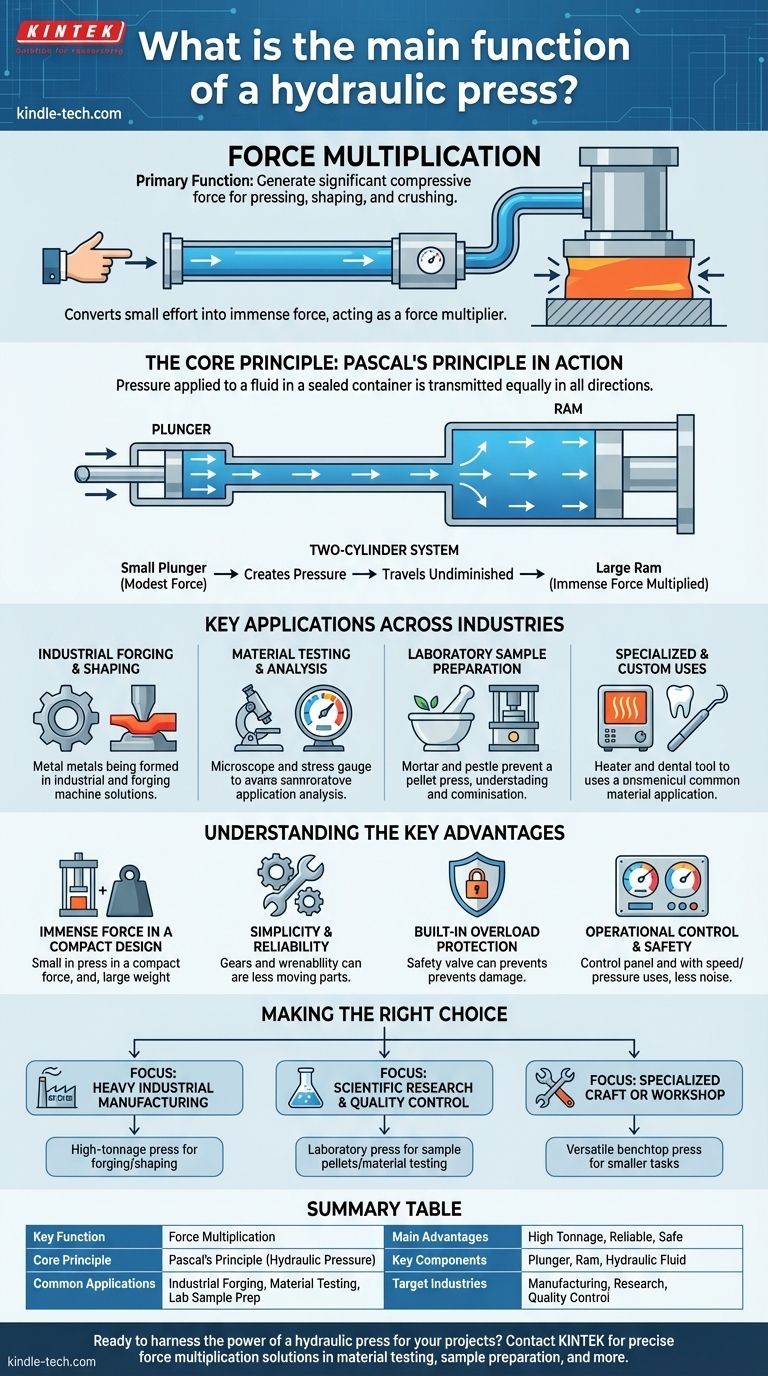

The primary function of a hydraulic press is to generate a significant amount of compressive force using the principle of hydraulic pressure. It acts as a force multiplier, transforming a small amount of effort applied to a small piston into an immense force exerted by a larger piston, or ram. This capability makes it indispensable for tasks requiring powerful pressing, shaping, or crushing.

At its core, a hydraulic press doesn't create energy; it converts and multiplies force. By applying Pascal's principle—that pressure in a confined fluid is transmitted equally in all directions—it allows for the generation of massive force with minimal initial effort, enabling a wide range of industrial and scientific applications.

The Core Principle: How Force is Multiplied

A hydraulic press operates on a simple yet powerful concept from fluid mechanics. Understanding this principle is key to appreciating its function and versatility.

Pascal's Principle in Action

The entire system works because of Pascal's Principle. This law states that when pressure is applied to a fluid in a sealed container, that pressure is distributed equally throughout the entire fluid.

A hydraulic press uses this to its advantage by connecting two cylinders of different sizes filled with hydraulic fluid, typically oil.

The Two-Cylinder System

The press consists of a small cylinder, called the plunger, and a much larger cylinder, called the ram.

When a modest force is applied to the plunger, it creates pressure in the fluid. This pressure travels undiminished through the fluid and exerts an equal amount of pressure per square inch on the much larger surface area of the ram.

Because the ram has a significantly larger area, the total force it exerts is proportionally multiplied, allowing it to perform tasks like forging steel or compressing materials with ease.

Key Applications Across Industries

The ability to generate immense and highly controllable force makes the hydraulic press a fundamental tool in numerous fields.

Industrial Forging and Shaping

In manufacturing, hydraulic presses are used to shape and form metal parts. They can press hot billets or ingots of metal into desired shapes, giving operators precise control over speed and pressure.

This control is crucial for creating complex geometries and ensuring the structural integrity of the final product.

Material Testing and Analysis

Engineers and scientists use hydraulic presses to test the strength and durability of materials. By applying a known amount of force, they can determine a material's breaking point or its response to high-stress conditions.

Laboratory Sample Preparation

In scientific and analytical laboratories, a hydraulic press is essential for preparing samples. It is commonly used to press powdered material into a solid, uniform pellet or a thin film.

This consistency is critical for analytical techniques like X-ray fluorescence (XRF) or Fourier-transform infrared spectroscopy (FTIR), which require a standardized sample form.

Specialized and Custom Uses

The adaptability of the hydraulic press has led to specialized versions. For example, hydraulic hot presses add temperature control to the process, while smaller, multi-purpose presses are staples in niche fields like dental laboratories.

Understanding the Key Advantages

Compared to mechanical or manual alternatives, the hydraulic press offers a distinct set of benefits that have made it a preferred choice for high-force applications.

Immense Force in a Compact Design

Hydraulic systems can generate exceptionally high tonnage (force) relative to their physical size. This allows for powerful machinery that requires less floor space than a mechanical press of equivalent power.

Simplicity and Reliability

The design of a hydraulic press is fundamentally simple, with fewer moving parts than complex mechanical systems. This leads to greater reliability, a longer lifespan for tooling, and lower maintenance requirements.

Built-in Overload Protection

A key safety and maintenance feature is inherent overload protection. A pressure relief valve prevents the system from exceeding its maximum rated pressure, protecting the operator and the machine from damage.

Operational Control and Safety

Hydraulic presses offer superior control over the ram's speed and pressure throughout its stroke. They also operate with significantly less noise than the impactful force of a mechanical press, creating a safer and more manageable work environment.

Making the Right Choice for Your Goal

The versatility of hydraulic presses means the ideal configuration depends entirely on your specific objective.

- If your primary focus is heavy industrial manufacturing: A high-tonnage press designed for forging and shaping materials with precision control is essential.

- If your primary focus is scientific research or quality control: A laboratory press for creating consistent sample pellets or testing material strength is the correct tool.

- If your primary focus is a specialized craft or workshop: A versatile benchtop press, like those used in dental labs, provides adaptability for a variety of smaller-scale tasks.

Ultimately, a hydraulic press is a master of force multiplication, making it a cornerstone of modern industry and science.

Summary Table:

| Key Function | Core Principle | Common Applications |

|---|---|---|

| Force Multiplication | Pascal's Principle (Hydraulic Pressure) | Industrial Forging, Material Testing, Lab Sample Prep |

| Main Advantages | Key Components | Target Industries |

| High Tonnage, Reliable, Safe | Plunger, Ram, Hydraulic Fluid | Manufacturing, Research, Quality Control |

Ready to harness the power of a hydraulic press for your projects?

Whether you're in industrial manufacturing, scientific research, or quality control, KINTEK's hydraulic presses deliver the precise force multiplication you need. Our lab equipment and consumables are designed for reliability, safety, and superior performance in tasks like material testing, sample preparation, and more.

Contact us today to find the perfect hydraulic press solution for your specific requirements!

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why is a laboratory hot press necessary for the production of plastic crystal polymer electrolyte reinforced membranes?

- How does a laboratory hot press improve the microscopic structure of polymer-ceramic composite cathodes? | KINTEK

- What are the advantages of using a hot press for Li7P2S8I0.5Cl0.5? Boost Conductivity with Precision Densification

- What role does a laboratory plate hot press play in the vulcanization and molding of fluorosilicone rubber (F-LSR)?

- Why is a laboratory hot press required for Oxygen Depolarized Cathodes? Ensure Precision Molding and Conductivity.