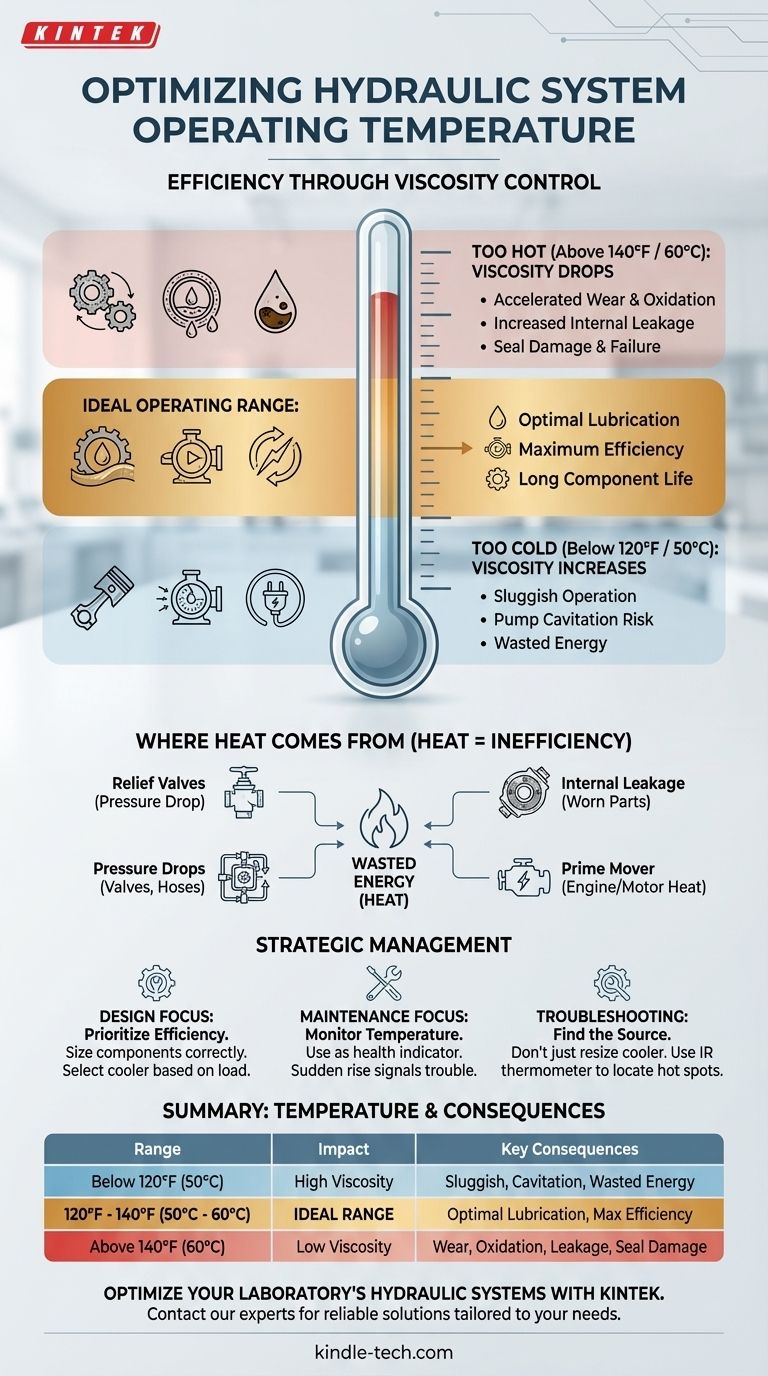

For a standard hydraulic system, the ideal operating temperature is a narrow window, typically between 120°F and 140°F (50°C to 60°C). While some systems are designed to tolerate temperatures up to 180°F (82°C), operating consistently at this upper limit drastically shortens the life of the fluid and system components. The optimal temperature is not a fixed number but a critical balance point for the fluid's viscosity.

Operating temperature is the primary indicator of a hydraulic system's efficiency. Excessive heat is not the root problem, but a symptom of wasted energy. Effective temperature management is fundamentally about controlling fluid viscosity to ensure proper lubrication, prevent premature wear, and guarantee predictable system performance.

Why Temperature Is a Critical Operating Factor

Temperature directly governs the viscosity of your hydraulic fluid. Viscosity—the fluid's resistance to flow—is arguably its most important property. The entire system is designed to operate within a specific viscosity range.

The Central Role of Fluid Viscosity

Hydraulic fluid must be thin enough to flow efficiently and minimize power loss, but thick enough to provide a lubricating film between moving parts and create effective seals within components like pumps, motors, and valves. The target viscosity is a careful compromise between these two states.

The Consequences of Running Too Hot

When the temperature rises, viscosity drops. The fluid becomes too thin. This creates several compounding problems:

- Reduced Lubrication: The lubricating film thins out, leading to accelerated metal-to-metal wear on critical components.

- Increased Internal Leakage: Thinner fluid bypasses internal seals more easily, reducing the efficiency of pumps and actuators. This means the pump must work harder to achieve the same output, generating even more heat.

- Accelerated Fluid Oxidation: High temperatures dramatically speed up the chemical breakdown of the oil, forming sludge and varnish that can clog filters and seize valves. As a rule of thumb, for every 18°F (10°C) increase above 140°F (60°C), the oil's service life is cut in half.

- Seal Damage: Hot oil can cause seals to harden, become brittle, and fail, leading to external leaks.

The Dangers of Running Too Cold

Conversely, when the temperature is too low, viscosity increases. The fluid becomes too thick, which can be just as damaging.

- Sluggish Operation: Components respond slowly, and cycle times increase.

- Increased Power Consumption: The pump must work significantly harder to push the thick fluid through the system, wasting energy.

- Pump Cavitation: Thick oil may not flow into the pump's suction side fast enough, causing cavitation—the formation and collapse of vapor bubbles—which is extremely destructive to the pump.

Where Does the Heat Come From?

Heat in a hydraulic system is a direct result of inefficiency. Every pressure drop that does not perform useful work (like lifting a load) is converted into heat. Understanding the sources is the first step to controlling temperature.

Heat as a Byproduct of Inefficiency

Think of heat as a tax on your system's power. Any restriction to flow or internal leakage forces the pump to generate more flow or pressure than is required for the work, and this wasted energy is dissipated as heat. A cool-running system is an efficient system.

Common Sources of Heat Generation

- Relief Valves: The single biggest source of heat is often fluid flowing across a relief valve, where the fluid's pressure energy is converted directly into heat.

- Pressure Drops: Every component creates a pressure drop, including valves, hoses, and filters. Poorly sized lines or unnecessarily complex circuits increase these drops.

- Internal Leakage: As components wear, internal leakage increases. A worn pump or cylinder will bypass more fluid, generating heat and reducing performance.

- The Prime Mover: The engine or electric motor driving the pump also radiates heat into the hydraulic system.

Understanding the Pitfalls and Trade-offs

Simply observing that a system is "hot" is not enough. An effective technical approach requires diagnosing the underlying cause and understanding the consequences of your solution.

The Mistake of Treating the Symptom

The most common mistake is to treat high heat by simply installing a larger cooler. While a cooler is necessary to dissipate heat, an oversized cooler can mask a serious underlying inefficiency, like a failing pump or a poorly set relief valve. You are treating the symptom (heat) instead of the disease (energy loss).

The Risk of Over-Cooling

It is possible to run a system too cold, especially in colder climates. Over-cooling leads to the high-viscosity problems mentioned earlier, like sluggishness and wasted energy. Many systems use a thermostatic bypass valve to route fluid around the cooler until the system reaches its minimum operating temperature.

The Impact of Fluid Selection

Not all hydraulic fluids are created equal. The Viscosity Index (VI) is a number that indicates how much the fluid's viscosity changes with temperature. A fluid with a high VI will maintain a more stable viscosity across a wider temperature range, making it more forgiving in systems with significant temperature swings.

How to Apply This to Your Project

Your strategy for temperature management depends on your role in the system's lifecycle.

- If your primary focus is design: Prioritize system efficiency to minimize heat generation from the start. Correctly size all lines and valves, and select a cooler based on the calculated heat load, not as an afterthought.

- If your primary focus is maintenance: Use operating temperature as a key health indicator. A sudden or gradual increase in normal operating temperature is a clear signal of developing inefficiency, such as component wear or a stuck valve.

- If your primary focus is troubleshooting an overheating system: Investigate the source of the inefficiency before resizing the cooler. Use an infrared thermometer to find hot spots and identify which component is generating the most heat.

Ultimately, precise temperature control is the key to unlocking a reliable, efficient, and long-lasting hydraulic system.

Summary Table:

| Temperature Range | Impact on System | Key Consequences |

|---|---|---|

| Below 120°F (50°C) | Fluid too thick (High Viscosity) | Sluggish operation, pump cavitation, wasted energy |

| 120°F - 140°F (50°C - 60°C) | Ideal Operating Range | Optimal lubrication, maximum efficiency, long component life |

| Above 140°F (60°C) | Fluid too thin (Low Viscosity) | Accelerated wear, fluid oxidation, internal leakage, seal damage |

Optimize Your Laboratory's Hydraulic Systems with KINTEK

Is your lab equipment's hydraulic performance suffering from temperature-related inefficiencies? KINTEK specializes in providing the precise lab equipment and consumables you need to maintain optimal operating conditions. Our expertise ensures your systems run cooler, last longer, and perform reliably, protecting your critical research and investments.

Contact our experts today for a consultation on reliable hydraulic solutions tailored to your laboratory's needs.

Visual Guide

Related Products

- 100L Chilling Circulator Cooling Water Circulator for Low Temperature Constant Temperature Reaction Bath Water Bath Cooling

- 80L Chilling Circulator Cooling Water Circulator for Water Bath Cooling and Low Temperature Constant Temperature Reaction Bath

- 5L Chilling Circulator Cooling Water Bath Circulator for Low Temperature Constant Temperature Reaction Bath

- 10L Chilling Circulator Cooling Water Bath Low Temperature Constant Temperature Reaction Bath

- 5L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- What is the effect of cooling rate on casting? Control Strength, Ductility, and Defects

- What factors affect the rate of cooling? Control Heat Transfer for Efficient Processes

- What is the cooling system of an induction furnace? Essential for Safe, Reliable Melting

- What is the effect of heat generated in hydraulic system? Prevent Costly Damage and Downtime

- What creates heat in a hydraulic system? Understanding Energy Loss and Pressure Drop