In essence, a laboratory oven is a high-precision tool for controlled heating. Its primary functions include sterilizing equipment, drying glassware, removing solvents, and performing thermal processing like curing or annealing on materials. Unlike a kitchen oven, its value lies in maintaining an extremely uniform and stable temperature throughout its chamber for specific periods.

A lab oven is not simply a box that gets hot. It is an instrument engineered to create a highly controlled thermal environment, ensuring that processes like sterilization, drying, and material curing are repeatable, reliable, and uniform.

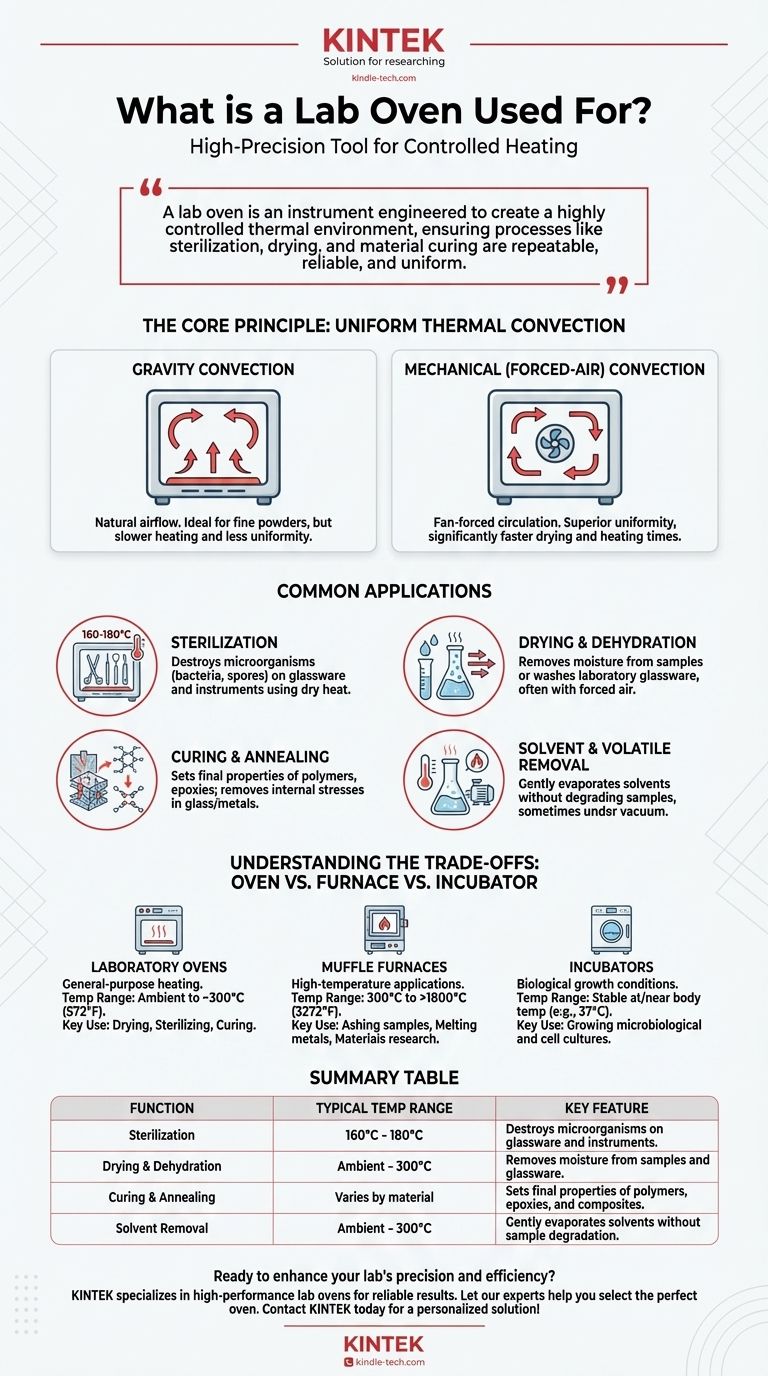

The Core Principle: Uniform Thermal Convection

A laboratory oven's primary purpose is to deliver precise, consistent heat. This is achieved through controlled convection, the movement of hot air.

Gravity Convection

In a gravity convection oven, air is heated by elements at the bottom. As the air heats, it becomes less dense and rises, displacing cooler, denser air which then sinks to be heated. This creates a natural, gentle airflow.

These ovens are ideal for drying fine powders or materials that could be disturbed by forced air. However, they are slower to heat and can have less temperature uniformity than their mechanical counterparts.

Mechanical (Forced-Air) Convection

Mechanical convection ovens use a fan to actively circulate the heated air throughout the chamber. This forced circulation ensures a much higher degree of temperature uniformity and significantly faster drying and heating times.

This design is the standard for most applications, including sterilization and curing, where ensuring the entire sample reaches the target temperature is critical.

Common Applications in Detail

The oven's ability to maintain a stable thermal environment enables several key laboratory processes.

Sterilization

Dry heat sterilization is a common use for lab ovens. By holding glassware or metal instruments at a high temperature (e.g., 160-180°C) for a defined period, all microorganisms, including bacteria and spores, are destroyed.

Drying and Dehydration

Ovens are essential for removing moisture from samples before weighing (e.g., for gravimetric analysis) or for drying laboratory glassware after washing. A forced-air oven excels at this by constantly circulating dry, hot air over the items.

Curing and Annealing

Many materials, such as polymers, epoxies, and composites, require a "curing" process where they are held at a specific temperature to achieve their final chemical and physical properties. Similarly, "annealing" involves heating and slowly cooling glass or metals to remove internal stresses and increase ductility.

Solvent and Volatile Removal

In chemical synthesis or sample preparation, it's often necessary to evaporate a solvent or other volatile compounds from a sample without degrading it. A lab oven provides the gentle, consistent heat needed for this process, often under vacuum in specialized models.

Understanding the Trade-offs: Oven vs. Furnace vs. Incubator

Confusing these instruments is a common and costly mistake. Each is designed for a fundamentally different purpose.

Laboratory Ovens

These are general-purpose heating instruments typically operating from slightly above ambient temperature to around 300°C (572°F). Their strength is stable, uniform heat for drying, sterilizing, and curing.

Muffle Furnaces

Furnaces operate at much higher temperatures, often from 300°C to over 1,800°C (3,272°F). They are used for applications like ashing samples (burning off organic material), melting metals, or high-temperature materials science research. Using an oven for a furnace application will destroy the oven.

Incubators

Incubators are designed for the opposite end of the spectrum. They maintain stable temperatures at or near body temperature (e.g., 37°C) to grow and maintain microbiological cultures or cell cultures. An oven lacks the fine control at these low temperatures and would kill the samples.

Choosing the Right Heating Method

Your specific goal dictates which instrument is appropriate.

- If your primary focus is sterilizing equipment or drying glassware: A standard mechanical convection lab oven is your primary tool.

- If your primary focus is removing solvents or curing polymers: A forced-air oven provides the uniform and stable heat required for reliable results.

- If your primary focus is growing and maintaining biological cultures: You must use an incubator, as an oven's temperature range will destroy your samples.

- If your primary focus is ashing a sample or testing materials above 300°C: You absolutely require a high-temperature furnace.

Selecting the correct thermal instrument is the first step toward ensuring your procedure is safe, efficient, and scientifically valid.

Summary Table:

| Function | Typical Temperature Range | Key Feature |

|---|---|---|

| Sterilization | 160°C - 180°C | Destroys microorganisms on glassware and instruments. |

| Drying & Dehydration | Ambient - 300°C | Removes moisture from samples and glassware. |

| Curing & Annealing | Varies by material | Sets final properties of polymers, epoxies, and composites. |

| Solvent Removal | Ambient - 300°C | Gently evaporates solvents without sample degradation. |

Ready to enhance your lab's precision and efficiency? The right thermal equipment is critical for reliable sterilization, drying, and curing processes. At KINTEK, we specialize in providing high-performance lab ovens and consumables tailored to your specific laboratory needs. Let our experts help you select the perfect oven to ensure uniform heating and repeatable results. Contact KINTEK today to discuss your application and get a personalized solution!

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- 1200℃ Muffle Furnace Oven for Laboratory

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- Why is a hydrogen and water vapor (H2/H2O) gas manifold system necessary for LBE corrosion control? Precision Analysis

- Why is it necessary to use a mechanical stirrer or shaker during azo dye degradation experiments? Optimize Your Results

- Which is a disadvantage of the carburizing process? High Costs, Complex Control, and Post-Processing Demands

- What are the two main configurations of ULT freezers? Upright vs. Chest for Your Lab's Needs

- What are the three types of tempering? Choose the Right Process for Hardness vs. Toughness

- What is a thick film circuit? A Durable, High-Power Hybrid Electronics Solution

- How is temperature controlled in an experiment? Master Precision, Stability, and Uniformity

- Why is pyrolysis of solid waste important? Transform Waste into Fuel and Valuable Resources