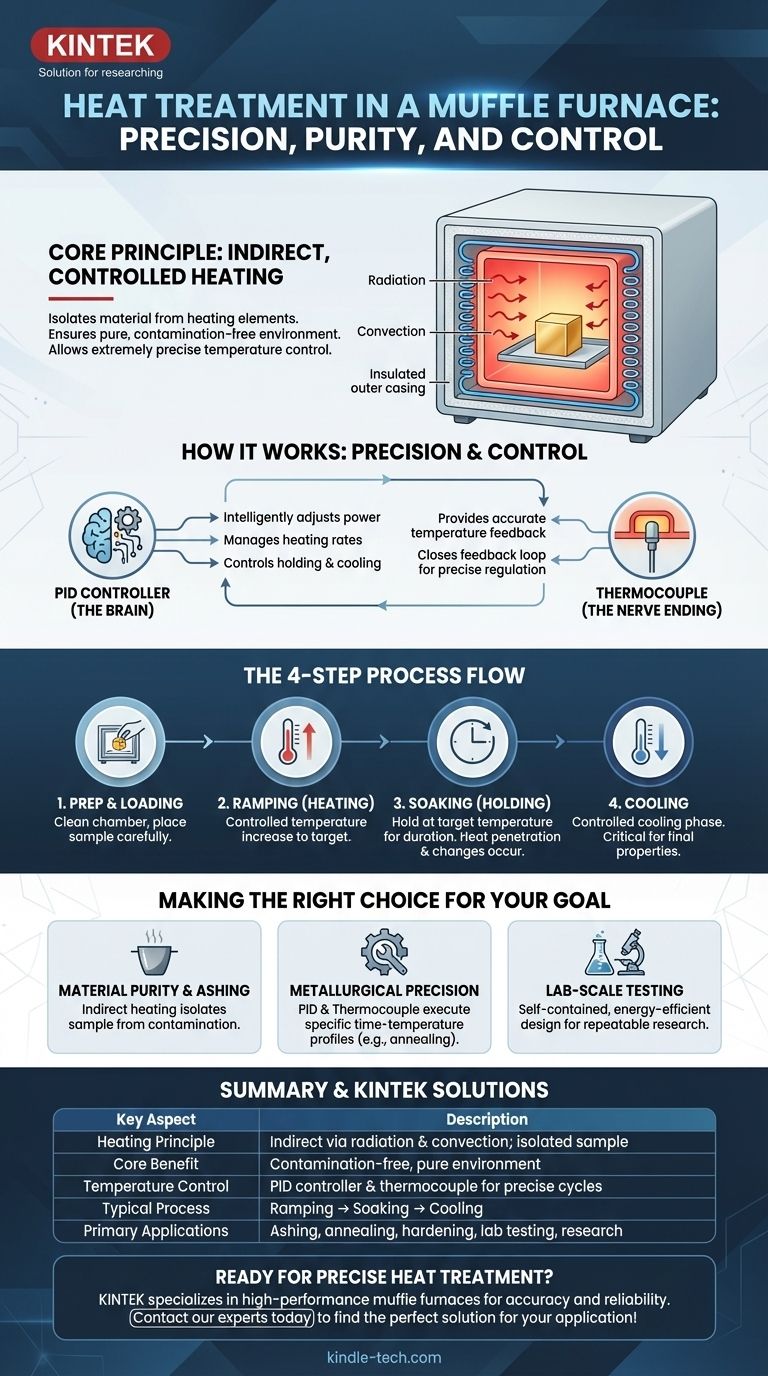

In essence, heat treatment in a muffle furnace is a process that uses a high-temperature, electrically heated chamber to alter the physical or chemical properties of a material. Its defining characteristic is the "muffle"—an insulated inner chamber that isolates the material being treated from the heating elements. This separation ensures a pure heating environment, free from contaminants, and allows for extremely precise temperature control.

The core principle of a muffle furnace is indirect, controlled heating. The goal is not just to make something hot, but to do so in a clean, uniform environment where the material is protected from direct contact with the energy source, ensuring predictable and repeatable results.

How a Muffle Furnace Achieves Precise Heating

To understand the treatment process, you must first understand the furnace's design. Its effectiveness comes from a combination of indirect heat application and precise electronic control.

The Principle of Indirect Heating

The term "muffle" originally meant to separate the object being heated from the flames and combustion byproducts of a fuel-fired furnace. This principle of separation is the key.

In modern electric furnaces, there is no combustion, but the principle remains. The material is placed inside the chamber, and the heating elements are located outside this inner chamber, embedded in the insulating walls.

Heat Transfer via Radiation and Convection

The electric heating elements, often made of a resistive material like Nichrome, generate intense heat through electrical resistance (Joule heating).

This heat is not applied directly to the sample. Instead, the elements heat the internal walls of the refractory chamber. These hot walls then transfer thermal energy to the material inside uniformly through radiation and convection.

The Role of the Insulated Chamber

The chamber itself is built from highly insulated, refractory materials. This insulation serves two critical functions:

- It prevents heat from escaping, making the furnace highly energy-efficient.

- It helps maintain a stable and uniform temperature throughout the chamber's interior.

The Components of Control

A muffle furnace is more than a simple hot box; it is a precision instrument. This precision is managed by its electronic control system.

The PID Controller

The Proportional-Integral-Derivative (PID) controller is the brain of the furnace. It receives temperature data and intelligently adjusts the power sent to the heating elements to precisely match a pre-set temperature profile. It can manage heating rates, holding times, and cooling cycles.

The Thermocouple

The thermocouple acts as the furnace's nerve ending. It is a temperature sensor placed inside the chamber that continuously provides an accurate temperature reading back to the PID controller, closing the feedback loop and enabling precise regulation.

The Heat Treatment Process Step-by-Step

A typical heat treatment cycle involves several distinct, controlled phases that are critical for achieving the desired material properties.

1. Preparation and Loading

Before the cycle begins, the furnace chamber is cleaned to prevent contamination. The material or sample to be treated is then carefully placed inside.

2. Ramping (Heating)

The user programs the desired temperature into the controller. The furnace then begins to "ramp" up, increasing its internal temperature at a controlled rate until it reaches the target.

3. Soaking (Holding)

Once the target temperature is reached, the controller holds it there for a specified duration. This "soaking" period allows the heat to fully penetrate the material and for the desired metallurgical or chemical changes to occur.

4. Cooling

After the soaking phase is complete, the power to the heating elements is shut off. The cooling phase is often just as critical as the heating phase, as the rate of cooling can significantly impact the material's final microstructure and properties.

Making the Right Choice for Your Goal

Understanding the core principles allows you to use the muffle furnace effectively for specific applications.

- If your primary focus is material purity and ashing: The furnace's indirect heating is its greatest strength, as it isolates your sample from any potential contamination from the heating elements.

- If your primary focus is precise metallurgical processes like annealing or hardening: The combination of a PID controller and thermocouple gives you the ability to execute specific time-temperature profiles with high accuracy.

- If your primary focus is repeatable lab-scale testing: The self-contained, energy-efficient design makes it an ideal and reliable tool for a wide range of research applications.

By controlling the flow of clean, indirect heat, you can leverage the muffle furnace not just as a heater, but as a precision instrument for material transformation.

Summary Table:

| Key Aspect | Description |

|---|---|

| Heating Principle | Indirect heating via radiation & convection; sample isolated from elements |

| Core Benefit | Contamination-free, pure environment for sensitive materials |

| Temperature Control | PID controller & thermocouple for precise, repeatable heating cycles |

| Typical Process | Ramping → Soaking (holding) → Cooling phases |

| Primary Applications | Ashing, annealing, hardening, lab testing, and material research |

Ready to achieve precise, contamination-free heat treatment in your lab? KINTEK specializes in high-performance muffle furnaces and lab equipment designed for accuracy and reliability. Whether you're working on material testing, ashing, or metallurgical processes, our solutions ensure uniform heating and repeatable results. Contact our experts today to find the perfect furnace for your specific application and enhance your laboratory's capabilities!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Is sintering the same as welding? Key Differences in Material Bonding and Fusion Explained

- What is the objective of a muffle furnace? Achieve Pure, High-Temperature Processing

- What are the working principles of furnace? A Guide to Combustion, Resistance, and Induction Heating

- What is SV and PV in a muffle furnace? Master Temperature Control for Precision Results

- At what temperature does quartz soften? Understand the practical limits for lab equipment