The core of the electric arc furnace (EAF) melting process is the strategic use of high-power electric arcs to convert solid metal scrap into a molten bath. This is not simply a brute-force heating method; it involves a controlled sequence where operators first establish a stable arc shielded by the scrap itself, and only then increase the voltage to accelerate the meltdown efficiently.

The EAF process is defined by its two-stage approach: first, creating a protected, stable arc by boring electrodes into the scrap, and second, maximizing energy transfer by increasing voltage and immersing the electrodes for a rapid, controlled melt.

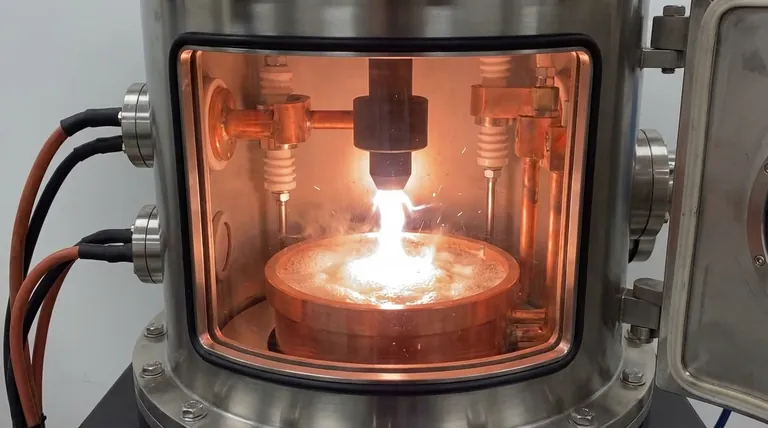

The EAF Melting Sequence: From Scrap to Molten Steel

The journey from a furnace full of cold scrap to a ready-to-tap heat of liquid steel follows a precise and dynamic sequence. Each step is designed to maximize heating efficiency while protecting the furnace itself from the extreme temperatures involved.

The Initial Bore-In

The process begins by lowering massive graphite electrodes toward the pile of charged scrap metal. A high current is applied, creating a powerful electric arc that jumps from the electrode tip to the nearest piece of scrap. This initial arc is unstable and radiates immense heat in all directions.

Shielding the Arc

During the initial phase, the electrodes effectively bore a path down into the scrap pile. The surrounding solid scrap acts as a natural shield, absorbing the arc's intense radiation. This shielding is critical for protecting the furnace's water-cooled walls and roof from damage.

Maximizing Power Input

Once the arcs are sufficiently shielded by the surrounding scrap, it is safe to increase the power. Operators will increase the voltage, which lengthens the arc and dramatically increases the rate of energy transfer. This is the primary "meltdown" phase where the bulk of the scrap is liquefied.

Forming the Molten Pool

As scrap melts, it drips down and forms a liquid pool, or "hot heel," at the bottom of the furnace. This growing bath of molten metal becomes the new target for the electric arcs, providing a more stable and conductive medium than the solid scrap.

Deep Bathing for Efficiency

To complete the melt, operators will lower the electrodes so their tips are submerged in the slag layer that floats on top of the molten steel. This is known as deep bathing or a "foamy slag" practice. This technique stabilizes the arc, transfers heat directly and efficiently into the molten bath, and further shields the furnace refractory from radiation, speeding up the final meltdown of any remaining scrap. A typical melt cycle, or tap-to-tap time, can be as short as 20-30 minutes in modern, high-powered furnaces.

Understanding the Trade-offs

While the EAF is a fast and flexible steelmaking technology, it operates in an extreme environment that presents significant operational challenges and costs.

Extreme Energy Consumption

The EAF is one of the largest single electrical loads on any power grid. Managing electricity costs, especially during peak demand periods, is a primary concern for any EAF operator.

Electrode Consumption

The graphite electrodes are not permanent. The intense heat of the arc causes them to slowly vaporize and break down, making them a significant and costly consumable in the steelmaking process.

Refractory Wear

The inner lining of the furnace, made of heat-resistant refractory bricks, is under constant attack from thermal stress, chemical reactions with slag, and the intense arc radiation. Proper shielding and deep bathing practices are essential to prolong refractory life, but frequent maintenance and relining are unavoidable costs.

Making the Right Choice for Your Goal

Understanding the EAF melting process allows for better control over the balance between production speed and operational cost.

- If your primary focus is speed and throughput: The key is to establish a shielded arc as quickly as possible to allow for the use of high-voltage profiles that maximize power input and accelerate the meltdown.

- If your primary focus is operational efficiency: Meticulous control of electrode positioning to create a deep, foamy slag bath is essential for minimizing energy loss, reducing electrode consumption, and extending the life of the furnace lining.

Ultimately, mastering the EAF melting process is a continuous exercise in balancing raw power with precise control.

Summary Table:

| Stage | Key Action | Primary Goal |

|---|---|---|

| Initial Bore-In | Lower electrodes to create an arc on scrap. | Establish an initial, unstable arc. |

| Shielding the Arc | Use surrounding scrap to absorb radiation. | Protect furnace walls and roof from damage. |

| Maximizing Power | Increase voltage to lengthen the arc. | Accelerate the primary meltdown phase. |

| Forming Molten Pool | Collect liquid metal as a 'hot heel' at the furnace bottom. | Create a stable, conductive bath for the arc. |

| Deep Bathing | Submerge electrode tips in the slag layer. | Stabilize the arc and transfer heat efficiently to complete the melt. |

Master the balance between speed and cost-efficiency in your melting operations. KINTEK specializes in the high-performance lab equipment and consumables essential for advanced metallurgical processes. Our expertise supports the precise control needed for optimal EAF operation. Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and drive your research forward.

Visual Guide

Related Products

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is RF magnetron sputtering? A Guide to Depositing Insulating Thin Films

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What are the different melting methods? A Guide to Choosing the Right Industrial Furnace