The full form of HFCVD is Hot Filament Chemical Vapor Deposition. It is a materials science technique used to grow high-quality thin films and crystalline materials, most notably synthetic diamond, from a gas state onto a solid surface (a substrate). The process relies on a heated wire, or filament, to provide the energy needed to break down precursor gases and initiate the deposition process.

HFCVD is a widely used method for creating high-purity thin films because it offers a simpler and more cost-effective alternative to other energy-intensive techniques. Its core principle is using a super-heated wire to trigger the chemical reactions necessary for material growth on a nearby surface.

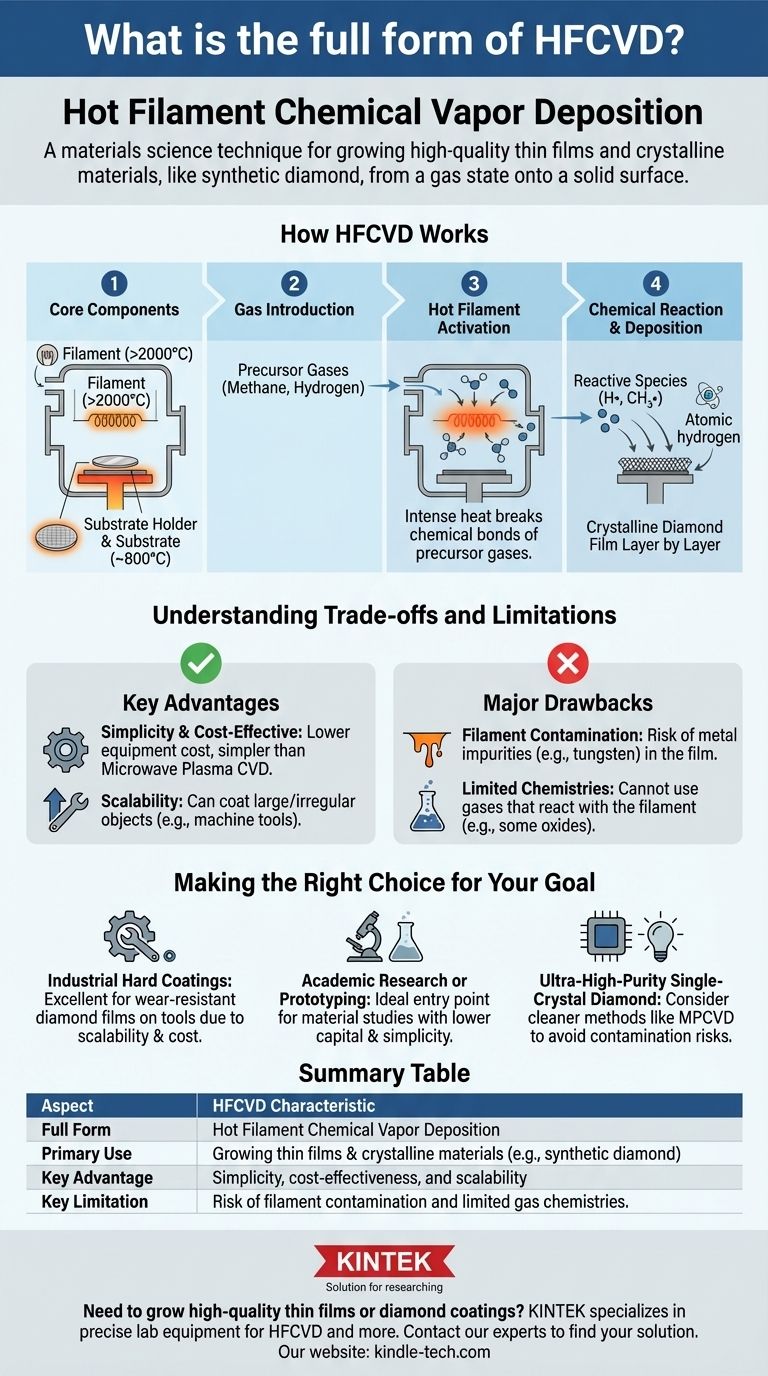

How HFCVD Works: A Step-by-Step Breakdown

To understand HFCVD, it's best to visualize it as a precise, controlled construction process happening at a microscopic level inside a vacuum chamber.

The Core Components

The setup consists of a vacuum chamber containing two key elements: a filament (usually made of tungsten or tantalum) and a substrate holder, which holds the material to be coated. Both the filament and the substrate can be heated independently.

The Gas Introduction

A carefully controlled mixture of precursor gases is introduced into the chamber at low pressure. For growing diamond, this is typically a mixture of a carbon source gas (like methane, CH₄) and a large excess of hydrogen (H₂).

The "Hot Filament" Activation

The filament is electrically heated to extremely high temperatures, often exceeding 2000°C (3632°F). This intense heat provides the thermal energy to break the chemical bonds of the precursor gas molecules that pass near it.

Chemical Reaction and Deposition

The hot filament cracks the stable methane and hydrogen molecules into highly reactive atomic hydrogen (H•) and carbon-containing radicals (like CH₃•). These reactive species then travel to the heated substrate (typically ~800°C), where they settle and form the crystalline diamond film, layer by layer. The atomic hydrogen plays a crucial secondary role by selectively etching away any non-diamond carbon (like graphite) that forms, ensuring a high-purity diamond film.

Understanding the Trade-offs and Limitations

No single technique is perfect for every application. HFCVD's main strength is its simplicity, but this comes with specific limitations that are critical to understand.

Key Advantage: Simplicity and Cost

The primary advantage of HFCVD is its relative simplicity and lower equipment cost compared to more complex methods like Microwave Plasma CVD (MPCVD). This makes it highly accessible for both research and industrial applications.

Key Advantage: Scalability

The HFCVD process can be scaled up to coat large or irregularly shaped objects by using longer filaments or arranging multiple filaments. This is a significant advantage for industrial coating applications, such as on machine tools.

Major Drawback: Filament Contamination

The biggest weakness of HFCVD is the potential for contamination from the filament itself. Over time, the hot filament can degrade and evaporate, introducing metal (e.g., tungsten) atoms into the growing film. This can be detrimental for applications requiring extreme purity, such as in high-performance electronics.

Major Drawback: Limited Chemistries

The filament can react with certain precursor gases, particularly those containing oxygen. This reactivity limits the types of materials that can be effectively grown with HFCVD, making it unsuitable for depositing some oxide ceramics.

Making the Right Choice for Your Goal

Selecting a deposition technique depends entirely on the requirements of the final product. HFCVD is a powerful tool when its strengths are aligned with the project's goals.

- If your primary focus is industrial hard coatings: HFCVD is an excellent choice for applying wear-resistant diamond films onto cutting tools or mechanical parts due to its scalability and cost-effectiveness.

- If your primary focus is academic research or prototyping: The lower capital investment and operational simplicity make HFCVD an ideal entry point for studying diamond growth and other advanced materials.

- If your primary focus is ultra-high-purity single-crystal diamond for electronics or optics: You should carefully evaluate the risk of filament contamination and consider alternative methods like MPCVD, which offers a cleaner energy source.

Ultimately, understanding the principles and limitations of Hot Filament Chemical Vapor Deposition empowers you to select the most efficient and effective method for your specific material synthesis goals.

Summary Table:

| Aspect | HFCVD Characteristic |

|---|---|

| Full Form | Hot Filament Chemical Vapor Deposition |

| Primary Use | Growing thin films & crystalline materials (e.g., synthetic diamond) |

| Key Advantage | Simplicity, cost-effectiveness, and scalability for large surfaces |

| Key Limitation | Risk of filament contamination and limited usable gas chemistries |

Need to grow high-quality thin films or diamond coatings? KINTEK specializes in providing the precise lab equipment and consumables you need for techniques like HFCVD. Whether you're scaling up an industrial coating process or conducting advanced materials research, our expertise can help you achieve superior results. Contact our experts today to discuss your specific application and find the perfect solution for your laboratory.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings