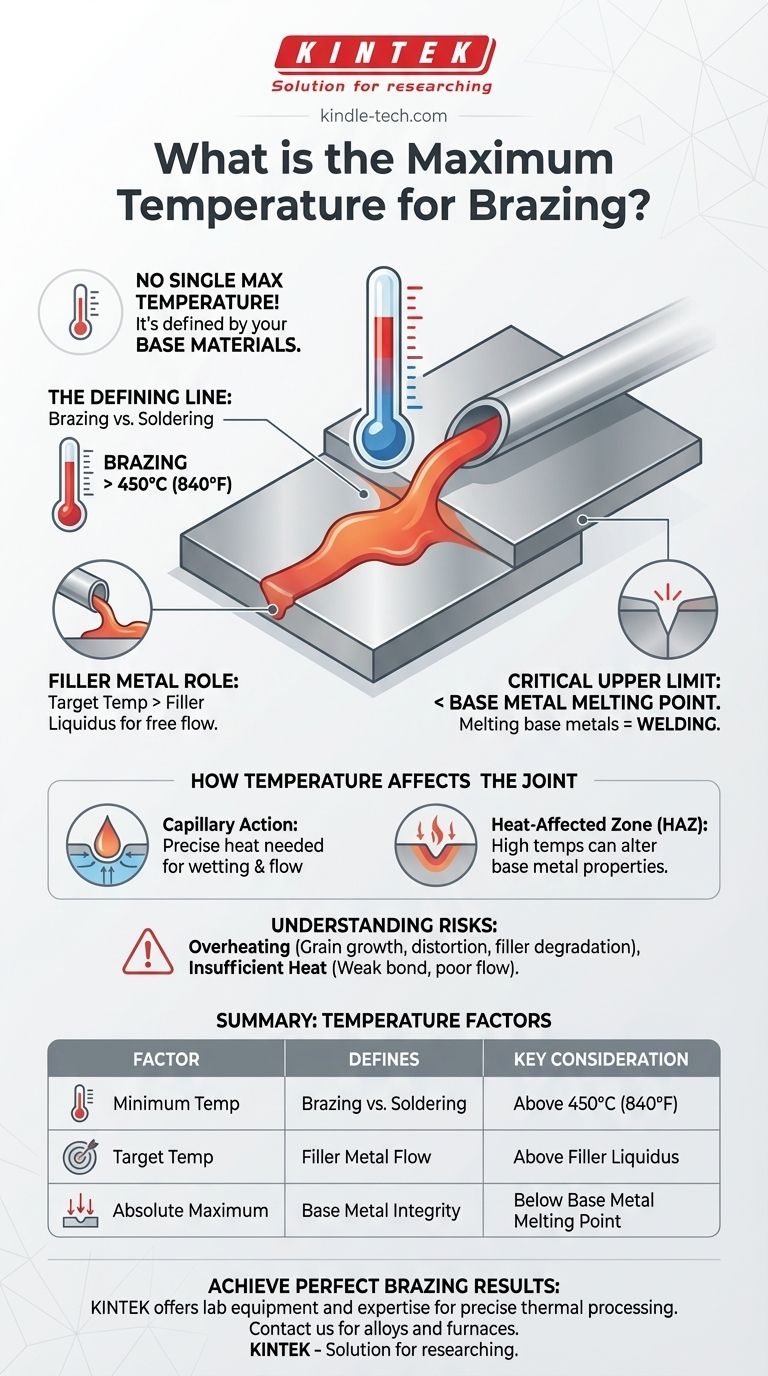

To be precise, there is no single maximum temperature for brazing. Instead, the maximum temperature is always defined by the materials you are joining. Brazing is fundamentally the process of joining metals using a filler metal that melts above 450°C (840°F) but always below the melting point of the base metals themselves.

The core principle of brazing is to heat the base metals enough for the filler to melt and flow, but never enough to melt the base metals. Therefore, the "maximum" temperature is dictated by the thermal tolerance of the parts being joined, not by the process itself.

The Defining Line: Brazing vs. Other Processes

To understand the temperature limits, it's essential to distinguish brazing from related thermal joining processes. The temperature range is what fundamentally defines the process.

The 450°C (840°F) Threshold

The official definition from the American Welding Society states that brazing happens above 450°C (840°F). Any similar process that uses a filler metal melting below this temperature is technically classified as soldering.

This threshold is the minimum temperature for a process to be considered brazing.

The Role of Filler Metal

The specific temperature you use is determined by the filler metal alloy. Each brazing alloy has a "melting range" defined by its solidus (the temperature at which it starts to melt) and its liquidus (the temperature at which it is fully liquid).

Your target brazing temperature is typically set slightly above the filler metal's liquidus temperature to ensure it flows freely.

The Critical Upper Limit: The Base Metal

The absolute maximum temperature for any brazing operation is the melting point of the base metals. If you reach the melting point of the parts you are joining, you are no longer brazing; you are welding.

This is the most critical rule in brazing, as melting the base metals compromises their structural integrity and defeats the purpose of the process.

How Temperature Affects the Joint

Controlling the temperature isn't just about avoiding a meltdown. Precise heat management is critical for creating a strong, reliable joint.

Capillary Action and Wetting

The primary mechanism for distributing the filler metal is capillary action, where the liquid alloy is drawn into the tight-fitting gap between the base metals.

Proper temperature is essential for this. If the heat is too low, the filler won't become fluid enough to "wet" the surfaces and flow. If it's too high, it can flow too quickly, leaving voids.

The Heat-Affected Zone (HAZ)

Even though brazing occurs below the base metal's melting point, the high temperatures still create a heat-affected zone (HAZ). This is an area where the microstructure and mechanical properties of the base metal can be altered.

For example, a previously heat-treated steel part can be softened (annealed) if the brazing temperature is too high or held for too long, weakening the final assembly.

Understanding the Trade-offs and Risks

Choosing the right temperature involves balancing the needs of the filler metal against the limitations of the base metal. Mismanaging this balance introduces significant risks.

Risk of Overheating the Base Metals

The most common failure mode is overheating. This can cause grain growth in the metal, making it brittle, or lead to distortion and warping of precision parts. For materials like hardened tool steels, overheating can completely destroy their engineered properties.

Filler Metal Degradation

Excessive heat can damage the filler metal itself. Some alloys contain elements with low boiling points, such as zinc or cadmium. Overheating can cause these elements to vaporize or "burn off," which alters the filler's chemical composition and can release hazardous fumes.

Insufficient Heat and a Weak Bond

Conversely, failing to reach the proper working temperature for the filler metal results in a poor joint. The filler may clump without flowing, fail to adhere to the base metals, and create a bond with little to no mechanical strength.

Making the Right Choice for Your Goal

The ideal brazing temperature is a carefully controlled window specific to your filler alloy and base materials. To ensure a successful joint, focus on the specific demands of your project.

- If your primary focus is joining heat-sensitive or heat-treated parts: Select a brazing alloy with the lowest possible working temperature to minimize the impact on the base metal's properties.

- If your primary focus is bridging larger gaps or creating fillets: Choose an alloy with a wider melting range (slushy state) and carefully control the heat to manipulate the filler metal as it solidifies.

- If your primary focus is maximum joint strength for materials like steel or carbides: Select a high-strength filler (like a nickel-silver or silver alloy) and ensure the base metals are heated uniformly to the filler's ideal working temperature for proper wetting and flow.

Ultimately, successful brazing is a precise balancing act: hot enough to activate the filler metal, but cool enough to preserve the integrity of the base materials.

Summary Table:

| Factor | Defines | Key Consideration |

|---|---|---|

| Minimum Temperature | Brazing vs. Soldering | Must be above 450°C (840°F) |

| Target Temperature | Filler Metal Flow | Set above the filler's liquidus point |

| Absolute Maximum | Base Metal Integrity | Must stay below the base metal's melting point |

Achieve perfect brazing results every time. Selecting the right temperature is critical for joint strength and base metal integrity. KINTEK specializes in providing the lab equipment and consumables necessary for precise thermal processing. Our experts can help you select the ideal brazing alloys and furnaces for your specific materials and application requirements. Contact our team today to discuss how we can support your laboratory's brazing and joining needs.

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What is meant by inert atmosphere? A Guide to Preventing Oxidation & Ensuring Safety

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2

- How do you make an inert atmosphere? Master Safe, Pure Processes with Inerting

- What is an inert atmosphere heat treatment? Protect Your Metals from Oxidation & Decarburization