In essence, a laboratory furnace is a high-temperature oven used to perform a wide range of thermal processing tasks. Its fundamental function is to subject materials to a precisely controlled temperature environment to induce physical or chemical changes, such as preparing samples for analysis, synthesizing new materials, or testing thermal properties.

The core purpose of a laboratory furnace is not just to heat things up, but to use controlled, high temperatures as a tool to transform a material—purifying it, changing its structure, or determining its composition.

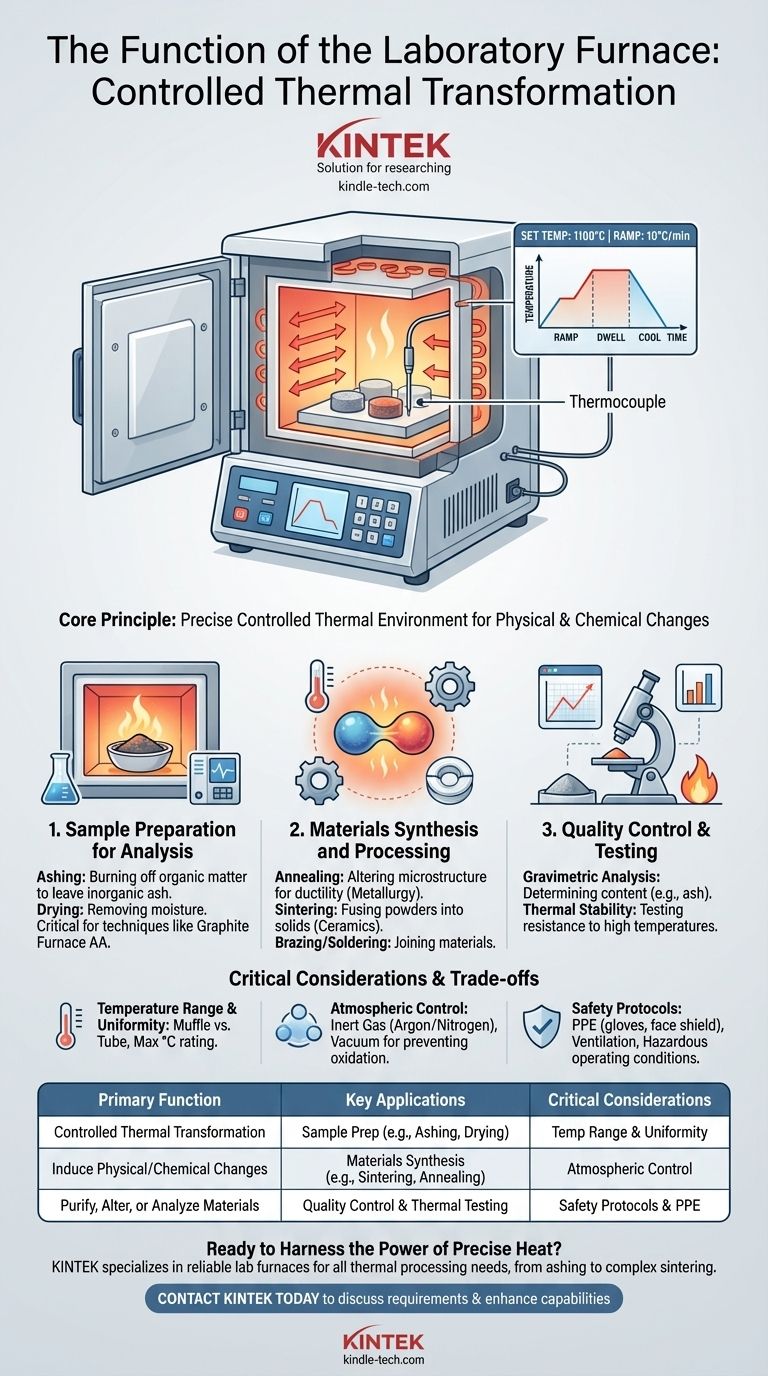

The Core Principle: Controlled Thermal Transformation

A laboratory furnace provides a highly uniform and accurate thermal environment, which is critical for reproducible scientific and industrial processes. Unlike a simple oven, it is engineered for extreme temperatures and precise control.

What Defines a Lab Furnace?

A true laboratory furnace offers precise temperature control, often with programmable ramps (heating up at a specific rate) and dwells (holding a specific temperature).

This control is managed by a thermocouple that measures the internal temperature and a digital controller that adjusts power to the heating elements. This system ensures the process is both accurate and repeatable.

Key Applications in Science and Industry

The function of a furnace is best understood through its applications. These processes span from basic sample preparation to advanced materials science.

Sample Preparation for Analysis

This is one of the most common uses. Before a material can be analyzed, it often needs to be purified or have interfering substances removed.

The reference you provided points to a perfect example: ashing. This process involves heating a sample to burn off all organic matter, leaving behind only the inorganic components (the "ash") for analysis. As noted, this is critical in techniques like graphite furnace atomic absorption (AA) to remove "matrix constituents" that would interfere with the measurement.

Materials Synthesis and Processing

Furnaces are indispensable tools for creating and modifying materials.

Annealing is a heat treatment process that alters a material's microstructure to make it more ductile and less brittle. This is common in metallurgy.

Sintering is used to create solid objects from powders. By heating the powder below its melting point, the particles fuse, forming a strong, solid piece. This is a cornerstone of ceramics manufacturing.

Brazing and soldering use furnaces to join materials, especially in complex assemblies where torch heating is impractical.

Understanding the Trade-offs and Considerations

While powerful, using a furnace requires understanding its capabilities and limitations to ensure the desired outcome.

Temperature Range and Uniformity

Not all furnaces are created equal. A muffle furnace is a general-purpose box furnace, while a tube furnace provides a more controlled atmosphere within a cylindrical chamber.

The maximum temperature rating is a critical specification. A furnace designed for 500°C cannot be used for a 1200°C ceramic sintering process.

Atmospheric Control

Many materials react with oxygen at high temperatures (oxidation). For these processes, a furnace must have the ability to operate under a vacuum or be purged with an inert gas like argon or nitrogen. This prevents unwanted chemical reactions.

Safety Protocols

Operating a high-temperature furnace is inherently hazardous. Proper personal protective equipment (PPE), including heat-resistant gloves and face shields, is mandatory. Adequate ventilation is also critical to remove any fumes generated during the process.

Making the Right Choice for Your Goal

The specific function of the furnace is dictated entirely by your objective.

- If your primary focus is quantitative chemical analysis: You will likely use the furnace for sample preparation, employing techniques like ashing or drying to isolate the analyte of interest and remove interferences.

- If your primary focus is materials science: You are using the furnace as a production tool for annealing, sintering, or synthesizing materials to achieve specific physical and chemical properties.

- If your primary focus is quality control: You might use the furnace to perform gravimetric analysis (like determining ash content) or to test a material's thermal stability and resistance to high temperatures.

Ultimately, a laboratory furnace is an essential instrument for harnessing high temperatures to precisely control the state of matter.

Summary Table:

| Primary Function | Key Applications | Critical Considerations |

|---|---|---|

| Controlled Thermal Transformation | Sample Preparation (e.g., Ashing, Drying) | Temperature Range & Uniformity |

| Induce Physical/Chemical Changes | Materials Synthesis (e.g., Sintering, Annealing) | Atmospheric Control (Inert Gas, Vacuum) |

| Purify, Alter, or Analyze Materials | Quality Control & Thermal Testing | Safety Protocols & PPE |

Ready to Harness the Power of Precise Heat?

Whether your goal is accurate sample preparation for chemical analysis or advanced materials synthesis and processing, choosing the right laboratory furnace is critical to your success.

KINTEK specializes in providing reliable lab furnaces and equipment tailored to your specific thermal processing needs—from basic ashing to complex high-temperature sintering under controlled atmospheres. We serve researchers, quality control labs, and materials scientists who demand precision, reproducibility, and safety.

Let us help you achieve your thermal transformation goals. Our experts can guide you to the ideal solution for your application.

Contact KINTEK today to discuss your laboratory furnace requirements and enhance your capabilities!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between a furnace and an oven in a laboratory? Choose the Right Tool for Your Lab's Heat Needs

- What is the thermal debinding process? A Guide to Safe Binder Removal for MIM & Ceramics

- What is the use of high temperature muffle furnace? Achieve Pure, Contamination-Free Thermal Processing

- What is the purpose of a laboratory furnace? Achieve Precise High-Temperature Processing

- What is the annealing temperature of quartz? Achieve Optimal Thermal Stability for Your Components