In a biology laboratory, an oven is a fundamental piece of equipment used for high-temperature applications, primarily dry heat sterilization and sample dehydration. Unlike a kitchen oven, a lab oven provides precise temperature control and uniform heat distribution, which is critical for reproducible scientific protocols. Its main function is to create a hot, dry environment, making it distinct from other heating devices like incubators or autoclaves.

A laboratory oven uses circulating dry heat to achieve high temperatures, making it essential for sterilizing heat-stable materials like glassware and for precisely drying samples. Its key limitation is that this intense, dry heat will destroy living cells and melt most plastics, defining its specific role in the lab.

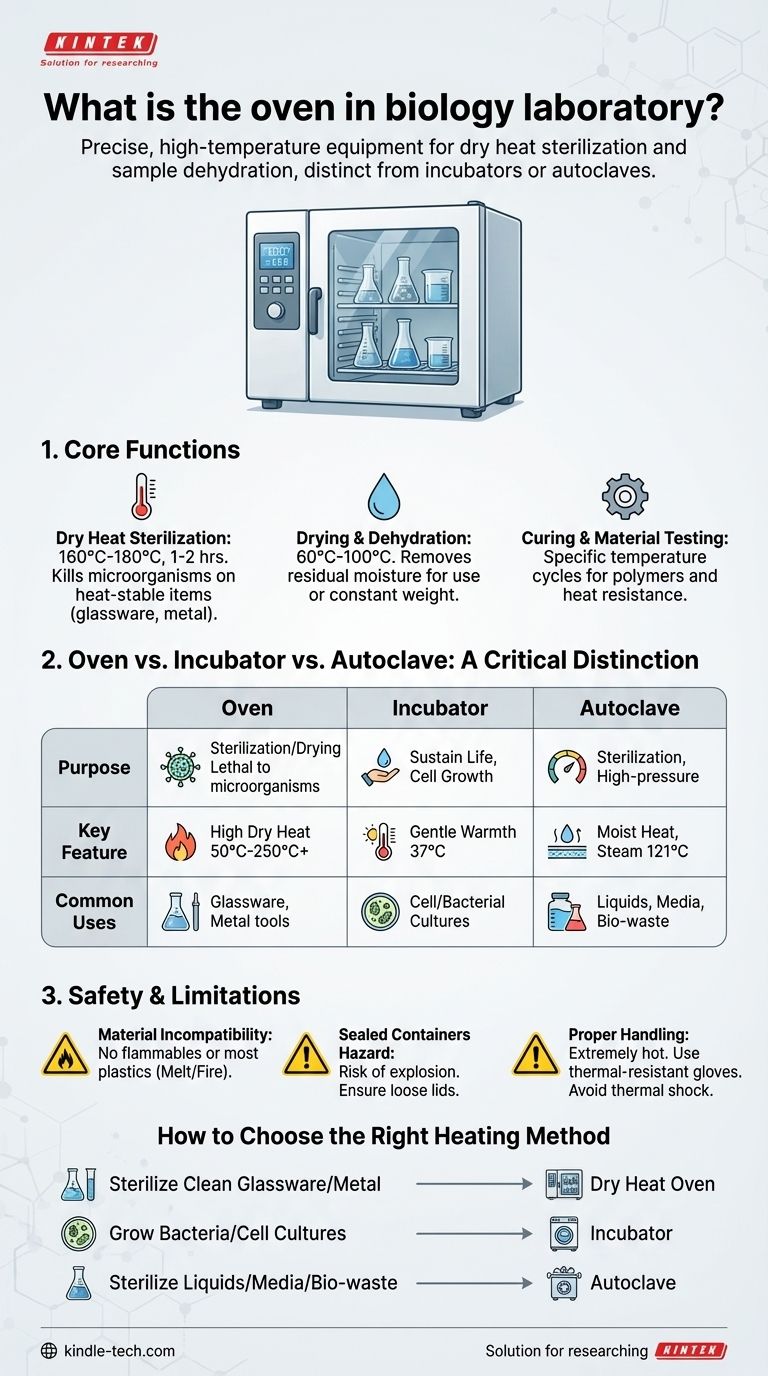

The Core Functions of a Laboratory Oven

A biology lab oven is not a general-purpose heater; it is a specialized tool with a few key applications that rely on its ability to produce high, dry heat.

Dry Heat Sterilization

The most common use for a lab oven is sterilization. By heating items to temperatures between 160°C and 180°C for an extended period (typically 1-2 hours), the intense heat denatures proteins and effectively kills all microorganisms, including bacteria, viruses, and spores.

This method is ideal for items that can withstand high temperatures but could be damaged by moisture, such as glassware (beakers, flasks, pipettes) and metal instruments (forceps, scalpels).

Drying and Dehydration

Another primary function is drying. After glassware is washed, it can be placed in an oven at a moderate temperature (e.g., 60-100°C) to rapidly remove all residual moisture, ensuring it is ready for use.

Ovens are also used in analytical procedures to dehydrate biological or chemical samples to a constant weight. This is critical for experiments where precise mass measurements are required without the variable influence of water content.

Curing and Material Testing

In some specialized applications, ovens are used to cure polymers or other materials that require a specific temperature cycle to set properly. They can also be used for material testing to determine how a substance reacts to prolonged heat exposure.

Oven vs. Incubator vs. Autoclave: A Critical Distinction

A common point of confusion for those new to a lab is differentiating between the three main heating devices. Each serves a unique and non-interchangeable purpose.

The Oven: High-Temperature, Dry Heat

An oven is designed for sterilization and drying, operating at very high temperatures (typically 50°C to over 250°C). Its purpose is to create an environment that is lethal to microorganisms and removes all moisture.

The Incubator: Gentle, Controlled Warmth

An incubator is designed to sustain life. It provides a stable, controlled, and gentle temperature—often around human body temperature (37°C)—to grow and maintain cell cultures, bacterial cultures, or other living specimens. Using an oven instead of an incubator would instantly kill these cultures.

The Autoclave: High-Pressure, Moist Heat

An autoclave is a sterilization device that uses high-pressure steam, typically at 121°C. The combination of moisture and pressure allows heat to penetrate materials much more effectively than dry heat. This makes the autoclave the superior method for sterilizing liquids (like culture media), biohazardous waste, and heat-sensitive plastics.

Understanding the Trade-offs and Safety Protocols

While essential, an oven has clear limitations and presents safety hazards if used improperly. Understanding these is crucial for maintaining a safe and efficient lab environment.

Limitation: Material Incompatibility

Never place flammable or volatile chemicals (like alcohol or solvents) in an oven, as this can cause a fire or explosion. Likewise, most plastics cannot withstand oven temperatures and will melt, releasing toxic fumes and ruining both the item and potentially the oven.

Limitation: Sealed Containers are a Hazard

Placing a tightly sealed container in an oven is extremely dangerous. As the air inside heats up, it expands, which can cause the container to explode violently. Always ensure containers have a loose-fitting lid or are open to the air.

Safety First: Proper Handling

Items removed from a hot oven will be extremely hot and can cause severe burns. Always use thermal-resistant gloves when handling items. Place hot glassware on a heat-proof surface and allow it to cool slowly to prevent thermal shock, which can cause it to shatter.

How to Choose the Right Heating Method

Selecting the correct device is fundamental to the success and safety of your experiment.

- If your primary focus is sterilizing clean glassware or metal instruments: The dry heat oven is a reliable and effective choice.

- If your primary focus is growing bacteria or cell cultures: You must use an incubator to maintain a stable, life-sustaining temperature.

- If your primary focus is sterilizing liquids, culture media, or biohazardous waste: The autoclave is the correct tool, as it uses pressurized steam for rapid and thorough sterilization.

Understanding the specific role of each heating device is fundamental to ensuring safety, accuracy, and reproducibility in the laboratory.

Summary Table:

| Function | Key Features | Common Uses |

|---|---|---|

| Dry Heat Sterilization | 160°C - 180°C, kills microorganisms | Sterilizing glassware, metal tools |

| Drying & Dehydration | Removes moisture, precise temperature control | Drying washed glassware, sample preparation |

| Curing & Material Testing | Uniform heat distribution | Polymer curing, heat resistance testing |

Need a reliable lab oven for your biology lab? KINTEK specializes in high-performance laboratory equipment, including ovens designed for precise sterilization and drying. Our products ensure safety, accuracy, and reproducibility for your critical experiments. Contact us today to find the perfect oven for your laboratory needs!

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

People Also Ask

- What is AC frame? Decoding the Two Meanings in Wi-Fi and Video

- What is the temperature of a lab oven? A Guide to Selecting the Right Type for Your Application

- What is a lab oven used for? A Guide to Precise Heating, Sterilization & Drying

- What kind of oven is used for drying? Discover the Precision of a Laboratory Drying Oven

- What is a lab drying oven used for? Master Moisture Removal & Sterilization for Your Lab