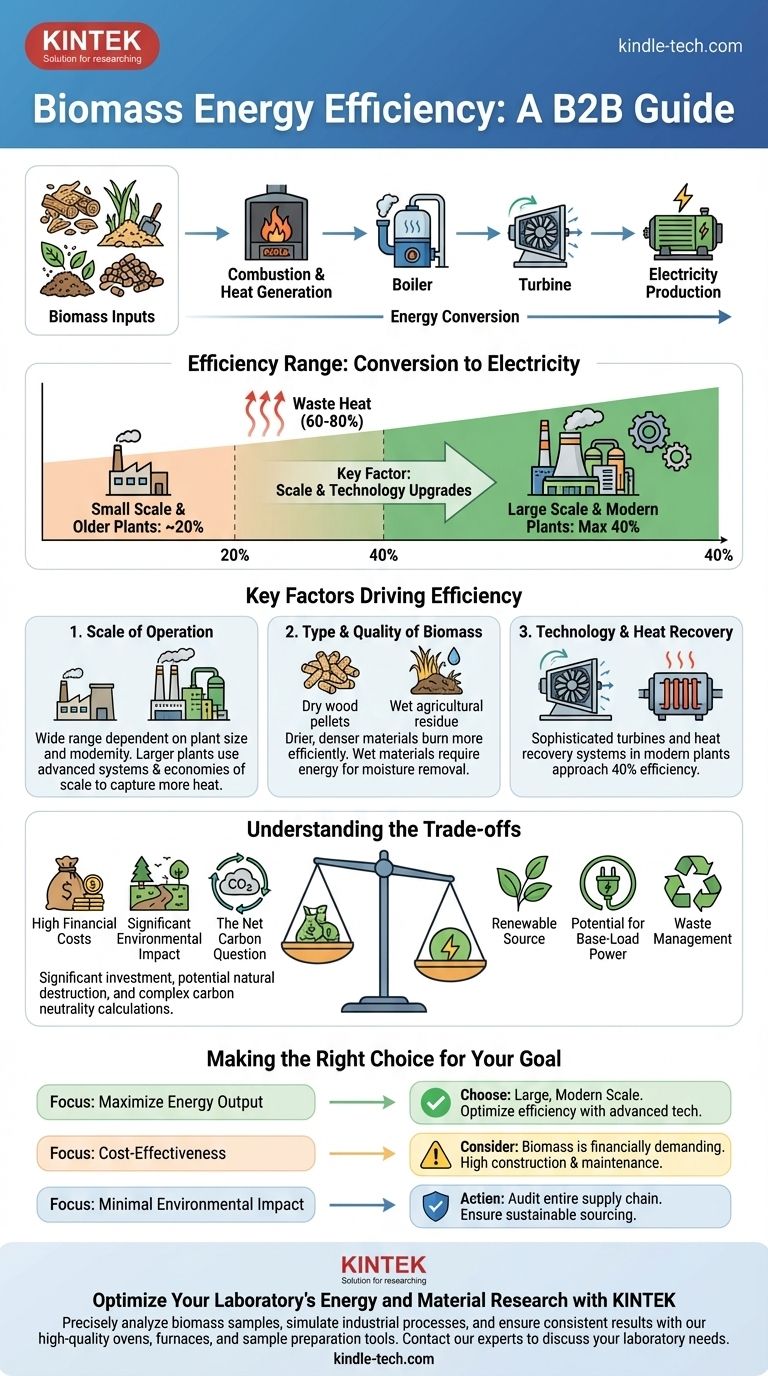

The energy efficiency of producing electricity from biomass typically ranges from 20% for smaller operations to a maximum of 40% for large-scale, modern power plants. This efficiency measures how much of the organic matter's stored chemical energy is successfully converted into usable electrical energy through combustion.

While the 20-40% efficiency range is a critical starting point, the true viability of biomass as an energy source depends less on this number and more on the scale of the operation and the significant economic and environmental trade-offs involved.

What "Efficiency" Means for Biomass

The Core Process: Conversion to Electricity

Biomass energy is generated from organic materials such as wood, agricultural waste, or other plant-based matter. The most common method involves burning this biomass to produce heat, which creates steam to turn a turbine and generate electricity.

Measuring the Conversion Rate

Energy efficiency, in this context, is the percentage of the biomass's potential energy that is successfully converted into electricity. An efficiency of 40% means that for every 100 units of energy stored in the raw biomass, only 40 units become usable electricity, with the remaining 60 units lost, primarily as waste heat.

Key Factors Driving Biomass Efficiency

The Critical Role of Scale

The wide efficiency range is almost entirely dependent on the size and modernity of the power-generating facility. Smaller enterprises often lack the advanced technology and economies of scale needed to capture and use heat effectively, resulting in efficiencies around 20%.

Large, modern power plants, however, can invest in more sophisticated turbines and heat recovery systems. This allows them to achieve efficiencies that approach 40%, making them twice as effective at converting fuel to power.

Type and Quality of Biomass

The specific type of organic matter used also plays a role. Drier, denser biomass like wood pellets will burn more efficiently than wetter materials like fresh agricultural residue, which requires more energy to eliminate moisture before combustion can occur.

Understanding the Trade-offs

High Financial Costs

Biomass energy is not a low-cost solution. The process involves significant financial investment in the construction of the plant, the ongoing production and processing of the biomass fuel, and regular facility maintenance. These high costs can be a major barrier to adoption.

Significant Environmental Impact

While considered renewable, biomass is not without environmental consequences. Sourcing the organic matter can lead to natural destruction if not managed sustainably, potentially contributing to deforestation or competing with land used for food production.

The Net Carbon Question

Burning biomass releases carbon dioxide into the atmosphere. The argument for its carbon neutrality rests on the idea that the CO2 released is offset by the carbon absorbed by the plants as they grew. However, this is a complex calculation that depends heavily on the entire lifecycle, from harvesting to transportation and processing.

Making the Right Choice for Your Goal

When evaluating biomass, your primary objective will determine its suitability.

- If your primary focus is maximizing energy output from a renewable source: Biomass is most effective at a large, modern scale where its efficiency can be optimized.

- If your primary focus is cost-effectiveness: The high construction, production, and maintenance costs make biomass a financially demanding choice compared to some other renewable technologies.

- If your primary focus is minimal environmental impact: You must carefully audit the entire supply chain to ensure the biomass is sourced sustainably without causing land degradation or deforestation.

Ultimately, evaluating biomass requires looking beyond a single efficiency number to the complete economic and ecological system it operates within.

Summary Table:

| Factor | Impact on Efficiency |

|---|---|

| Scale of Operation | Small plants: ~20%. Large, modern plants: Up to 40%. |

| Biomass Type & Quality | Dry, dense materials (e.g., wood pellets) are more efficient than wet residues. |

| Technology & Heat Recovery | Advanced systems in modern plants capture more usable energy, boosting efficiency. |

Optimize Your Laboratory's Energy and Material Research with KINTEK

Whether you are developing new biomass feedstocks, analyzing combustion processes, or testing material durability under high temperatures, having the right laboratory equipment is crucial for accurate and efficient research. KINTEK specializes in providing high-quality lab equipment and consumables tailored to the needs of research and industrial laboratories.

We can help you:

- Precisely analyze biomass samples with our reliable ovens, furnaces, and sample preparation tools.

- Simulate industrial processes to test efficiency and outcomes in a controlled lab environment.

- Ensure consistent, repeatable results with our durable and precise equipment.

Let KINTEK be your trusted partner in advancing your energy and materials research. Contact our experts today to discuss your specific laboratory needs and find the perfect solution.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the regeneration temperature of activated carbon? Optimize Your Process with the Right Method

- What are the advantages of rotary kiln furnace? Achieve Superior Uniformity & Efficiency

- What is the chemical reaction of pyrolysis? A Guide to Controlled Thermal Decomposition

- What happens after calcination? A Guide to Material Transformation and Next Steps

- What is a rotary kiln reactor? A Guide to Industrial Thermal Processing

- What is the purpose of the rotary kiln? A Guide to Continuous High-Temperature Processing

- Can you restore activated carbon? Understanding the Industrial Reactivation Process

- What is the difference between regeneration and reactivation of activated carbon? Maximize Carbon Lifespan & Performance