At its core, a rotary tablet press is a high-speed mechanical device designed for the mass production of uniform tablets from granular material or powder. It functions by using a rotating turret that holds a series of dies and punches, allowing for the continuous compression of material into tablets as the turret spins.

The central challenge in tablet manufacturing is balancing production speed with consistent quality. A rotary tablet press solves this by moving beyond a single-punch system, instead utilizing multiple "stations" that compress tablets simultaneously and continuously, achieving massive output without sacrificing precise control over tablet weight, hardness, and thickness.

How a Rotary Press Achieves High-Volume Production

The defining feature of a rotary tablet press is its continuously rotating turret, which contains the dies that shape the tablets. This design is what separates it from slower, single-station presses and enables industrial-scale output.

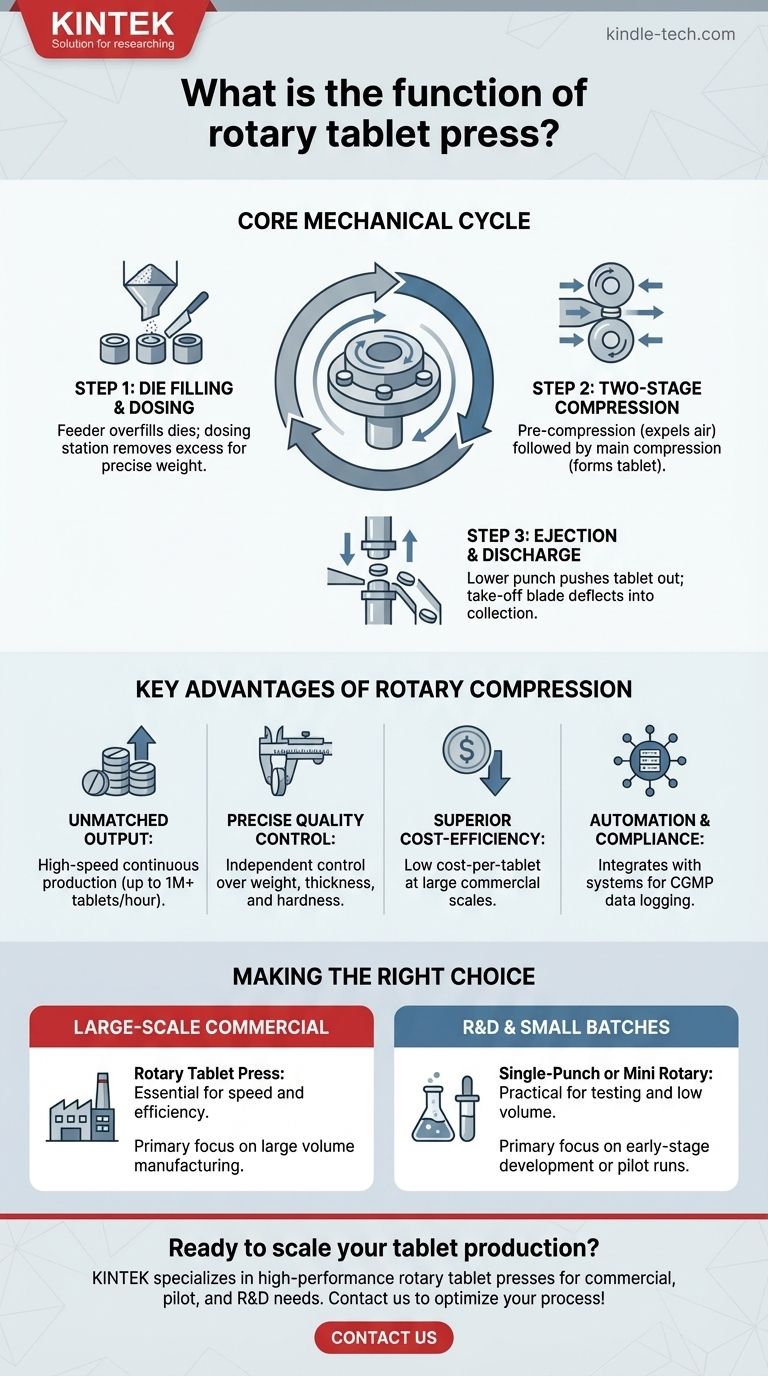

The Core Mechanical Cycle

The machine's operation is a continuous, circular process. As the turret rotates, each individual die and its associated upper and lower punches pass through a series of fixed cams and rollers that control the entire tableting sequence.

Step 1: Die Filling and Dosing

A feeder system moves powder from a large hopper and overfills the die cavities as they pass underneath. Immediately after, a dosing station scrapes away excess powder, ensuring each die contains a precise, consistent volume of material. This step is critical for controlling the final tablet weight.

Step 2: Two-Stage Compression

The filled dies then travel between two sets of rollers. First, pre-compression rollers apply a light force to expel any trapped air from the powder. Immediately following this, the main compression rollers apply significant force, pressing the powder into a hard, solid tablet.

Step 3: Ejection and Discharge

After main compression, the lower punch is guided up by an ejection cam, pushing the finished tablet out of the die cavity and flush with the turret surface. A take-off blade then deflects the tablet off the turret and into a discharge chute, where it is collected.

The Key Advantages of Rotary Compression

The mechanics of a rotary press directly translate into several critical advantages for commercial manufacturing, making it the industry standard for high-volume production.

Unmatched Production Output

By having many punch and die stations operating simultaneously, a rotary press can produce hundreds of thousands, and in some cases over a million, tablets per hour. This is an order of magnitude greater than single punch presses.

Precise Quality Control

Modern rotary presses allow for independent control over key tablet attributes. Operators can precisely adjust the fill depth to control tablet weight and modify the compression force to control tablet thickness and hardness.

Superior Cost-Efficiency at Scale

While the initial investment is significant, the high output rate dramatically lowers the cost-per-tablet in large production runs. This makes it far more economical for commercial manufacturing than any other method.

Automation and Compliance

These machines are designed to integrate with facility network systems for remote monitoring and data logging. This capability is essential for adhering to stringent regulations like Current Good Manufacturing Practices (CGMP) by providing a detailed record of the production run.

Understanding the Trade-offs

Despite its advantages, a rotary press is not the right tool for every application. Understanding its limitations is key to making a sound investment.

High Initial Investment and Complexity

Rotary tablet presses are complex, heavy-duty machines that represent a significant capital expense. They also require skilled operators for setup, operation, cleaning, and maintenance, adding to the operational cost.

Inefficiency for Small Batches

The time and material required for setup and cleaning make rotary presses highly inefficient for very small batches, such as those used in early-stage research and development. The amount of powder wasted during priming can be substantial.

Formulation and Tooling Requirements

The high-speed nature of the machine demands that the powder formulation has excellent flow properties to ensure the dies fill uniformly. Furthermore, the tooling (punches and dies) must be engineered to withstand immense stress and are a significant recurring cost.

Making the Right Choice for Your Goal

Selecting the correct tableting technology depends entirely on your production volume and specific application.

- If your primary focus is large-scale commercial manufacturing: A full-size rotary tablet press is the essential standard for achieving the required speed and cost-efficiency.

- If your primary focus is pilot batches or regulated small-scale production: A "mini" rotary tablet press provides the same quality control benefits but at a lower output (e.g., 5,000-20,000 tablets/hour) and smaller footprint.

- If your primary focus is early-stage R&D or formulation development: A simpler, single-punch press is often more practical, as it requires very little material and is easier to operate for testing individual tablet characteristics.

By understanding these distinctions, you can align the right machine with your operational scale and business objectives.

Summary Table:

| Feature | Benefit |

|---|---|

| Rotating Turret with Multiple Stations | Simultaneous compression for high output (up to 1M+ tablets/hour) |

| Two-Stage Compression (Pre & Main) | Ensures uniform tablet density and eliminates air pockets |

| Precise Fill Depth & Compression Force Control | Consistent tablet weight, hardness, and thickness |

| Automated Data Logging | Supports CGMP compliance and quality assurance |

| High Initial Investment | Cost-effective for large-scale commercial production |

Ready to scale your tablet production with precision and efficiency? KINTEK specializes in lab equipment and consumables, serving laboratory needs with high-performance rotary tablet presses. Whether you're in commercial manufacturing, pilot-scale production, or R&D, our solutions are designed to deliver consistent quality and maximize your output. Contact us today to find the perfect tableting press for your specific requirements and let our experts help you optimize your process!

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What is the working principle of pelletizing machine? Transform Powders into Dense, Uniform Pellets

- What is the advantage of a single punch tablet machine? Ideal for Low-Waste R&D and Formulation Testing

- What are the different parts of a single punch tablet machine? The Core Components Explained

- How does a rotary tablet press work? A Guide to High-Speed Tablet Manufacturing

- What is the use of single punch tablet press? For Precise R&D and Small-Batch Tablet Production

- What does a tablet punching machine consist of? Core Components for Efficient Tablet Production

- What type of die is used in pellet mills? Choose Between Flat Die and Ring Die for Your Production Scale

- How does a mechanical pelletizer extend the life of calcium-based adsorbents? Maximize Your Adsorbent Durability