aircraft flight controls, this slight lag can impact accuracy and stability, causing overshoots or oscillations.

Heat Generation and Efficiency Loss

The work done to compress the fluid is converted into internal energy (heat). When the fluid later expands, not all of this energy is recovered as useful work. Some of it is lost as waste heat, which lowers the overall efficiency of the hydraulic system. Over a cycle, this constant compression and decompression contributes to the system's operating temperature.

Understanding the Factors at Play

The degree to which a fluid compresses is not static. It is influenced by the operating conditions and the health of the fluid itself.

The Critical Role of Entrained Air

This is the most dramatic factor. Air is vastly more compressible than oil. Even a tiny amount of entrained air (air bubbles suspended in the fluid) will dramatically lower the effective Bulk Modulus of the fluid. This is the most common cause of a "spongy" or sluggish hydraulic system and is often mistaken for normal fluid compression.

The Influence of Temperature

Generally, as hydraulic fluid heats up, its viscosity and Bulk Modulus decrease. This means a hotter fluid is slightly more compressible than a colder fluid, which can affect system performance during warm-up or under heavy load.

The Effect of Pressure

The Bulk Modulus of hydraulic oil is not perfectly linear. It tends to increase slightly at very high pressures, meaning the fluid becomes marginally stiffer and less compressible as pressure rises. However, for most engineering purposes, it is treated as a constant.

Making the Right Choice for Your Goal

Understanding how to apply this knowledge depends entirely on the demands of your specific hydraulic system.

- If your primary focus is standard industrial machinery (< 3,000 psi): You can generally rely on the incompressible fluid model for basic design, but must remain vigilant for the effects of air contamination, which will always degrade performance.

- If your primary focus is high-pressure or large-volume equipment (e.g., large presses): You must account for fluid compression to calculate volumes accurately and incorporate controlled decompression circuits to prevent equipment damage from energy shock.

- If your primary focus is high-precision or high-response systems (e.g., robotics, aerospace): You must model the fluid's "springiness" and resulting delays to ensure the system meets its targets for accuracy, stability, and speed.

Ultimately, recognizing that hydraulic fluid is a spring, however stiff, is what separates a basic technician from an expert system designer.

Summary Table:

| Pressure Effect | Key Consequence |

|---|---|

| Volume Compression (~0.5% per 1,000 psi) | Energy storage, 'spring' effect |

| Decompression Shock | Potential for noise, vibration, and damage |

| System Response Lag | Reduced precision and stability in controls |

| Heat Generation | Lowered overall system efficiency |

Optimize Your Hydraulic System Performance with KINTEK

Understanding the precise behavior of hydraulic fluids under pressure is critical for achieving peak efficiency, accuracy, and safety in your laboratory or industrial equipment. Whether you're working with high-pressure presses, precision robotics, or standard machinery, the right tools and consumables are essential.

KINTEK specializes in high-quality lab equipment and consumables that meet the demanding needs of modern hydraulic systems. We help our customers ensure reliability and precision in their operations.

Contact our experts today to discuss how our solutions can enhance your system's performance and prevent issues related to fluid compression. Let's work together to achieve your goals.

Visual Guide

Related Products

- Variable Speed Peristaltic Pump

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is the KBr method of IR? Master Solid Sample Analysis for High-Quality Spectra

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production

- What is the industrial significance of laboratory pressure molding equipment for oxide-coated iron powder particles?

- How does a laboratory hydraulic press ensure process consistency? Achieve Reliable CR2032 Coin Cell Assembly

- Is compression molding a fast process? A Guide to Faster Time-to-Market for Low-Volume Production

- What is the XRF method of sampling? Achieve Accurate Elemental Analysis with Proper Sample Prep

- Why is a laboratory hydraulic press used for solid-state battery assembly? Achieve High-Pressure Densification

- What products are made by roll forming? Discover the Versatile Applications Across Industries