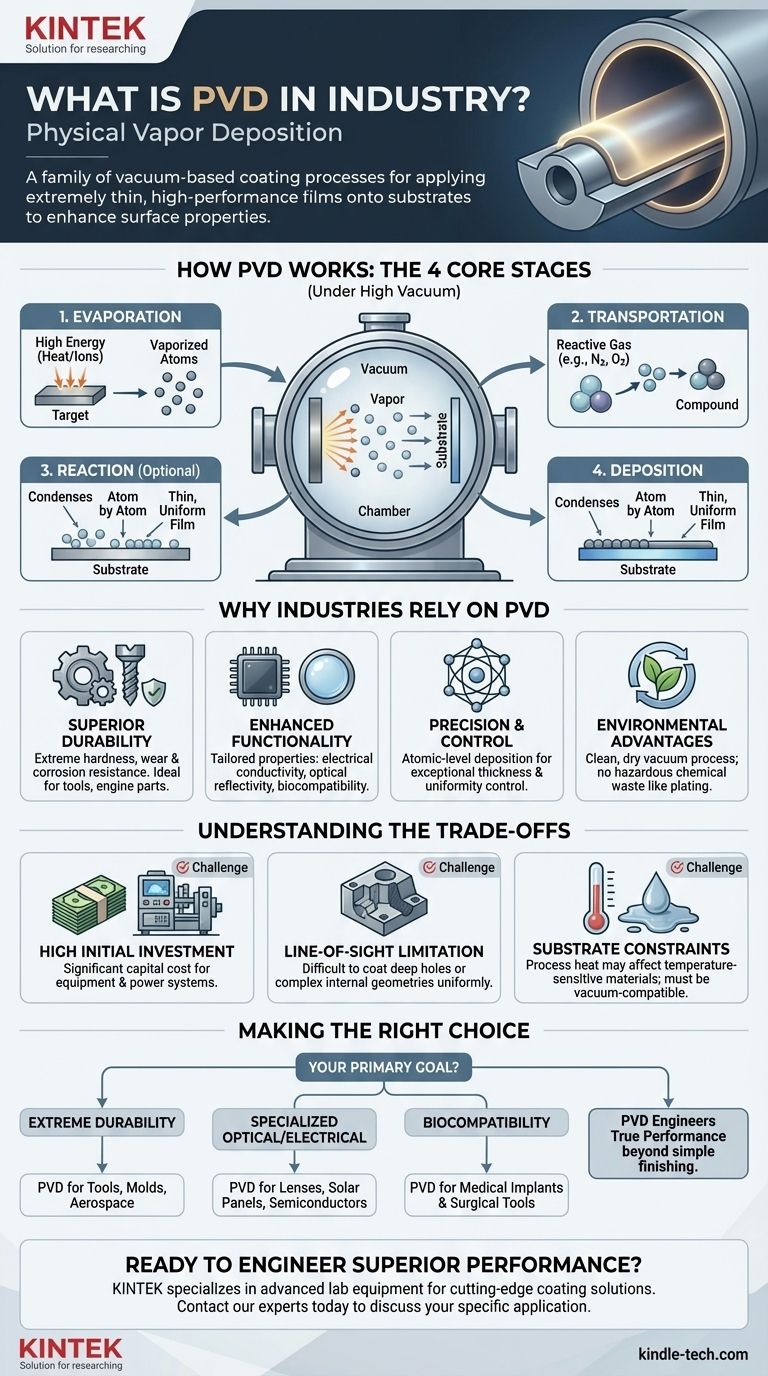

In an industrial context, PVD stands for Physical Vapor Deposition. It is a family of vacuum-based coating processes used to apply extremely thin, high-performance films onto a substrate. These coatings fundamentally enhance the surface properties of a component, improving its durability, function, or appearance without altering its underlying material.

Physical Vapor Deposition is not a single technique but a category of processes that transform a solid material into a vapor, which then condenses onto a target object as a thin, durable film. This method is used to engineer specific surface properties, from extreme hardness to unique optical or electrical characteristics.

How Does Physical Vapor Deposition Work?

PVD is a highly controlled, atomic-level transfer of material. While different PVD methods exist, they all share a common procedural framework that takes place within a vacuum chamber.

The Critical Role of the Vacuum

The entire PVD process occurs under a high vacuum. This is essential to remove air and other gas particles that could react with or contaminate the coating material, ensuring the purity and integrity of the final film.

The Four Core Stages

The process can be broken down into four distinct steps.

-

Evaporation: The process begins with a solid source material, often called the "target." High energy is applied to this target—either through intense heat or bombardment with ions—causing it to transition directly into a vapor state.

-

Transportation: The vaporized atoms or molecules travel from the source material across the vacuum chamber towards the substrates, which are the parts being coated.

-

Reaction: For certain applications, a reactive gas (like nitrogen, oxygen, or acetylene) is introduced into the chamber. This gas reacts with the metal vapor to form a specific compound coating (e.g., titanium vapor reacting with nitrogen to form Titanium Nitride).

-

Deposition: As the vaporized material reaches the cooler surface of the substrates, it condenses, forming a thin, dense, and highly adherent film. This film builds up atom by atom, creating an exceptionally uniform layer.

Why Industries Rely on PVD

PVD is not simply an alternative to paint or electroplating; it is a high-performance surface engineering tool used to achieve results that other methods cannot.

Superior Durability and Wear Resistance

PVD coatings are often extremely hard and have a low coefficient of friction. This makes them ideal for cutting tools, engine components, and firearms, where resistance to wear, abrasion, and corrosion is critical.

Enhanced Functional Properties

The process allows for the deposition of a vast array of materials, including metals, alloys, and ceramics. This versatility is used to create coatings with specific functions, such as electrical conductivity for semiconductors, biocompatibility for medical implants, or reflective properties for optical lenses.

Precision and Control

Because the film is built one atom at a time, PVD allows for exceptional control over thickness, uniformity, and composition. This precision is essential for high-tech applications like microchips and solar panels.

Environmental Advantages

Compared to traditional wet chemical processes like chrome plating, PVD is an environmentally clean technology. It is a dry, vacuum-based process that does not produce the hazardous chemical waste associated with electroplating.

Understanding the Trade-offs

While powerful, PVD is not the solution for every coating application. Its advantages come with specific limitations that are important to understand.

High Initial Investment

PVD equipment, including vacuum chambers, high-energy power supplies, and control systems, represents a significant capital investment. This cost often makes it better suited for high-value or high-performance components.

Line-of-Sight Limitation

In most PVD processes, the coating material travels in a straight line from the source to the substrate. This makes it challenging to achieve a uniform coating on parts with complex internal geometries or deep, narrow holes.

Substrate Temperature and Material

The PVD process can generate significant heat, which may not be suitable for temperature-sensitive substrates like certain plastics. The substrate material must also be compatible with the high-vacuum environment.

Making the Right Choice for Your Goal

Selecting a coating process depends entirely on your project's performance requirements and economic constraints.

- If your primary focus is extreme durability and corrosion resistance: PVD is an excellent choice for hard-wearing surfaces on tools, industrial molds, and aerospace components.

- If your primary focus is specialized optical or electrical properties: PVD is the industry standard for coating lenses, solar panels, and semiconductor wafers with precise, functional films.

- If your primary focus is biocompatibility for medical devices: PVD is critical for applying inert, safe coatings to medical implants and surgical tools.

- If your primary focus is low-cost, high-volume finishing: You must weigh the superior performance of PVD against the higher cost and slower cycle times compared to alternatives like powder coating or electroplating.

Ultimately, understanding PVD allows you to move beyond simple surface finishing and begin engineering true performance into your products.

Summary Table:

| Key Aspect | Details |

|---|---|

| Full Form | Physical Vapor Deposition |

| Primary Function | Applies thin, high-performance films to a substrate |

| Key Advantages | Superior wear resistance, precision control, environmental benefits |

| Common Applications | Cutting tools, medical implants, semiconductors, optical lenses |

| Main Limitation | Line-of-sight process, high initial investment |

Ready to Engineer Superior Performance into Your Products?

PVD coating technology can provide the durable, high-performance surface your components need to excel. KINTEK specializes in advanced lab equipment and consumables, serving the precise needs of laboratories and industries that rely on cutting-edge coating solutions.

Contact our experts today to discuss how our solutions can help you achieve unparalleled durability, functionality, and precision for your specific application.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition