Excess heat is the single greatest threat to a hydraulic system's longevity and performance. The most immediate effect is a dangerous drop in the hydraulic oil's viscosity (its thickness), which compromises its ability to lubricate moving parts. This leads to accelerated wear on expensive components, degradation of seals and hoses, and a significant loss of overall system efficiency.

While some heat is an unavoidable byproduct of energy conversion, excessive heat is a clear symptom of inefficiency within the system. Understanding its destructive effects is the first step toward diagnosing the root cause and ensuring long-term reliability.

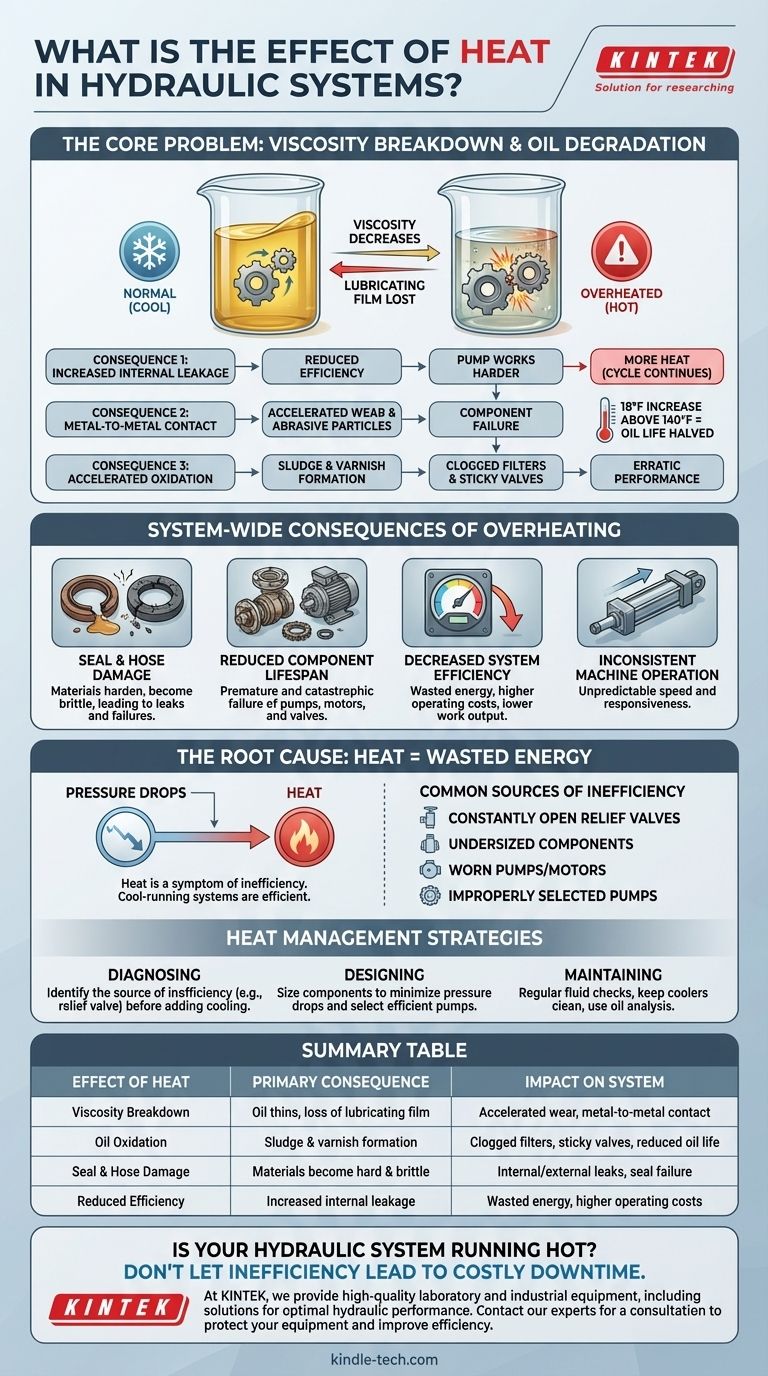

The Core Problem: How Heat Degrades Hydraulic Oil

The hydraulic fluid is the lifeblood of the system, and heat directly attacks its fundamental properties.

Viscosity Breakdown: The Primary Effect

As hydraulic oil gets hotter, its viscosity decreases, meaning it becomes thinner. The system is designed to operate within a specific viscosity range to both transmit power and lubricate components.

Operating a system with oil that is too thin is like running a car engine with water instead of oil. The protective fluid film between moving metal parts is lost.

The Consequence of Low Viscosity

When viscosity is too low, the lubricating film breaks down. This directly causes increased internal leakage in pumps, motors, and valves, reducing their efficiency.

More critically, it allows metal-to-metal contact, which generates abrasive particles and rapidly wears out precision components.

Accelerated Oxidation and Contamination

Heat acts as a catalyst, dramatically speeding up the oil's oxidation rate. For every 18°F (10°C) increase in temperature above 140°F (60°C), the oil's service life is cut in half.

Oxidation creates byproducts like sludge and varnish. These contaminants coat internal surfaces, clog filters, and cause valves to stick, leading to erratic system performance.

System-Wide Consequences of Overheating

The degradation of the oil triggers a cascade of failures throughout the entire hydraulic system.

Damage to Seals and Hoses

Most seals and hoses are made from synthetic elastomers that have specific temperature limits. Excessive heat causes these materials to become hard and brittle.

This loss of flexibility prevents them from sealing effectively, resulting in both internal and external leaks. A blown hose or failed cylinder seal is often a symptom of a chronic overheating problem.

Reduced Component Lifespan

The combination of poor lubrication (from low viscosity) and increased contamination (from oxidation) is devastating to components.

Pumps, motors, and valves experience accelerated wear, leading to premature and catastrophic failure. The cost of replacing these components is a major consequence of unmanaged heat.

Decreased System Efficiency

A hot, thin fluid increases internal leakage. This means for a given input power, less useful work is done. The pump must work harder and longer to achieve the same task, wasting energy.

This inefficiency creates a vicious cycle: wasted energy is converted into more heat, which further thins the oil, which causes more inefficiency.

Inconsistent Machine Operation

Changes in fluid viscosity affect the performance of control valves and actuators. As the system heats up, operators may notice that cylinders and motors slow down or become less responsive, leading to unpredictable machine behavior.

Understanding the Trade-offs: Heat Generation vs. System Design

Heat is not the root problem; it is a symptom of wasted energy. Understanding where this waste comes from is key to a reliable design.

Heat is a Byproduct of Inefficiency

Every hydraulic system experiences pressure drops. A pressure drop that does not perform useful work (like moving a cylinder) is converted directly into heat.

Therefore, the amount of heat generated is a direct measure of the system's inefficiency. A cool-running system is an efficient one.

Common Sources of Inefficiency

The primary sources of wasted energy include:

- Relief valves that are constantly open, dumping pressurized oil back to the tank.

- Undersized lines, fittings, and valves that create excessive flow resistance.

- Worn components (pumps, motors) with high internal leakage.

- Improperly selected pumps for the required duty cycle.

The Role of Coolers and Reservoirs

Reservoirs and heat exchangers (coolers) are designed to dissipate a certain amount of waste heat. However, they are often used as a band-aid.

If a system is fundamentally inefficient, it may generate more heat than the cooling circuit can handle. Simply adding a larger cooler does not fix the underlying problem of wasted energy.

A Practical Approach to Heat Management

Your strategy for managing heat depends on whether you are designing a new system or troubleshooting an existing one.

- If you are diagnosing an existing overheating problem: Focus on identifying the source of inefficiency—such as a constantly running relief valve or a worn pump—before simply adding a larger cooler.

- If you are designing a new hydraulic system: Size your components (lines, valves, reservoir) to minimize pressure drops and select an efficient pump for the required duty cycle.

- If your goal is routine maintenance: Regularly check fluid levels, keep heat exchangers clean, and use oil analysis to monitor viscosity and oxidation before they cause catastrophic failure.

By treating heat as a critical system indicator, you can proactively ensure the efficiency and reliability of your hydraulic equipment.

Summary Table:

| Effect of Heat | Primary Consequence | Impact on System |

|---|---|---|

| Viscosity Breakdown | Oil thins, losing lubricating film | Accelerated wear, metal-to-metal contact |

| Oil Oxidation | Sludge & varnish formation | Clogged filters, sticky valves, reduced oil life |

| Seal & Hose Damage | Materials become hard and brittle | Internal/external leaks, seal failure |

| Reduced Efficiency | Increased internal leakage | Wasted energy, higher operating costs |

Is your hydraulic system running hot? Don't let inefficiency lead to costly downtime and component failure.

At KINTEK, we specialize in providing high-quality laboratory and industrial equipment, including solutions for monitoring and maintaining optimal hydraulic system performance. Our expertise can help you identify inefficiencies and select the right components to keep your systems running cool and reliable.

Contact our experts today for a consultation on how to protect your hydraulic equipment and improve operational efficiency.

Visual Guide

Related Products

- 100L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 100L Chilling Circulator Cooling Water Circulator for Low Temperature Constant Temperature Reaction Bath Water Bath Cooling

- 10L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 80L Chilling Circulator Cooling Water Circulator for Water Bath Cooling and Low Temperature Constant Temperature Reaction Bath

- 5L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- What is the function of a constant temperature water bath in CO2 absorption kinetics? Achieve High-Precision Research

- What are the performance advantages of using a recirculating cooling system for EK-181 steel? Maximize Yield Strength

- What are the four main types of sensors? A Guide to Power Source and Signal Type

- How does a water bath work? Master Precise and Gentle Heating for Your Lab

- How do circulating cooling systems ensure accuracy in adsorption tests? Stabilize Thermal Variables for Precise Data