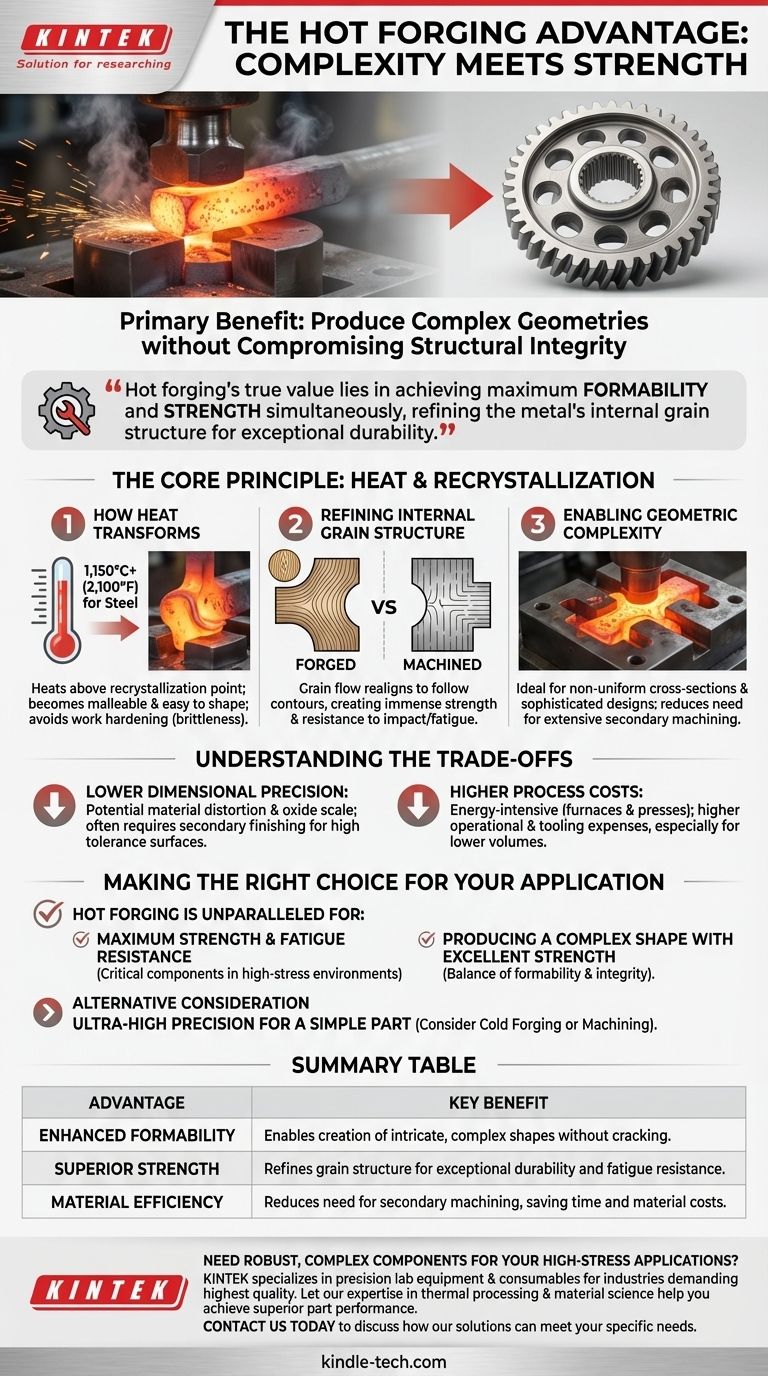

The primary advantage of hot forging is its unique ability to produce parts with complex geometries without compromising the material's structural integrity. By heating the metal above its recrystallization temperature, it becomes significantly more ductile and easier to shape, allowing for intricate designs that would be difficult or impossible to create through other high-strength manufacturing methods.

Hot forging's true value lies in achieving maximum formability and strength simultaneously. While other processes might offer one or the other, hot forging refines the metal's internal grain structure as it forms complex shapes, resulting in a final product that is both geometrically intricate and exceptionally durable.

The Core Principle: Heat and Recrystallization

How Heat Transforms the Material

Hot forging involves heating a metal workpiece, such as steel or titanium, to a temperature above its recrystallization point—often exceeding 1,150°C (2,100°F) for steel.

At this temperature, the metal does not melt. Instead, it enters a plastic-like state, making it far more malleable and easier to shape with compressive force from a press or hammer.

This process avoids work hardening, a phenomenon where deforming metal at lower temperatures increases its hardness but reduces its ductility, making it brittle and prone to cracking under stress.

Refining the Internal Grain Structure

The true genius of forging lies in what happens at a microscopic level. Like the grain in a piece of wood, metal has an internal grain flow.

During the hot forging process, the compressive forces realign this grain flow to follow the contours of the part. This continuous, unbroken grain structure creates a component with immense strength, ductility, and resistance to impact and fatigue.

By contrast, processes like machining cut through these grains, creating weak points, while casting produces a random, and therefore weaker, grain structure.

Enabling Geometric Complexity

Because the heated material deforms so easily, hot forging is ideal for producing parts with non-uniform cross-sections and sophisticated designs.

The process allows the metal to fill the intricate details of the forging die completely. This capability often reduces or eliminates the need for extensive secondary machining, saving both time and material costs for complex components.

Understanding the Trade-offs

Lower Dimensional Precision

The intense heat and subsequent cooling involved in hot forging can cause some material distortion and create a layer of oxide scale on the surface.

As a result, hot forged parts generally have looser tolerances and a rougher surface finish compared to cold forged or machined parts. A secondary machining step is often required for surfaces that demand high precision.

Higher Process Costs

Hot forging is an energy-intensive process. The need for large furnaces to heat the workpieces and powerful presses to shape them results in higher operational and tooling costs.

Additionally, specialized handling and quenching fixtures may be required, adding to the overall expense, particularly for lower-volume production runs.

Material Limitations

While versatile, not all metals are suitable for hot forging. The process requires careful control over temperature to avoid adverse metallurgical changes.

Precise thermal management is critical to prevent issues like overheating, which can degrade the material's properties, or surface oxidation, which can affect the final part's quality.

Making the Right Choice for Your Application

Choosing a manufacturing process requires balancing the demands of your design with the inherent strengths and weaknesses of each method. Hot forging is a powerful option when the right conditions are met.

- If your primary focus is maximum strength and fatigue resistance: Hot forging is unparalleled for critical components in high-stress environments, such as automotive gears, engine components, and aerospace structural parts.

- If your primary focus is producing a complex shape with excellent strength: Hot forging is the ideal choice, offering a balance of formability and structural integrity that casting cannot match.

- If your primary focus is ultra-high precision for a simple part: You may want to consider cold forging or machining, as hot forging will likely require secondary finishing to meet very tight tolerances.

By understanding these principles, you can confidently select the process that delivers the optimal balance of strength, complexity, and cost your project demands.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Enhanced Formability | Enables creation of intricate, complex shapes without cracking. |

| Superior Strength | Refines grain structure for exceptional durability and fatigue resistance. |

| Material Efficiency | Reduces need for secondary machining, saving time and material costs. |

Need robust, complex components for your high-stress applications? KINTEK specializes in precision lab equipment and consumables, serving industries that demand the highest quality. Let our expertise in thermal processing and material science help you achieve superior part performance. Contact us today to discuss how our solutions can meet your specific laboratory and manufacturing needs.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Does brazing require higher temperatures than soldering? Yes, and here’s why it matters.

- What is a challenge associated with electroplating sensing films? Achieving Uniformity for Reliable Sensors

- What are the advantages of plastic pyrolysis process? Unlock Value from Waste Plastic

- What is the 20 40 60 rule in Rotavap? A Guide to Efficient and Safe Solvent Evaporation

- What is the difference between pyrolysis and catalytic cracking? A Guide to Process Selection

- Is physical vapour deposition top down or bottom up? Unpacking the Core Fabrication Method

- What are the advantages of using a gas-phase reaction device with reflux condensation for g-C3N4 amination?

- What is the temperature range for pyrolysis oil? Optimize Yield and Quality for Your Process