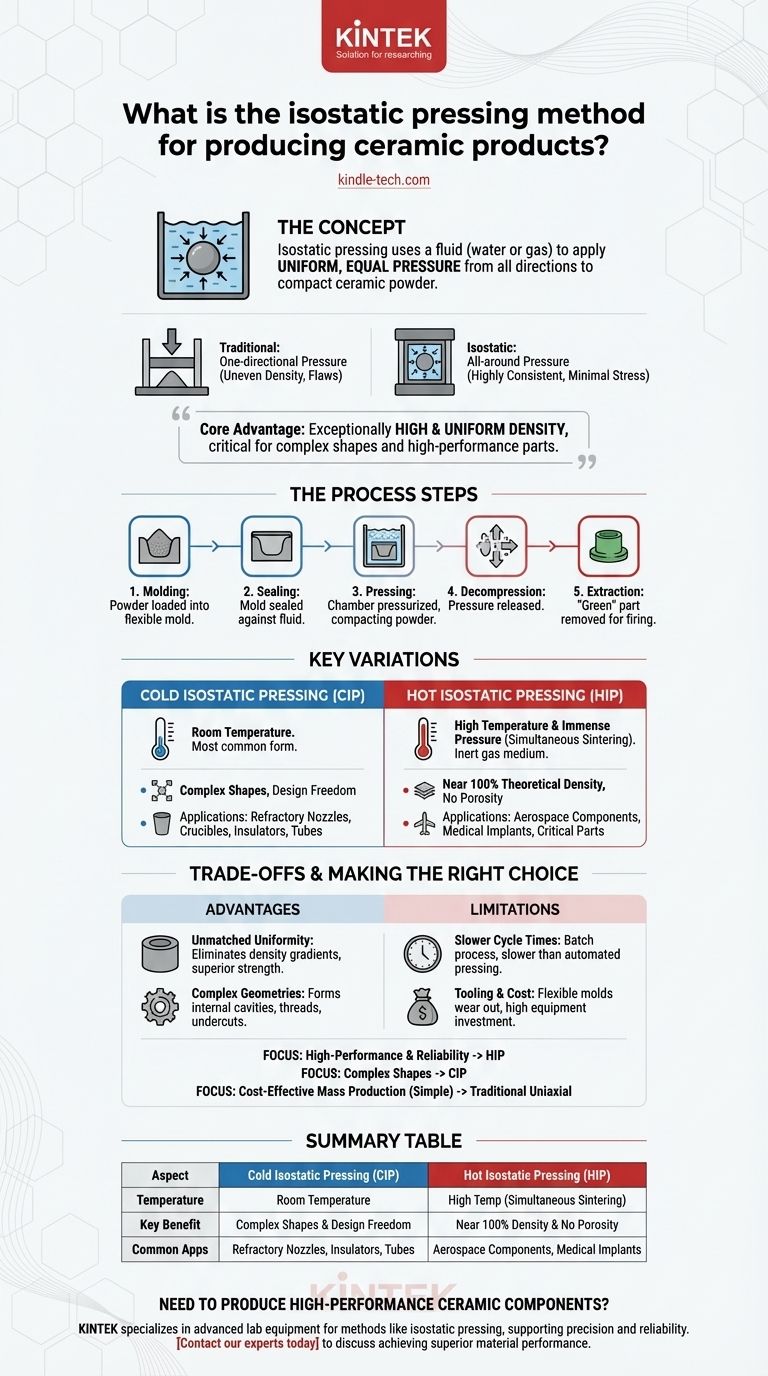

To put it simply, isostatic pressing is a powder-forming method that uses a fluid—like water or gas—to apply uniform, equal pressure from all directions to compact ceramic powder into a solid, uniform object. This all-around pressure creates a highly consistent "green" part (an unfired state) with minimal internal stresses or weak points, which is then fired to achieve its final hardness and strength.

The core advantage of isostatic pressing over traditional methods is its ability to produce ceramic components with exceptionally high and uniform density. This uniformity is critical for creating complex shapes and high-performance parts that are free from the structural flaws often introduced by one-directional pressing.

The Mechanics of Isostatic Pressing

To understand why this method is so effective, we must look at how it differs fundamentally from conventional techniques. Instead of a piston pressing powder in a rigid die, isostatic pressing immerses the powder in a pressure-transmitting medium.

The Core Principle: Uniform Pressure

The process is based on Pascal's Law, which states that pressure exerted on a confined fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

This means that a ceramic powder sealed in a flexible mold and submerged in a fluid will be compacted with perfectly even pressure from every possible angle simultaneously.

The Process Steps

The method involves a few key stages:

- Molding: The fine ceramic powder is loaded into a flexible, watertight mold, typically made of rubber or urethane.

- Sealing: The mold is sealed to prevent the fluid from contaminating the powder.

- Pressing: The sealed mold is placed into a high-pressure chamber filled with a fluid. The chamber is then pressurized, compacting the powder into a solid mass.

- Decompression: The pressure is released, and the mold is removed from the chamber.

- Extraction: The compacted "green" ceramic part is carefully removed from the mold, ready for subsequent drying and firing (sintering).

The Result: A "Green" Compact

The output of this process is a "green" part. It has enough strength to be handled and machined, but it has not yet undergone the final firing process that fuses the ceramic particles together, giving it its final hardness, density, and durability.

Key Variations of the Method

Isostatic pressing is broadly divided into two categories based on temperature, each suited for different applications and outcomes.

Cold Isostatic Pressing (CIP)

Cold Isostatic Pressing (CIP) is performed at or near room temperature. It is the most common form of the technique.

CIP is excellent for producing complex shapes that would be impossible with other methods. It's often used to create preforms for further machining or for parts like refractory nozzles, crucibles, ceramic insulators, and tubes for special chemical applications.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) combines immense pressure with very high temperatures simultaneously in a single step. The pressure medium is typically an inert gas like argon.

This process sinters the part at the same time it is being pressed, resulting in a final product with almost 100% theoretical density and virtually no porosity. HIP is reserved for the most demanding, high-performance applications where material failure is not an option.

Understanding the Trade-offs

While powerful, isostatic pressing is not the solution for every ceramic application. Its benefits come with specific considerations.

Advantage: Unmatched Uniformity

The uniform pressure eliminates density gradients, voids, and potential cracking points common in parts made with uniaxial (one-direction) pressing. This leads to superior mechanical strength and reliability.

Advantage: Complex Geometries

Because the pressure is fluid-based, it can form parts with complex internal cavities, threads, and undercuts. The reference examples, like spark plug insulators and oxygen sensors, highlight this capability.

Limitation: Slower Cycle Times

Isostatic pressing is a batch process. The need to load, seal, pressurize, and decompress the chamber makes it significantly slower than automated, high-speed die pressing.

Limitation: Tooling and Cost

The flexible molds have a shorter lifespan than the hardened steel dies used in conventional pressing. This, combined with the high cost of the specialized pressure vessels, makes the initial investment and per-part cost higher.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process depends entirely on the component's required performance, complexity, and production volume.

- If your primary focus is high-performance and absolute reliability: Isostatic pressing, particularly HIP, is the definitive choice for critical applications like aerospace components or medical implants where maximum density is non-negotiable.

- If your primary focus is producing complex shapes: Cold Isostatic Pressing (CIP) offers unparalleled design freedom for parts like intricate nozzles, tubes, and insulators that cannot be formed with simple directional pressure.

- If your primary focus is cost-effective mass production of simple shapes: Traditional uniaxial pressing remains the superior choice for high-volume, low-complexity items like tiles or basic dinnerware.

Ultimately, isostatic pressing is the premier engineering solution for creating uniform, high-density ceramic components with demanding geometries.

Summary Table:

| Aspect | Cold Isostatic Pressing (CIP) | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Temperature | Room Temperature | High Temperature (Simultaneous Sintering) |

| Key Benefit | Complex Shapes & Design Freedom | Near 100% Density & No Porosity |

| Common Applications | Refractory Nozzles, Insulators, Tubes | Aerospace Components, Medical Implants |

Need to produce high-performance ceramic components with complex geometries and uniform density?

KINTEK specializes in providing the advanced lab equipment and consumables necessary for developing and testing materials using methods like isostatic pressing. Whether you are researching new ceramic formulations or scaling up production for critical applications, our solutions support the precision and reliability your laboratory demands.

Contact our experts today to discuss how we can help you achieve superior material performance.

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Warm Isostatic Press for Solid State Battery Research

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why Use an Isostatic or High-Precision Hydraulic Press for Li/LLZO/Li Batteries? Master Solid-State Interfaces

- What are the disadvantages of cold working process? Key Limitations in Metal Forming

- What is the difference between wet bag and dry bag isostatic pressing? Flexibility vs. High-Volume Production

- Why is isostatic pressing better than regular uniaxial pressing when manufacturing ceramics? Achieve Superior Density and Complex Shapes

- What is the cold isostatic press process? Create Uniform, High-Integrity Parts

- What are the key functions of HIP equipment in ODS ferritic steel consolidation? Achieving 99.0% Density

- What role does an industrial-grade high-pressure manual screw pump play in an HHIP system? Achieve Precise Densification

- What are the different types of cold isostatic pressing? Wet-Bag vs. Dry-Bag for Your Production Needs