In metallurgy, a muffle furnace is an essential tool for any process requiring precise, high-temperature heating in a controlled, contaminant-free environment. Its primary uses include heat treatment processes like tempering, creating and testing metal alloys, and conducting analytical tests such as drying precipitates or determining the flammability of materials.

A muffle furnace's value in metallurgy is not just its ability to reach high temperatures, but its core design. The internal chamber, or "muffle," isolates the metal from the direct heat source, preventing contamination from combustion byproducts and ensuring a uniform thermal environment for predictable results.

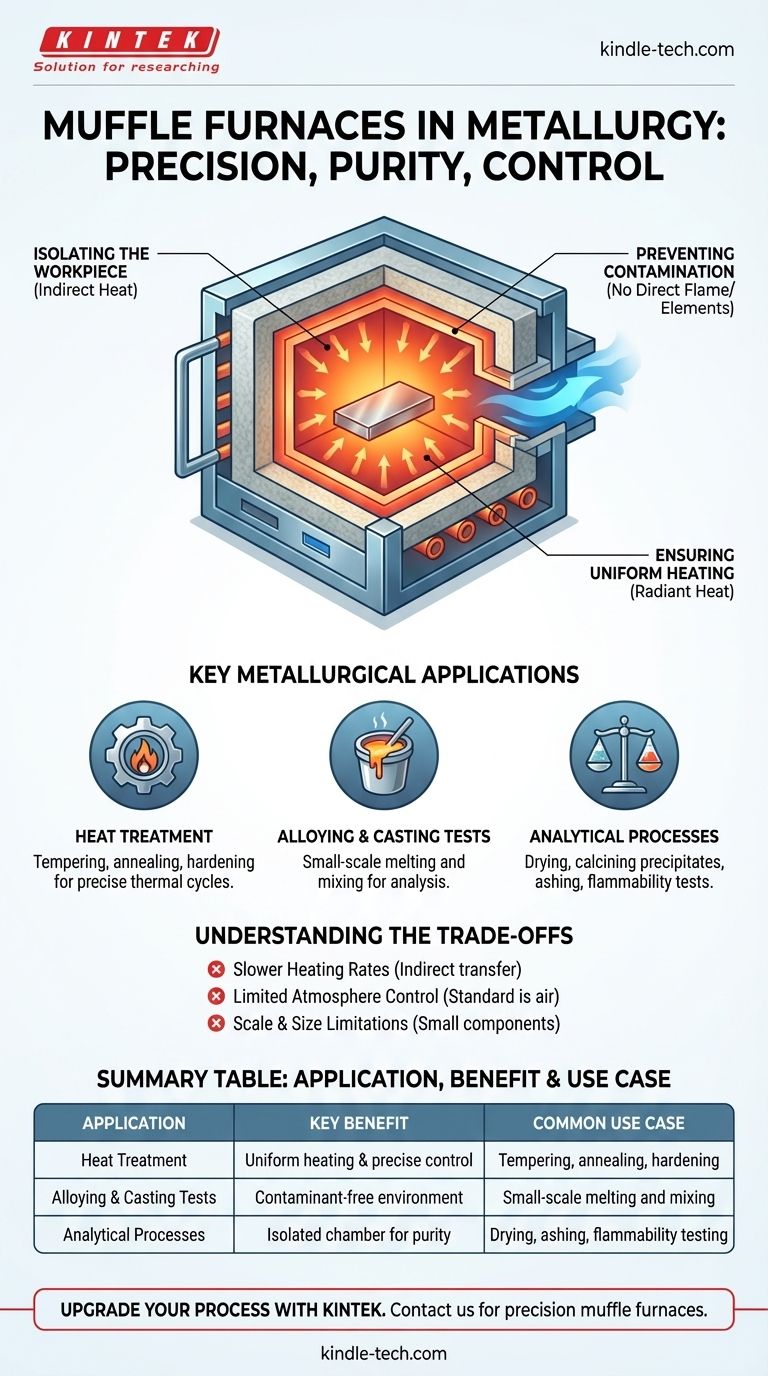

The Core Principle: Why a "Muffle" Is Crucial

The defining feature of this furnace is the "muffle"—a separate, enclosed chamber typically made of a high-temperature ceramic. This design is fundamental to its metallurgical applications.

Isolating the Workpiece

The muffle acts as a barrier, shielding the material inside from direct contact with the heating elements or flames. Heat is transferred indirectly, primarily through radiation and convection within the chamber.

Preventing Contamination

For many metallurgical processes, purity is paramount. Direct exposure to combustion gases (in a gas-fired furnace) or degrading electric elements can introduce impurities that react with the metal, altering its chemical composition and mechanical properties. The muffle prevents this contamination.

Ensuring Uniform Heating

Because the muffle radiates heat from all its interior surfaces, it creates a highly uniform temperature zone around the workpiece. This uniformity is critical for consistent heat treatment, ensuring that an entire component achieves the same metallurgical structure.

Key Metallurgical Applications

The principle of isolated, uniform heating makes the muffle furnace ideal for several specific tasks in both production and laboratory settings.

Heat Treatment

Processes like tempering, annealing, and hardening rely on precise thermal cycles to alter a metal's microstructure, thereby changing its hardness, ductility, and strength. A muffle furnace provides the exact temperature control and stability required for these transformations.

Alloying and Casting Tests

When developing new metal alloys or testing casting methods on a small scale, a muffle furnace allows metallurgists to melt and mix constituents at precise temperatures. This ensures the resulting sample has the desired phase and properties for analysis.

Analytical Processes

The furnace is widely used for preparing samples for analysis. This includes drying and calcining precipitates to remove moisture and volatile compounds, leaving behind a pure substance for weighing. It is also used in high-temperature flammability tests and ashing, where a material is burned to determine its inorganic content.

Understanding the Trade-offs

While incredibly useful, the muffle furnace is not the right tool for every thermal task. Understanding its limitations is key to using it effectively.

Slower Heating Rates

Because heat is transferred indirectly, muffle furnaces generally have slower heating rates compared to direct-fired or induction furnaces. This can be a disadvantage in high-volume production environments.

Atmosphere Control

A standard muffle furnace operates with an air atmosphere. While this is sufficient for many tasks, processes requiring a specific inert (e.g., argon, nitrogen) or reactive atmosphere need a specialized retort or vacuum furnace.

Scale and Size

Muffle furnaces are most common in laboratories and workshops for smaller components or sample quantities. For processing very large parts or melting tons of metal, industrial-scale equipment like arc furnaces or large-batch ovens are necessary.

Making the Right Choice for Your Goal

To apply this knowledge, consider the primary objective of your thermal process.

- If your primary focus is precise heat treatment of components: A muffle furnace offers the uniform, contaminant-free environment needed to reliably alter metallurgical properties.

- If your primary focus is analytical testing or sample preparation: The isolated chamber of a muffle furnace is essential for preventing contamination and ensuring your results reflect the material's true characteristics.

- If your primary focus is high-volume melting or large-scale processing: You will likely need to investigate other furnace types, such as induction or arc furnaces, designed for greater capacity and speed.

Ultimately, understanding the muffle furnace is about recognizing the power of controlled, isolated heating in achieving metallurgical precision.

Summary Table:

| Application | Key Benefit | Common Use Case |

|---|---|---|

| Heat Treatment | Uniform heating & precise temperature control | Tempering, annealing, hardening of metals |

| Alloying & Casting Tests | Contaminant-free environment | Small-scale melting and mixing of metal alloys |

| Analytical Processes | Isolated chamber for purity | Drying precipitates, ashing, flammability testing |

Upgrade your metallurgical processes with KINTEK's precision muffle furnaces. Our lab equipment ensures contaminant-free, uniform heating for reliable heat treatment, alloy testing, and sample preparation. Contact us today to find the perfect furnace for your laboratory's needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Can two different materials have the same value of specific heat capacity? Unlocking the Science of Thermal Behavior

- What is a muffle furnace in food analysis? A Guide to Precise Mineral Content Measurement

- What temperature causes melting? Debinding vs. Melting in Metal Fabrication

- Does heat capacity affect melting point? Unraveling the Key Differences in Thermal Properties

- What is ramp rate and how does that affect a melting point measurement? Master the Key to Accurate Thermal Analysis