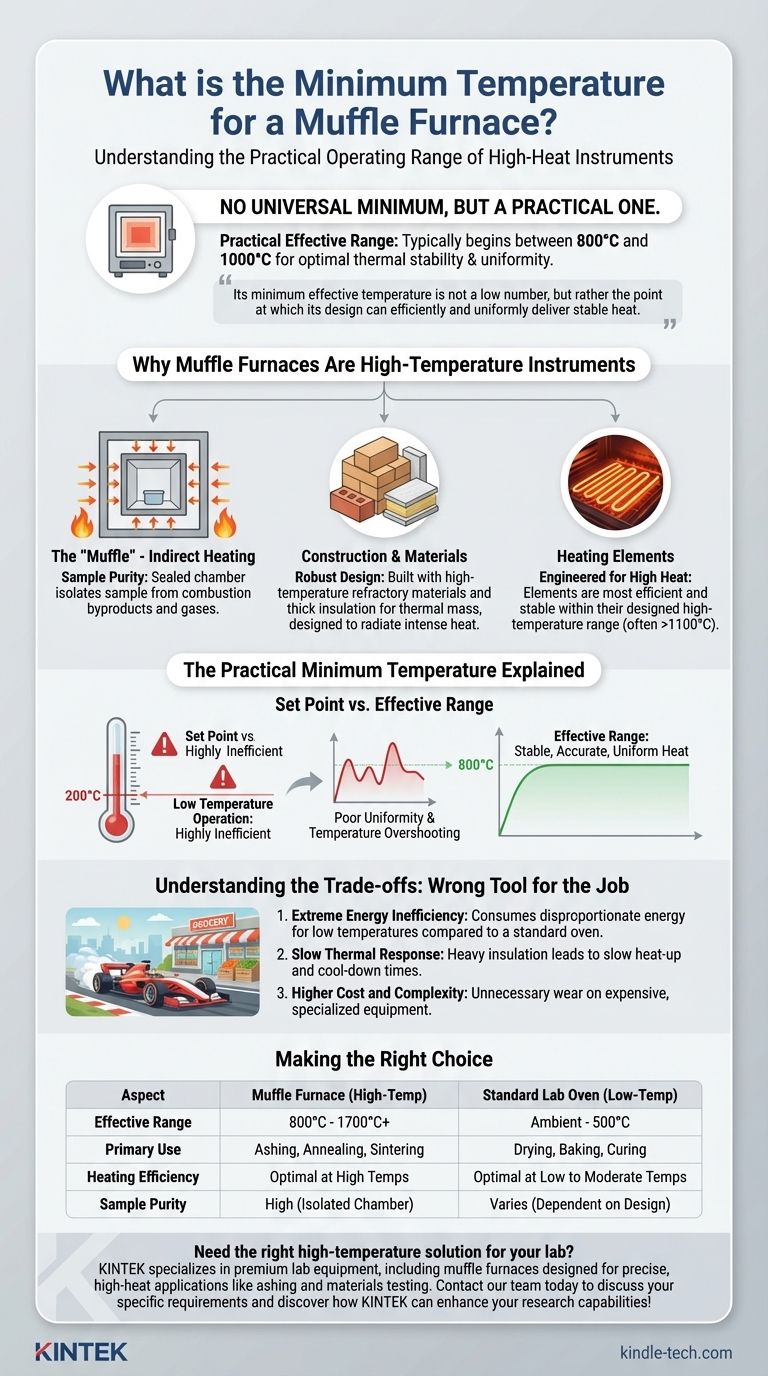

While there is no universal minimum temperature for all muffle furnaces, they are fundamentally high-heat instruments. Their practical and efficient operating range typically begins between 800°C and 1000°C, as their design is optimized for thermal stability and uniformity at these elevated temperatures.

A muffle furnace is engineered specifically for high-temperature processes that demand sample purity. Its minimum effective temperature is not a low number, but rather the point at which its design can efficiently and uniformly deliver stable heat.

Why Muffle Furnaces Are High-Temperature Instruments

Understanding the core design of a muffle furnace explains why it is unsuited for low-temperature applications. Its entire construction is geared toward achieving and maintaining extreme heat while protecting the sample.

The Principle of Indirect Heating

A true muffle furnace features a sealed inner chamber (the "muffle") that holds the material being heated.

The heating elements or flames are outside this chamber. This design prevents combustion byproducts, gases, and other contaminants from coming into contact with the sample.

This separation is crucial for processes like ashing, annealing, or materials research where sample purity is paramount.

Construction and Materials

To withstand temperatures often exceeding 1100°C, these furnaces are built with robust, high-temperature refractory materials and thick insulation.

These materials create significant thermal mass, meaning they are designed to hold and radiate intense heat efficiently.

The Role of Heating Elements

Modern electric muffle furnaces use specialized heating elements engineered to operate for long periods at very high temperatures.

These elements are most efficient and stable within their designed high-temperature range and may not provide uniform heating at lower setpoints.

The Practical Minimum Temperature Explained

While you might be able to set a low temperature on the controller, the furnace will not operate effectively or efficiently. The "minimum temperature" is therefore a practical limit, not a technical one.

The Problem with Low-Temperature Operation

Operating a muffle furnace at low temperatures (e.g., 200°C) is highly inefficient. The massive insulation and high-power elements are overkill.

This can lead to poor temperature uniformity within the chamber, where some areas are hotter than others, and significant temperature overshooting as the controller struggles to regulate the powerful elements.

Setpoint vs. Effective Range

It is critical to distinguish between the temperature you can set and the furnace's effective operating range.

The effective range is where the furnace can provide stable, accurate, and uniform heat as intended by its design. For most muffle furnaces, this range starts in the high hundreds of degrees Celsius.

Understanding the Trade-offs

Using a muffle furnace for a low-temperature task is like using a race car for a trip to the grocery store. It works, but it's the wrong tool for the job.

Extreme Energy Inefficiency

A furnace designed to hold 1200°C will consume a disproportionate amount of energy to maintain a low temperature like 150°C.

A standard laboratory oven would perform the same task with a fraction of the power consumption.

Slow Thermal Response

The heavy insulation and high thermal mass mean muffle furnaces heat up and cool down very slowly.

This makes them impractical for processes that require rapid temperature cycling or quick access to the sample at lower temperatures.

Higher Cost and Complexity

Muffle furnaces are specialized, expensive instruments. Using them for tasks that could be accomplished by a simpler, cheaper laboratory oven leads to unnecessary wear on a high-value piece of equipment.

Making the Right Choice for Your Goal

Selecting the correct heating instrument is crucial for efficiency, accuracy, and cost-effectiveness.

- If your primary focus is high-temperature processing (above 800°C) with sample isolation: The muffle furnace is the ideal instrument, designed precisely for this purpose.

- If your primary focus is drying, baking, or curing at moderate temperatures (100°C - 500°C): A standard laboratory or industrial oven is far more efficient and provides better control.

- If your primary focus is maintaining precise, low temperatures (ambient to 100°C): A dedicated incubator or drying oven offers superior stability and performance in this range.

Ultimately, a muffle furnace's value is defined by its mastery of high temperatures, and matching your tool to your task ensures reliable and efficient results.

Summary Table:

| Aspect | Muffle Furnace (High-Temp) | Standard Lab Oven (Low-Temp) |

|---|---|---|

| Effective Range | 800°C - 1700°C+ | Ambient - 500°C |

| Primary Use | Ashing, Annealing, Sintering | Drying, Baking, Curing |

| Heating Efficiency | Optimal at high temperatures | Optimal at low to moderate temperatures |

| Sample Purity | High (isolated chamber) | Varies (dependent on design) |

Need the right high-temperature solution for your lab? KINTEK specializes in premium lab equipment, including muffle furnaces designed for precise, high-heat applications like ashing and materials testing. Our experts can help you select the ideal furnace to ensure thermal stability, sample purity, and energy efficiency. Contact our team today to discuss your specific laboratory requirements and discover how KINTEK can enhance your research capabilities!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the use of muffle furnace in food industry? Essential for Accurate Food Ash Analysis

- How does the calcination process work? Master Thermal Decomposition for Material Purification

- What happens after calcination? A Guide to Material Transformation and Next Steps

- How does heat affect material strength? Understanding Thermal Degradation and Creep Failure

- What is the temperature of furnace exhaust? A Key Indicator of Efficiency and Safety