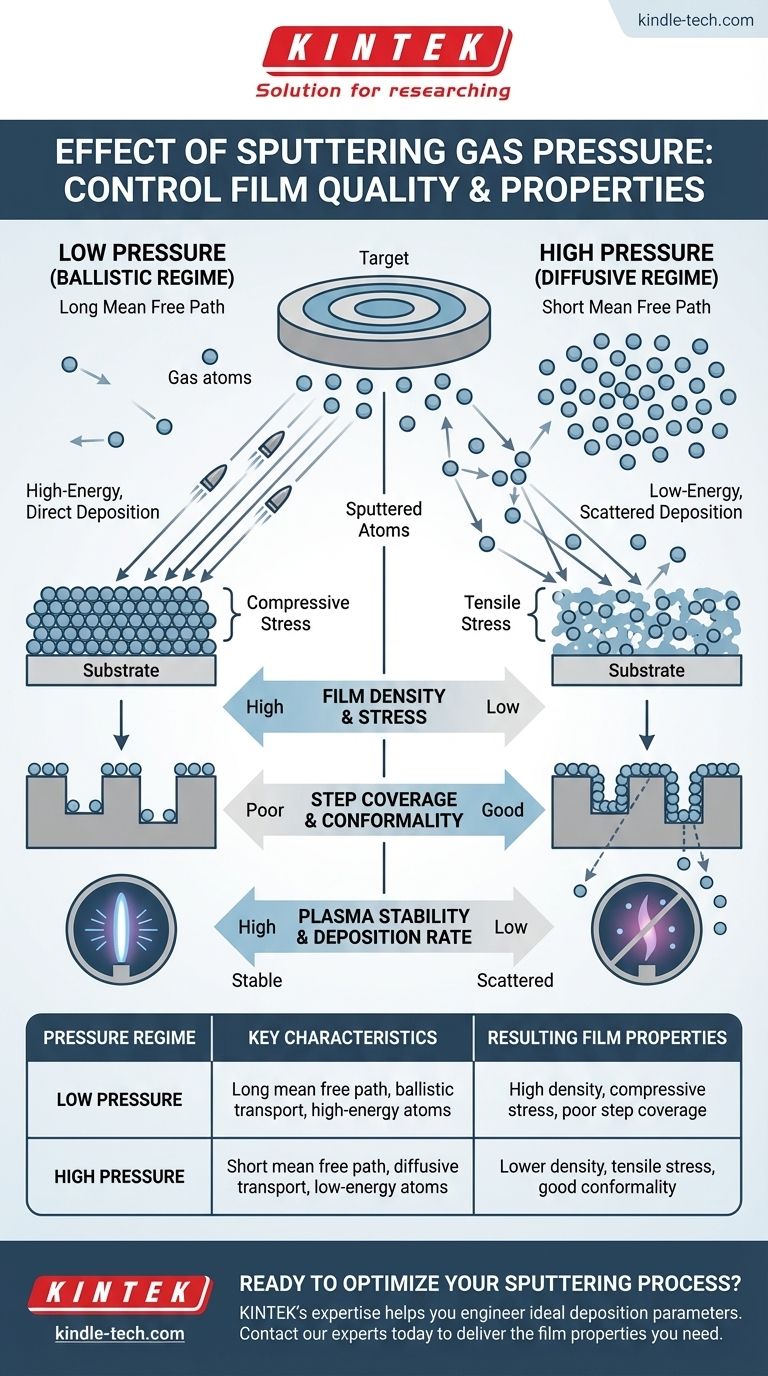

In short, sputtering gas pressure is one of the most critical parameters for controlling the quality and properties of your deposited film. It directly governs the energy and trajectory of the sputtered atoms as they travel from the target to your substrate. Lower pressures result in high-energy, direct deposition, while higher pressures lead to lower-energy, scattered deposition.

The core principle to understand is the trade-off between two distinct physical regimes. You are not just adjusting pressure; you are choosing whether your sputtered atoms travel like a direct, high-speed bullet (low pressure) or diffuse like a gentle cloud of mist (high pressure).

How Pressure Defines the Deposition Regime

To understand the effect of pressure, you must first visualize the journey of a single atom. After being ejected from the target, it must travel through a chamber filled with gas atoms (typically Argon) to reach your substrate.

The Key Concept: Mean Free Path

The mean free path is the average distance a particle can travel before it collides with another particle.

At low gas pressure, there are fewer gas atoms in the chamber. This results in a long mean free path.

At high gas pressure, the chamber is more crowded with gas atoms. This results in a short mean free path.

Low Pressure: The Ballistic Regime

When the mean free path is long, sputtered atoms are unlikely to collide with gas atoms on their way to the substrate.

They travel in a straight, line-of-sight path, retaining most of their initial high energy. This is known as ballistic transport. This high-energy impact creates a "peening" effect, resulting in a very dense and tightly packed film structure.

High Pressure: The Diffusive Regime

When the mean free path is short, sputtered atoms will undergo many collisions with gas atoms.

These collisions act as a moderator, causing the atoms to lose energy and change direction repeatedly. This is a diffusive or thermalized process. The atoms arrive at the substrate with much lower energy and from many different angles, resulting in a more porous and less dense film.

Understanding the Trade-offs

Choosing a pressure is not about finding a single "correct" value, but about balancing competing film properties to achieve your specific goal.

Film Density and Stress

This is the most direct trade-off. The high-energy, ballistic deposition at low pressure typically creates films with higher density but also higher compressive stress.

Conversely, the low-energy, diffusive deposition at high pressure leads to films with lower density and often results in tensile stress.

Step Coverage and Conformality

If you are coating a complex, non-flat surface, a higher pressure can be beneficial.

The scattering effect of the diffusive regime allows atoms to "wrap around" features, leading to better conformal coverage on an intricate topography. Ballistic, line-of-sight deposition would simply coat the top surfaces and leave the sidewalls bare.

Plasma Stability and Deposition Rate

The pressure also affects the plasma itself. If the pressure is too low, it can be difficult to ignite or sustain a stable plasma discharge.

If the pressure is too high, excessive scattering can prevent sputtered atoms from ever reaching the substrate, which can significantly decrease your effective deposition rate.

Making the Right Choice for Your Goal

Your optimal sputtering pressure is entirely dependent on the desired properties of your final film.

- If your primary focus is maximum film density: Use the lowest pressure that allows for a stable plasma to promote high-energy, ballistic deposition.

- If your primary focus is conformal coating of a complex surface: Use a higher pressure to encourage diffusive, scattered transport of the sputtered material.

- If your primary focus is controlling film stress: Carefully adjust the pressure to navigate the transition point between compressive (low P) and tensile (high P) stress for your specific material.

By understanding pressure's role, you move from simply following a recipe to intelligently engineering your film's fundamental properties.

Summary Table:

| Pressure Regime | Key Characteristics | Resulting Film Properties |

|---|---|---|

| Low Pressure | Long mean free path, ballistic transport, high-energy atoms | High density, compressive stress, poor step coverage |

| High Pressure | Short mean free path, diffusive transport, low-energy atoms | Lower density, tensile stress, good conformality |

Ready to Optimize Your Sputtering Process?

Understanding the critical role of sputtering gas pressure is the first step to achieving superior thin films. Whether your goal is maximum film density, precise stress control, or perfect conformal coating on complex surfaces, KINTEK's expertise in lab equipment and consumables can help you engineer the ideal deposition parameters.

Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and deliver the film properties you need.

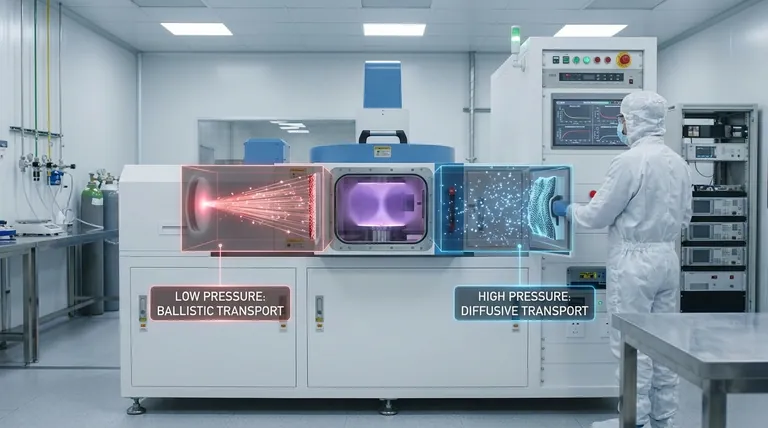

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials