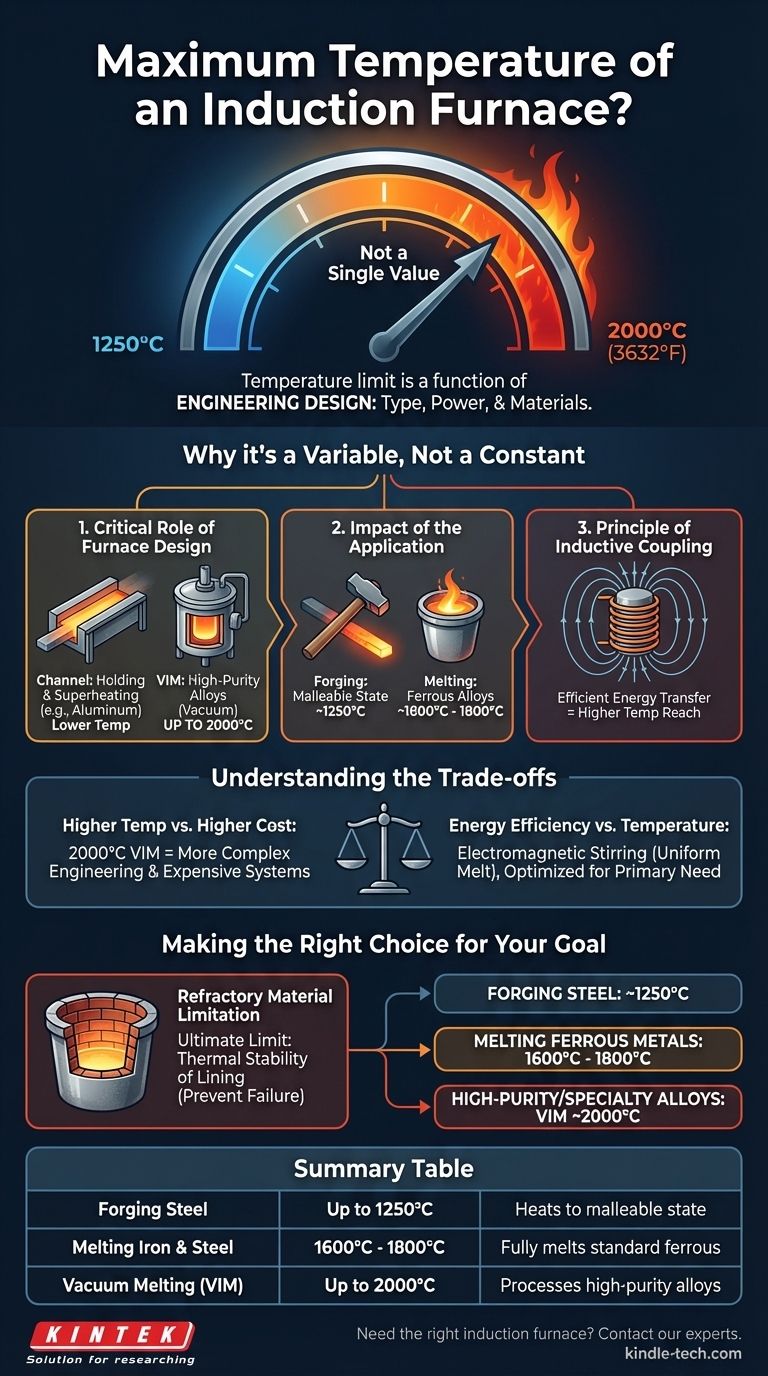

The maximum temperature of an induction furnace is not a single value but depends entirely on its design and intended application. While standard furnaces for forging and melting operate between 1250°C and 1800°C, highly specialized vacuum induction furnaces can reach temperatures as high as 2000°C (3632°F).

The key takeaway is that an induction furnace's temperature limit is a function of its engineering design—specifically its type, power, and the materials it's built from—rather than a fundamental physical limit of the induction heating principle itself.

Why "Maximum Temperature" Is a Variable, Not a Constant

Thinking of a furnace's maximum temperature as a single specification is a common mistake. In reality, it's the result of a system designed for a specific task. The temperature it can achieve is dictated by several interconnected factors.

The Critical Role of Furnace Design

Different induction furnaces are built for vastly different purposes, which directly impacts their temperature capabilities.

A channel induction furnace, for example, is often used for holding and superheating metals with lower melting points, like aluminum or cast iron, and is not designed for extreme temperatures.

In contrast, a vacuum induction melting (VIM) furnace is engineered for processing high-purity or reactive alloys. The vacuum environment prevents oxidation and contamination, allowing it to safely and effectively reach temperatures of 2000°C.

The Impact of the Application

The required temperature is determined by the job at hand. A furnace is only as hot as it needs to be for its specific process.

For forging steel, the goal is to make the metal malleable, not to melt it. Therefore, furnaces designed for this task typically operate up to 1250°C.

For melting iron and steel alloys, much higher temperatures are required. These furnaces are commonly rated for 1600°C to 1800°C to ensure the charge becomes fully molten.

The Principle of Inductive Coupling

The efficiency of the energy transfer from the coil to the metal (the "charge") is known as inductive coupling.

This process works like a transformer. The furnace's coil is the primary winding, and the metal charge itself acts as the secondary winding. A strong magnetic field induces powerful eddy currents in the metal, generating immense heat very quickly.

Better coupling means more efficient energy transfer, which allows the furnace to reach and maintain higher temperatures more effectively.

Understanding the Trade-offs

Choosing or specifying an induction furnace involves balancing capability with cost and complexity. There is no one-size-fits-all solution.

Higher Temperature vs. Higher Cost

Achieving extreme temperatures requires more sophisticated engineering. A 2000°C vacuum furnace is an order of magnitude more complex and expensive than a standard 1600°C melting furnace due to the vacuum systems, advanced power supplies, and specialized controls required.

Energy Efficiency vs. Temperature

The electromagnetic stirring effect created by the induction field is a unique benefit, ensuring a uniform temperature and chemical composition in the melt.

However, a furnace optimized for peak temperature may not be the most energy-efficient for simply holding metal at a lower temperature. The design must match the primary operational need.

The Limitation of Refractory Materials

Every induction furnace is lined with a refractory material—a ceramic crucible or lining that can withstand extreme heat and contain the molten metal.

The ultimate temperature limit of any furnace is governed by the thermal stability of this lining. Pushing the furnace beyond the refractory's rating will lead to rapid degradation and catastrophic failure.

Making the Right Choice for Your Goal

The correct question is not "how hot can it get," but "how hot do I need it to be?" Your specific application dictates the required performance.

- If your primary focus is forging steel: A furnace designed to reliably reach and hold temperatures around 1250°C is the correct tool.

- If your primary focus is melting standard ferrous metals: You need a robust melting furnace capable of operating in the 1600°C to 1800°C range.

- If your primary focus is producing high-purity, reactive, or specialty alloys: A vacuum induction furnace with a 2000°C capability is the necessary investment.

Ultimately, matching the furnace's capabilities to your specific material and process is the key to an efficient, safe, and successful operation.

Summary Table:

| Application | Typical Temperature Range | Key Characteristics |

|---|---|---|

| Forging Steel | Up to 1250°C | Heats metal to a malleable state without melting |

| Melting Iron & Steel | 1600°C - 1800°C | Fully melts standard ferrous alloys |

| Vacuum Melting (VIM) | Up to 2000°C | Processes high-purity, reactive alloys in a vacuum |

Need the right induction furnace for your specific temperature requirements?

At KINTEK, we specialize in providing precision lab equipment, including induction furnaces tailored for forging, melting, and high-purity applications. Our experts will help you select a furnace that matches your material and process goals—ensuring efficiency, safety, and performance.

Contact our team today to discuss your application and get a personalized solution!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting